VPAK PP FEB-2023 95214200_13

Single Package Vertical Heat Pumps

18000 & 24000 BTU models use secondary gravity-fed

drain (VPDP2).

VERT-I-PAK

®

PRODUCT PROFILE

THE EXPERTS IN ROOM AIR CONDITIONING

PRODUCT PROFILE

2

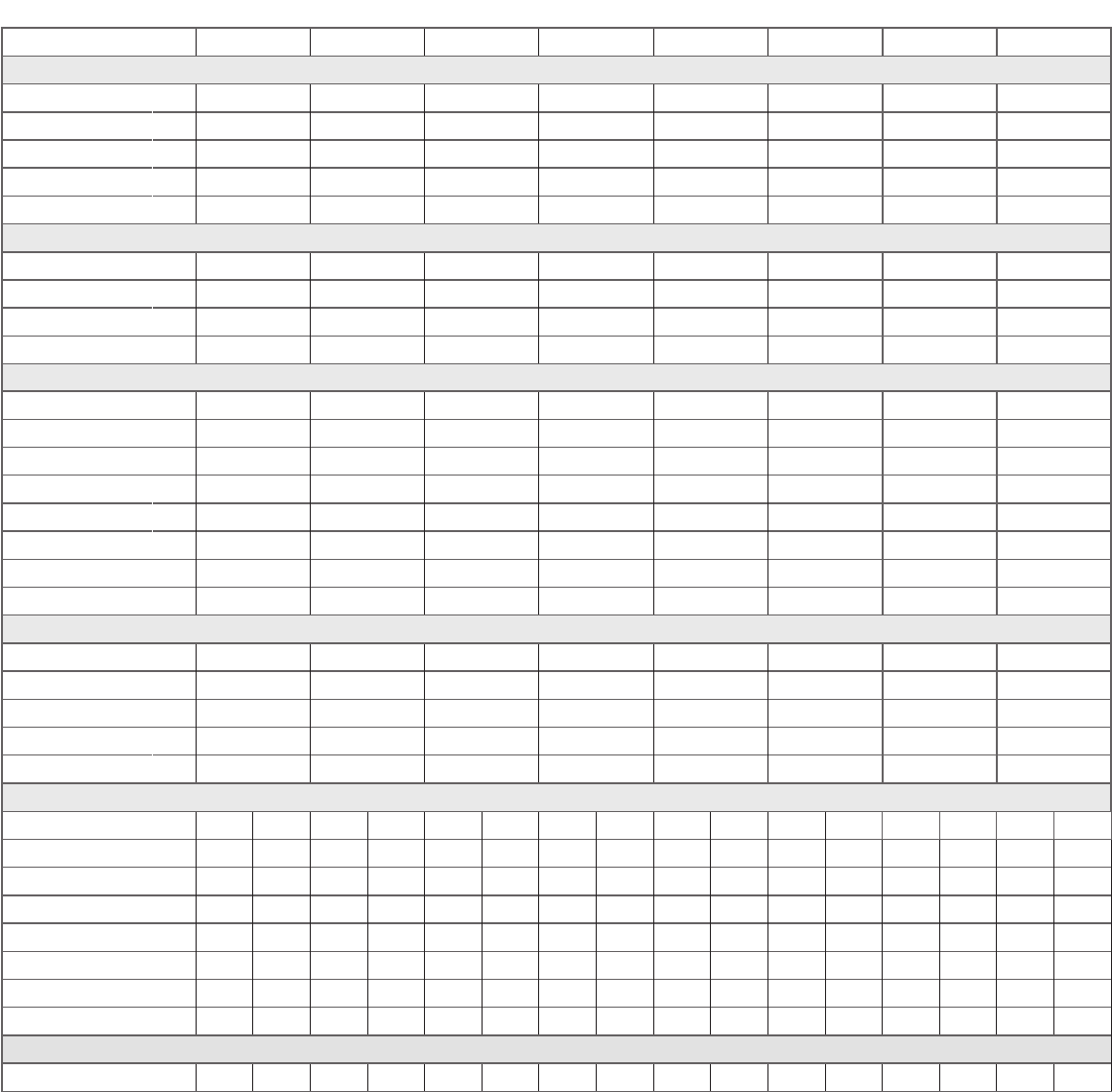

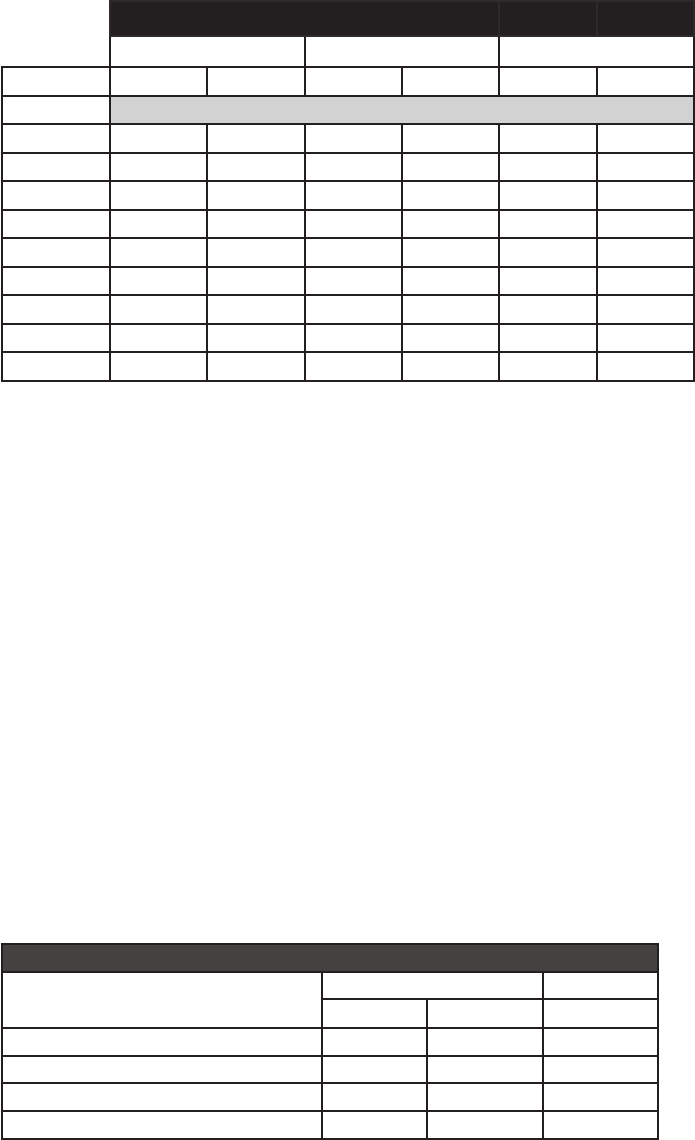

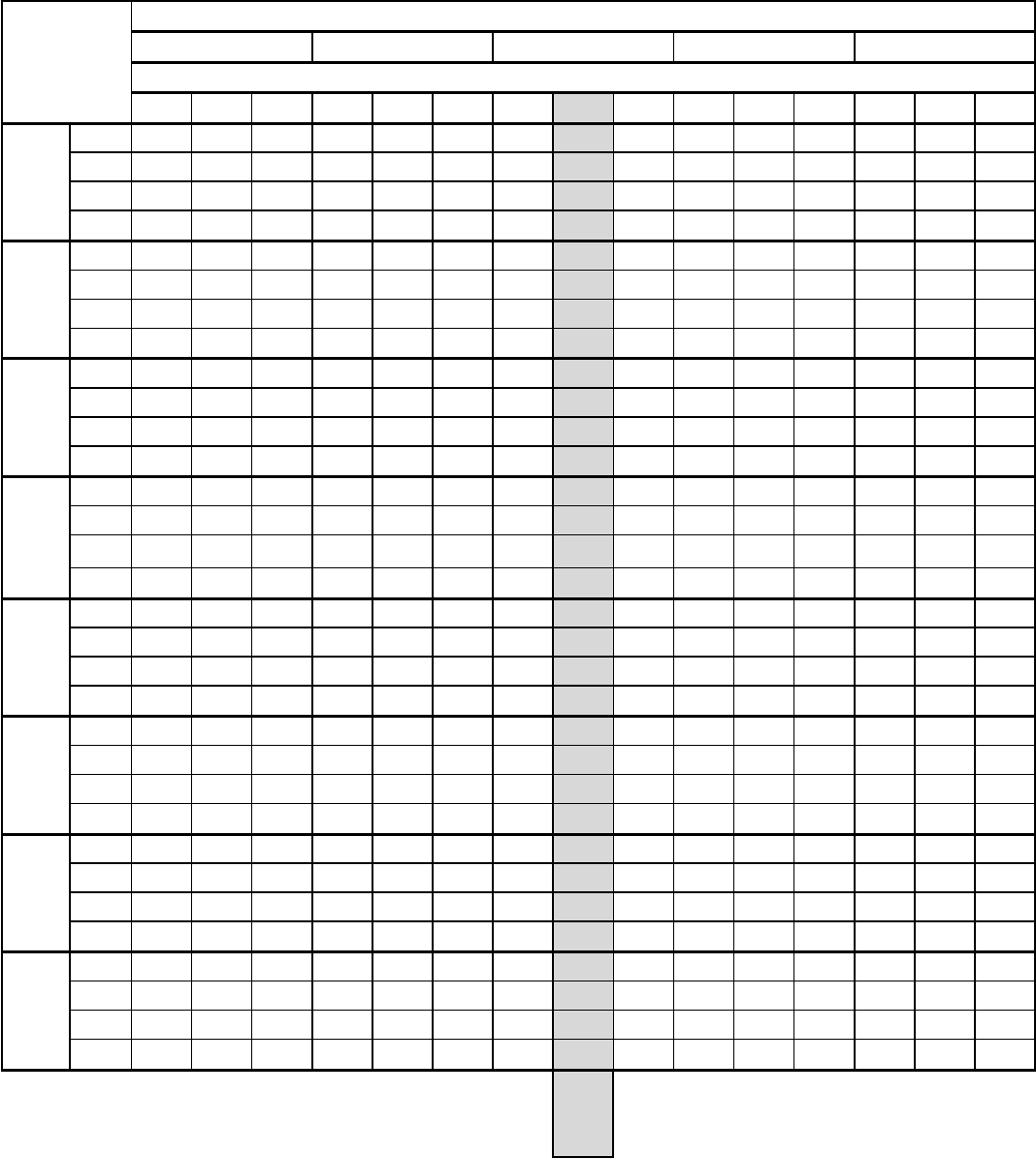

CHASSIS SPECIFICATIONS K-Series models 230/208V, R-Series models 265V

MODEL

VHA09K VHA09R VHA12K VHA12R VHA18K VHA18R VHA24K VHA24R

COOLING DATA

TOTAL COOLING CAP.

9300 9300 11500 11500 18400 18400 22500 22500

SENSIBLE COOL CAP.

7440 7440 9085 9085 13430 13430 15750 15750

POWER (W)

845 845 1045 1045 1670 1670 2045 2045

EER

11.0 11.0 11.0 11.0 11.0 11.0 11.0 11.0

HEATER SIZE (kW)

2.5/3.4/5.0 2.5/3.4/5.0 2.5/3.4/5.0 2.5/3.4/5.0 2.5/3.4/5.0/7.5 2.5/3.4/5.0/7.5 2.5/3.4/5.0/7.5/10.0 2.5/3.4/5.0/7.5/10.0

HEAT PUMP DATA

REVERSE HEATING BTU

8300 8300 10600 10600 16700 16700 19500 19500

COP @ 47F

3.3 3.3 3.3 3.3 3.3 3.3 3.3 3.3

HEATING POWER (W)

730 730 940 940 1480 1480 1732 1732

HEATING CURRENT (A)

3.6 3.1 4.5 3.7 7.0 6.1 9.2 9.2

ELECTRICAL DATA

VOLTAGE (1 PHASE, 60 HZ)

208-230 265 208-230 265 208-230 265 208-230 265

VOLT RANGE

197-253 239-292 197-253 239-292 197-253 239-292 197-253 239-292

COOLING CURRENT (A)

4.1 3.5 4.9 4.0 7.9 7.0 10.5 10.5

AMPS L.R

21.0 21.0 23.0 23.0 37.0 37.0 44.0 44.0

INDOOR MOTOR (HP)

1/4 1/4 1/4 1/4 1/4 1/4 1/5 1/5

INDOOR MOTOR (A)

1.2 1.2 1.2 1.2 0.42 0.42 1.4 1.4

OUTDOOR MOTOR (HP)

— — — — 1/4 1/4 1/4 1/4

OUTDOOR MOTOR (A)

— — — — 1.6 1.6 1.7 1.7

PHYSICAL

DIMENSIONS (W X D X H)

23”x23”x32” 23”x23”x32” 23”x23”x32” 23”x23”x32” 23”x23”x47” 23”x23”x47” 23”x23”x52” 23”x23”x52”

NET WEIGHT (LBS)

142 144 147 149 190 192 225 227

SHIPPING WEIGHT (LBS)

164 166 169 171 216 218 251 253

TEST SETTING

LOW LOW LOW LOW LOW LOW LOW LOW

R410A CHARGE (OZ)

38.0 38.0 42.1 42.1 57.0 57.0 62 62

AIRFLOW DATA

INDOOR CFM

LOW HIGH LOW HIGH LOW HIGH LOW HIGH LOW HIGH LOW HIGH LOW HIGH LOW HIGH

.10” ESP

430 490 430 490 430 490 430 490 630 675 630 675 660 700 660 700

.15” ESP

410 470 410 470 410 470 410 470 595 640 595 640 615 665 615 665

.20” ESP

360 440 360 440 360 440 360 440 550 600 550 600 575 625 575 625

.25” ESP

310 400 310 400 310 400 310 400 505 550 505 550 525 580 525 580

.30” ESP

260 350 260 350 260 350 260 350 455 500 455 500 485 540 485 540

.35" ESP

-

-

-

-

-

-

-

-

400 445 400 445 450 500 450 500

.40" ESP

-

-

-

-

-

-

-

-

345 400 345 400 415 465 415 465

VENT CFM

UP TO " " CFM

60

60

60

60

60

60

60

60

60 60 60 60 60 60 60 60

NOTES:

Cooling Standards: 95°F DB/75°F WB OUTDOOR, 80°F DB/67°F WB INDOOR

Heating Standards: 47°F DB/43°F WB OUTDOOR, 70°F DB/60°F WB INDOOR

Normal Value Wet Coil @ .1” ESP.

Rated CFM at Low Speed: VHA09 - 430 CFM VHA12 - 430 CFM

VHA18 - 630 CFM VHA24 - 655 CFM

Due to continuing research in new energy-saving technology, specications are subject to change without notice.

3

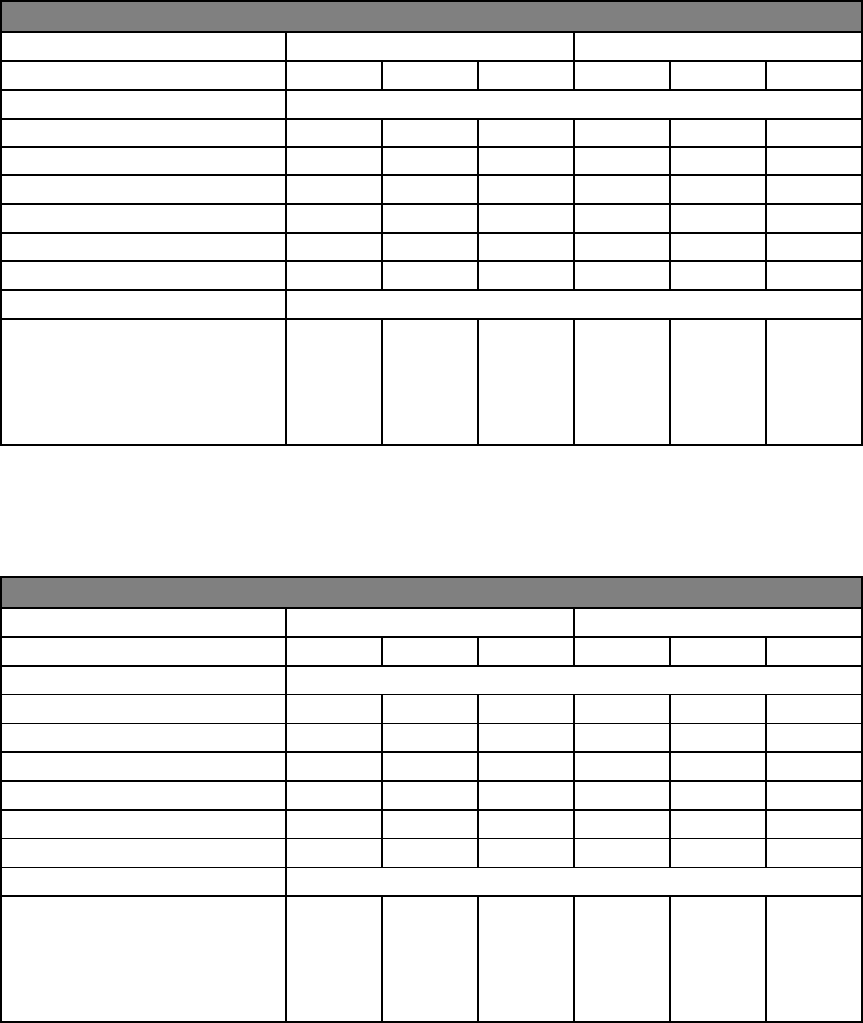

SMALL CHASSIS ELECTRICAL DATA

ELECTRICAL DATA

VHA09K VHA12K

HEATER WATTS 2050-2500 2780-3400 4090-5000 2050-2500 2780-3400 4090-5000

VOLTAGE 208-230

ELECTRIC HEATING BTU 7000-8500 9500-11600 13900-17000 7000-8500 9500-11600 13900-17000

ELEC. HEATING CURRENT (AMPS) 11.5-12.5 15.0-16.4 21.3-23.3 11.5-12.5 15.0-16.4 21.3-23.3

MINIMUM CIRCUIT AMPACITY 16.0 20.9 29.6 16.0 20.9 29.6

BRANCH CIRCUIT FUSE (AMPS) 20 25 30 20 25 30

LRA-COMPRESSOR (AMPS) 21.0 21.0 21.0 23.0 23.0 23.0

BASIC HEATER SIZE 2.5KW 3.4KW 5.0KW 2.5KW 3.4KW 5.0KW

POWER CONNECTION HARD WIRED HARD WIRED

RECOMMENDED BRANCH

CIRCUIT WIRE SIZES

*AWG- AMERICAN WIRE GAUGE

12 12 10 12 12 10

ELECTRICAL DATA

VHA09R VHA12R

HEATER WATTS 2500 3400 5000 2500 3400 5000

VOLTAGE 265

ELECTRIC HEATING BTU 8500 11600 17000 8500 11600 17000

ELEC. HEATING CURRENT (AMPS) 11 14.4 20.5 11 14.4 20.5

MINIMUM CIRCUIT AMPACITY 14.2 18.5 26 14.2 18.5 26

BRANCH CIRCUIT FUSE (AMPS) 15 20 30 15 20 30

LRA-COMPRESSOR (AMPS) 21.0 21.0 21.0 23.0 23.0 23.0

BASIC HEATER SIZE 2.5KW 3.4KW 5.0KW 2.5KW 3.4KW 5.0KW

POWER CONNECTION HARD WIRED HARD WIRED

RECOMMENDED BRANCH

CIRCUIT WIRE SIZES

*AWG- AMERICAN WIRE GAUGE

14 12 10 12 12 10

4

Due to continuing research in new energy-saving technology, specications are subject to change without notice.

LARGE CHASSIS ELECTRICAL DATA

ELECTRICAL DATA

VHA18K VHA24K

HEATER WATTS 2050-2500 2780-3400 4090-5000 6135-7500 2050-2500 2780-3400 4090-5000 6135-7500 8180-10000

VOLTAGE 208-230

ELECTRIC HEATING BTU 7000-8500 9500-11600 13900-17000 20900-25600 7000-8500 9500-11600 13900-17000 20900-25600 27900-34100

ELEC. HEATING CURRENT (AMPS) 11.5-12.5 15.0-16.4 21.3-23.3 31.1-34.2 11.3-12.3 14.8-16.2 21.1-23.1 30.9-34.0 40.7-44.9

MINIMUM CIRCUIT AMPACITY 15.6 20.5 29.2 42.8 15.4 20.3 29.0 42.6 56.1

BRANCH CIRCUIT FUSE (AMPS) 20 25 30 45 20 25 30 45 60

LRA-COMPRESSOR (AMPS) 37.0 37.0 37.0 37.0 44.0 44.0 44.0 44.0 44.0

BASIC HEATER SIZE 2.5KW 3.4KW 5.0KW 7.5KW 2.5KW 3.4KW 5.0KW 7.5K W 10.0KW

POWER CONNECTION HARD WIRED HARD WIRED

RECOMMENDED BRANCH

CIRCUIT WIRE SIZES

*AWG- AMERICAN WIRE GAUGE

12 12 10 6 12 10 10 6 4

ELECTRICAL DATA

VHA18R VHA24R

HEATER WATTS 2500 3400 5000 7500 2500 3400 5000 7500 10000

VOLTAGE 265

ELECTRIC HEATING BTU 8500 11600 17000 25600 8500 11600 17000 25600 34100

ELEC. HEATING CURRENT (AMPS) 10.5 13.9 19.9 29.9 10.8 14.2 20.3 29.7 39.1

MINIMUM CIRCUIT AMPACITY 13.8 18.0 25.7 37.4 13.6 17.8 25.4 37. 2 49.0

BRANCH CIRCUIT FUSE (AMPS) 15 20 30 40 20 20 30 40 50

LRA-COMPRESSOR (AMPS) 37.0 37.0 37.0 37.0 44.0 44.0 44.0 44.0 44.0

BASIC HEATER SIZE 2.5KW 3.4KW 5.0KW 7.5KW 2.5KW 3.4KW 5.0KW 7.5K W 10.0KW

POWER CONNECTION HARD WIRED HARD WIRED

RECOMMENDED BRANCH

CIRCUIT WIRE SIZES

*AWG- AMERICAN WIRE GAUGE

14 12 10 6 12 12 10 6 4

5

AIRFLOW DATA

Indoor CFM & External Static Pressure

Model

VHA09/VHA12 VHA18 VHA24

Fan Speed Low High Low High Low High

ESP (“) SCFM

0.0” 470

520 730 800 755 805

0.05” 460

510 670 735 700 750

0.10” 430

490 630 675 660 700

0.15” 410 470 595 640 615 665

0.20” 360 440 550 600 575 625

0.25”

310

400 505 550 525 580

0.30” 260 350 455 500 485 540

0.35” -- -- 400 445 450 500

0.40” -- -- 345 400 415 465

Indoor air ow may be determined by measuring the external static pressure (ESP) of the duct system using an inclined

manometer or magnahelic gauge and consulting the above chart to derive actual air ow. Under no circumstances

should the small chassis Vert-I-Pak equipment be operated at an external static pressure in excess of 0.3” W.C. on the

VHA09 & VHA12 and 0.4”W.C. on the VHA18 & VHA24. Operation of the Vert-I-Pak under these conditions will result in

inadequate air ow, leading to poor performance and/or premature component failure.

Control

For LOW speed only operation, connect the fan output terminal from the thermostat to the GL terminal of the electronic

control.

For HIGH speed only operation, connect the fan output terminal from the thermostat to the GH terminal of the electronic

control.

For thermostats with two-speed capability, connect the LOW speed output to the GL terminal and the HIGH speed output

to the GH terminal.

NOTE: Any non-Friedrich thermostat of low voltage device being powered by the Vert-I-Pak will need to be reviewed and

approved for use.

Condenser External Static Pressure

Model

Design Maximum

CFM

ESP ("WC) ESP ("WC)

VHA09 650 0.03 0.12

VHA12 650 0.03 0.12

VHA18 950 0.03 0.12

VHA24 980 0.03 0.12

Condenser CFM & External Static Pressure

VPAK is designed to install through an exterior wall with a plenum (VPAWP-8, VPAWP-14) and a Friedrich external louver .

If the Friedrich designed plenum and louver combinations are not used, the selections and design must be evaluated by Friedrich to ensure the

total pressure drop does not exceed the maximum allowable limits.

6

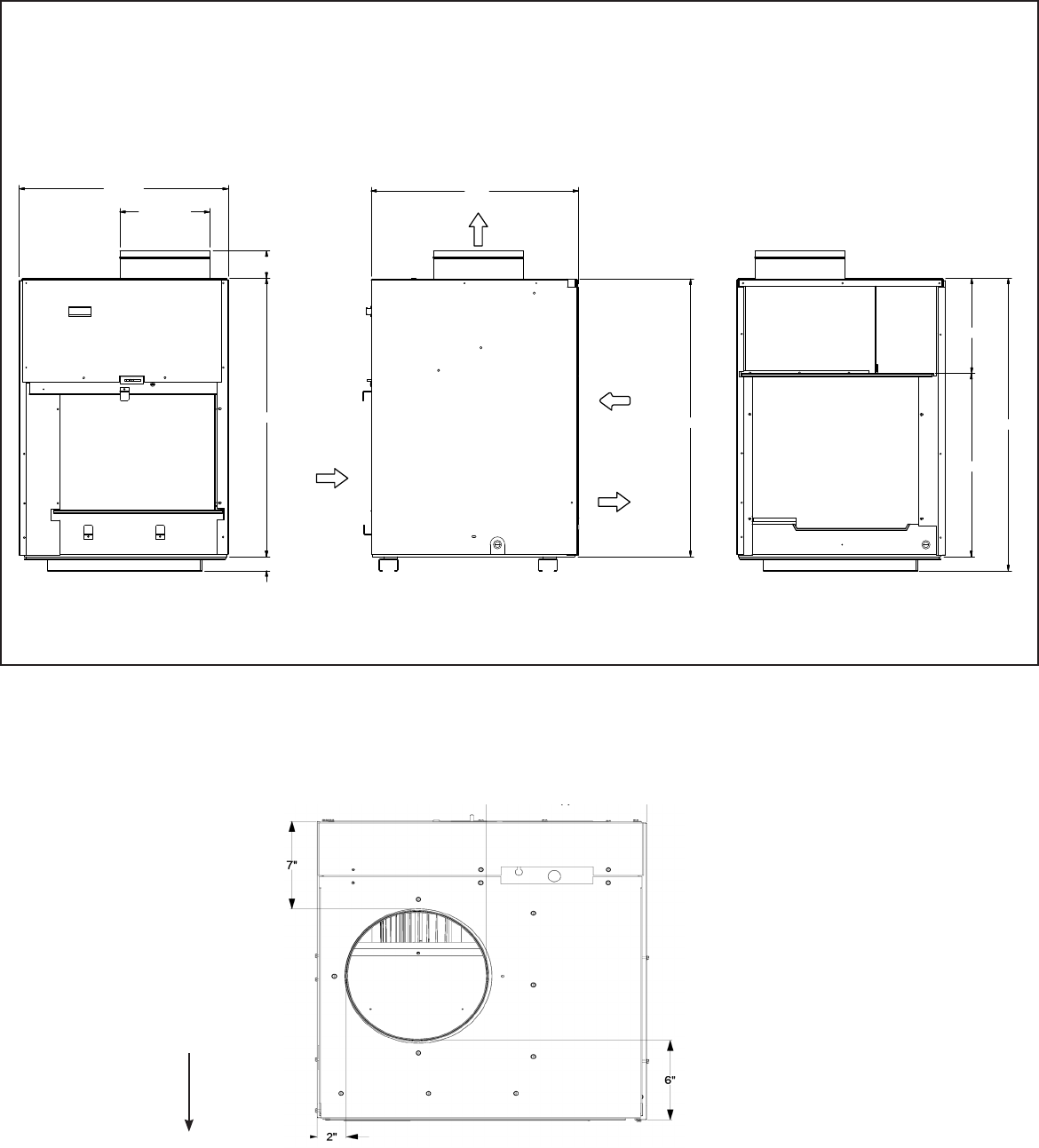

UNIT CHASSIS DIMENSIONS - VHA09 & VHA12

DUCT

DIAMETER

SUPPLY

AIR

CONDENSER

INLET AIR

CONDENSER

EXHAUST

AIR

RETURN

AIR

Front Side Rear

23 1/8”

10”

2 15/16”

29 1/2”

29 1/2”

1 1/2”

23 1/8”

10 1/8”

19 1/2”

31”

Outside Wall

UNIT TOP VIEW DIMENSIONS

7

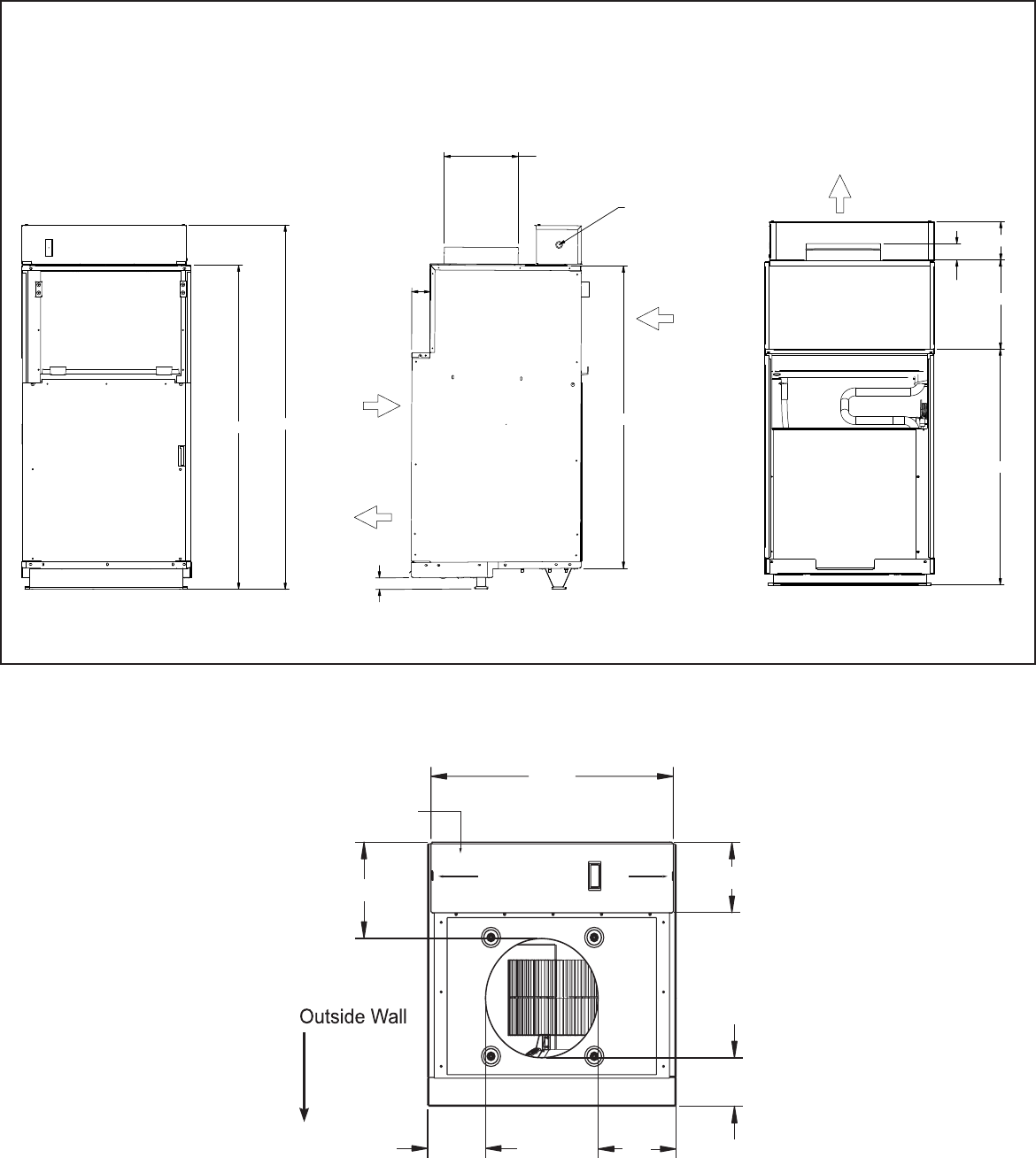

UNIT CHASSIS DIMENSIONS - VHA18

42 5/8”

39 3/4”

2 3/16”

5 1/16”

31”

11 11/16”

47 15/16”

2 1/2

10”

DUCT

DIAMETER

SUPPLY

AIR

RETURN

AIR

CONDENSER

INLET

AIR

ELECTRICAL

ENTRY

BOTH SIDES

CONDENSER

EXHAUST

AIR

FRONT

SIDE

REAR

1 1/2”

Lorem ipsum

UNIT TOP VIEW DIMENSIONS

electrical

entrance

control box

22

5

/

16

"

8

3

/

8

"

6

3

/

16

"

4

3

/

16

"

7

3

/

16

"

5

5

/

16

"

8

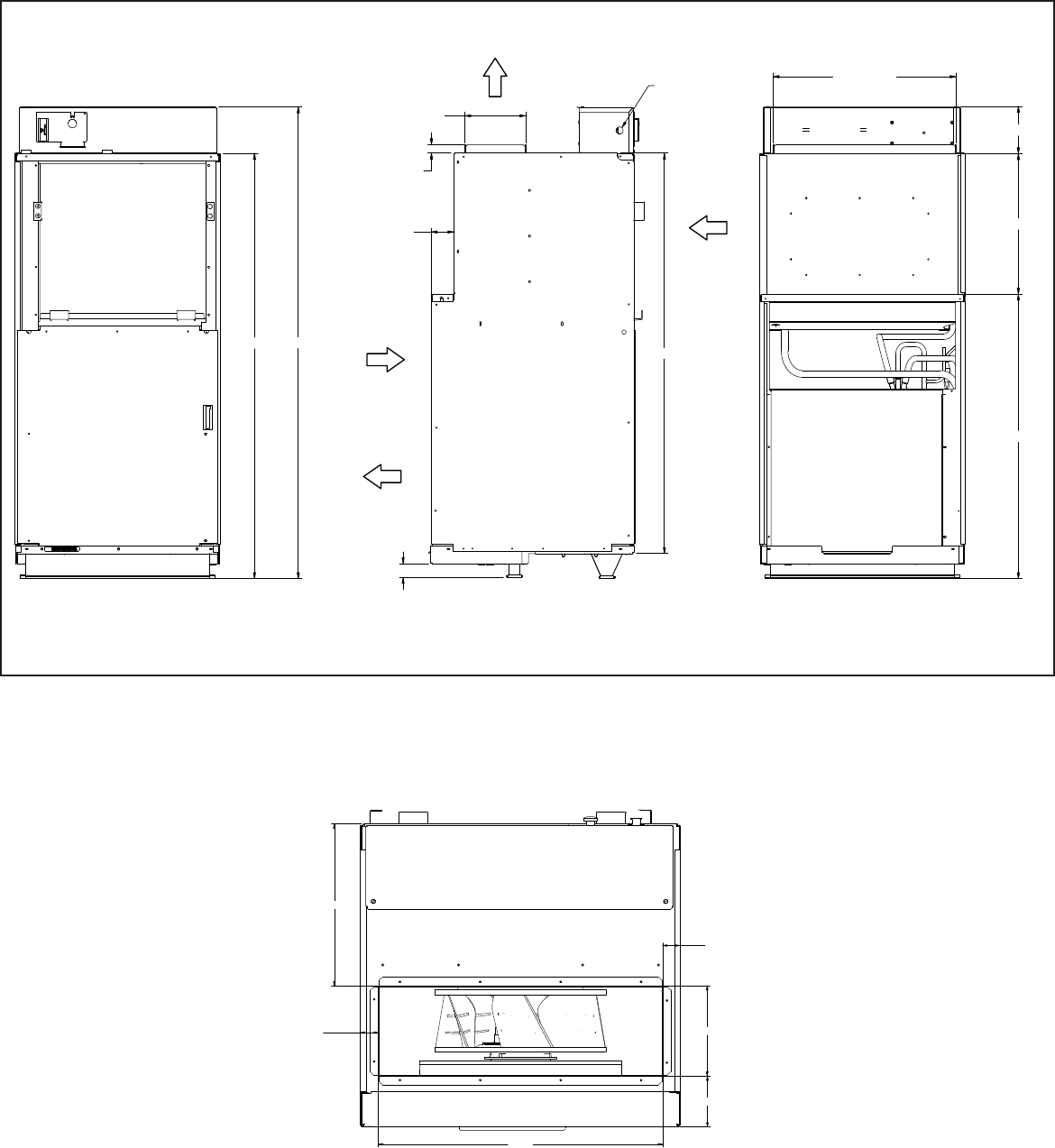

UNIT CHASSIS DIMENSIONS - VHA24

46

11/16"

51 3/4"

1 1/2

"

44

2 1/2

"

CONDENSER

INLET

AIR

CONDENSER

EXHAUST

AIR

FRONT

SIDE

REAR

6 55/64

"

DUCT

1

"

DUCT

ELECTRICAL

ENTRY

BOTH SIDES

RETURN

AIR

15

11

/16

"

3

1"

5

1/6"

20 5/8

"

DUCT

SUPPLY

AIR

UNIT TOP VIEW DIMENSIONS

P

A

R

T

N

O

.

3 55/64

1 1/2

"

12 19/64

"

1 1/2

"

6 55/64

"

20 5/8

"

Outside Wall

9

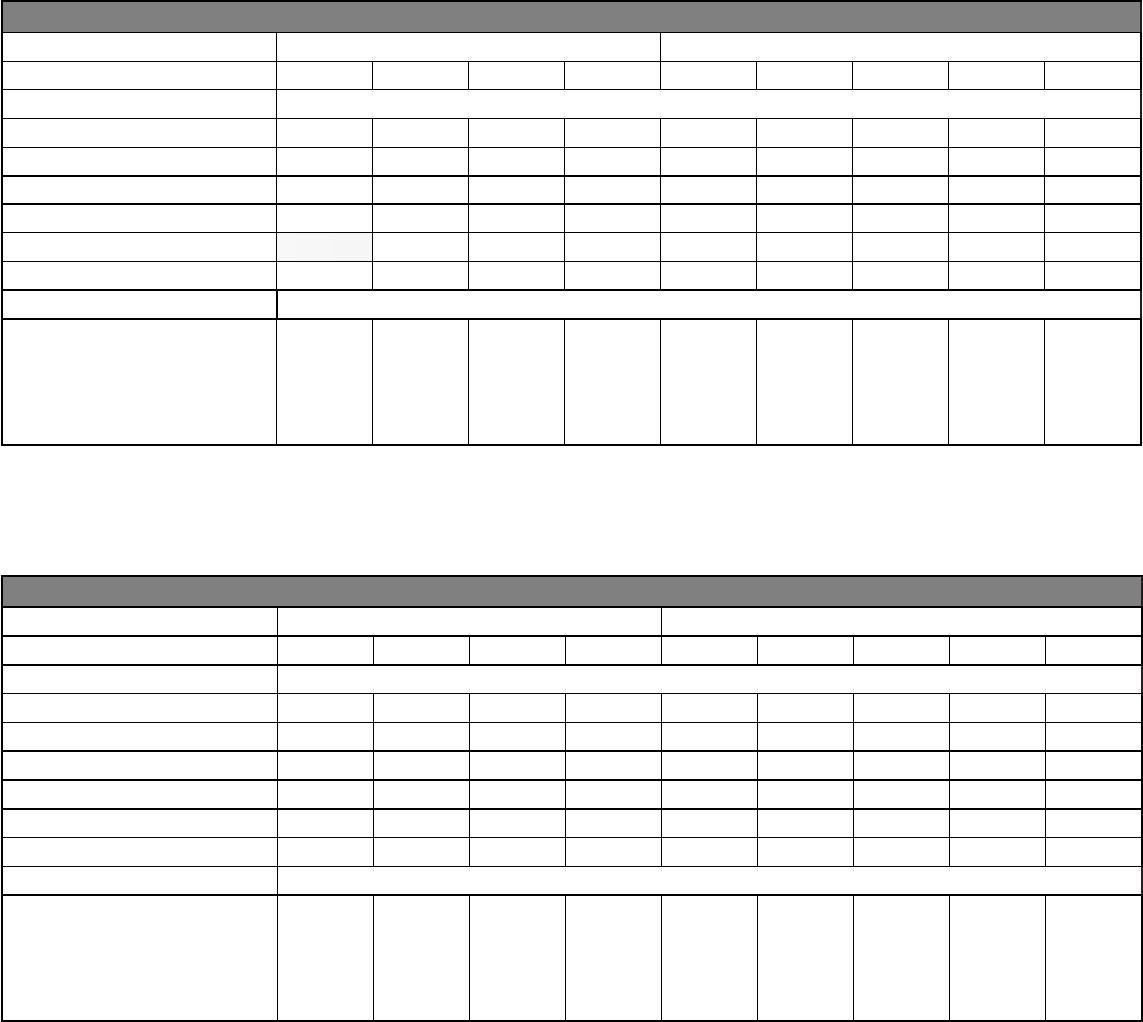

EXTENDED COOLING PERFORMANCE

OUTDOOR DRY BULB TEMP. (DEGREES F AT 40% R.H.)

75 85 95 105 115

INDOOR WET BULB TEMP. (DEGREES F AT 80 F D.B.)

62 67 72 62 67 72 62 67 72 62 67 72 62 67 72

VHA09K

BTUH 9485 10084 10408 8949 9776 10216 8427 9300 9879 7914 8686 9409 7373 7986 8821

WATTS 728 738 745 773 789 798 820 845 858 876 904 923 938 965 991

AMPS 3.6 3.6 3.6 3.7 3.8 3.8 4.0 4.1 4.2 4.3 4.4 4.5 4.6 4.7 4.8

SHR 0.99 0.73 0.55 1.00 0.77 0.56 1.00 0.80 0.57 1.00 0.83 0.58 1.00 0.87 0.60

VHA12K

BTUH 11608 12169 12488 11218 11916 12319 10763 11500 11975 10304 10962 11476 9785 10339 10847

WATTS 877 886 893 953 970 979 1023 1045 1059 1092 1114 1132 1158 1178 1199

AMPS 4.1 4.2 4.2 4.5 4.5 4.6 4.8 4.9 5.0 5.1 5.2 5.3 5.4 5.5 5.6

SHR 0.99 0.74 0.55 1.00 0.77 0.56 1.00 0.79 0.57 1.00 0.81 0.58 1.00 0.84 0.58

VHA18K

BTUH 18512 19518 20299 17915 19060 19912 17107 18400 19319 16156 17583 18552 15187 16641 17641

WATTS 1401 1423 1446 1520 1552 1580 1624 1673 1704 1719 1786 1824 1819 1893 1938

AMPS 6.6 6.7 6.8 7.2 7.3 7.5 7.7 7.9 8.0 8.1 8.4 8.6 8.6 8.9 9.2

SHR 0.91 0.70 0.52 0.94 0.71 0.53 0.96 0.73 0.54 1.00 0.75 0.54 1.00 0.77 0.55

VHA24K

BTUH 23555 24762 25388 22096 23348 24301 21020 22500 23530 19830 21403 22745 19051 20337 21225

WATTS 1824 1866 1921 1963 2003 2048 2005 2045 2072 2021 2092 2140 2228 2311 2357

AMPS 9 9.2 9.4 9.6 9.8 10 10.2 10.5 10.7 10.7 11.1 11.3 11.4 11.8 12.1

SHR 0.87 0.66 0.49 0.88 0.68 0.5 0.91 0.7 0.51 0.96 0.72 0.5 0.99 0.75 0.5

VHA09R

BTUH 9485 10084 10408 8949 9776 10216 8427 9300 9879 7914 8686 9409 7373 7986 8821

WATTS 728 738 745 773 789 798 820 845 858 876 904 923 938 965 991

AMPS 3.1 3.1 3.1 3.2 3.3 3.3 3.5 3.5 3.6 3.7 3.8 3.9 4.0 4.1 4.2

SHR 0.99 0.73 0.55 1.00 0.77 0.56 1.00 0.80 0.57 1.00 0.83 0.58 1.00 0.87 0.60

VHA12R

BTUH 11608 12169 12488 11218 11916 12319 10763 11500 11975 10304 10962 11476 9785 10339 10847

WATTS 877 886 893 953 970 979 1023 1045 1059 1092 1114 1132 1158 1178 1199

AMPS 3.4 3.4 3.4 3.6 3.7 3.7 3.9 4.0 4.1 4.2 4.3 4.3 4.4 4.5 4.6

SHR 0.99 0.74 0.55 1.00 0.77 0.56 1.00 0.79 0.57 1.00 0.81 0.58 1.00 0.84 0.58

VHA18R

BTUH 18512 19518 20299 17915 19060 19912 17107 18400 19319 16156 17583 18552 15187 16641 17641

WATTS 1401 1423 1446 1520 1552 1580 1624 1673 1704 1719 1786 1824 1819 1893 1938

AMPS 5.9 6 6.1 6.4 6.5 6.6 6.8 7.0 7.1 7.2 7.5 7.6 7.6 7.9 8.1

SHR 0.91 0.70 0.52 0.94 0.71 0.53 0.96 0.73 0.54 1.00 0.75 0.54 1.00 0.77 0.55

VHA24R

BTUH 23555 24762 25388 22096 23348 24301 21020 22500 23530 19830 21403 22745 19051 20337 21225

WATTS 1824 1866 1921 1963 2003 2048 2005 2045 2072 2021 2092 2140 2228 2311 2357

AMPS 9 9.2 9.4 9.6 9.8 10 10.2 10.5 10.7 10.7 11.1 11.3 11.4 11.8 12.1

SHR 0.87 0.66 0.49 0.88 0.68 0.5 0.91 0.7 0.51 0.96 0.72 0.5 0.99 0.75 0.5

RATING

POINT

AHRI

390

10

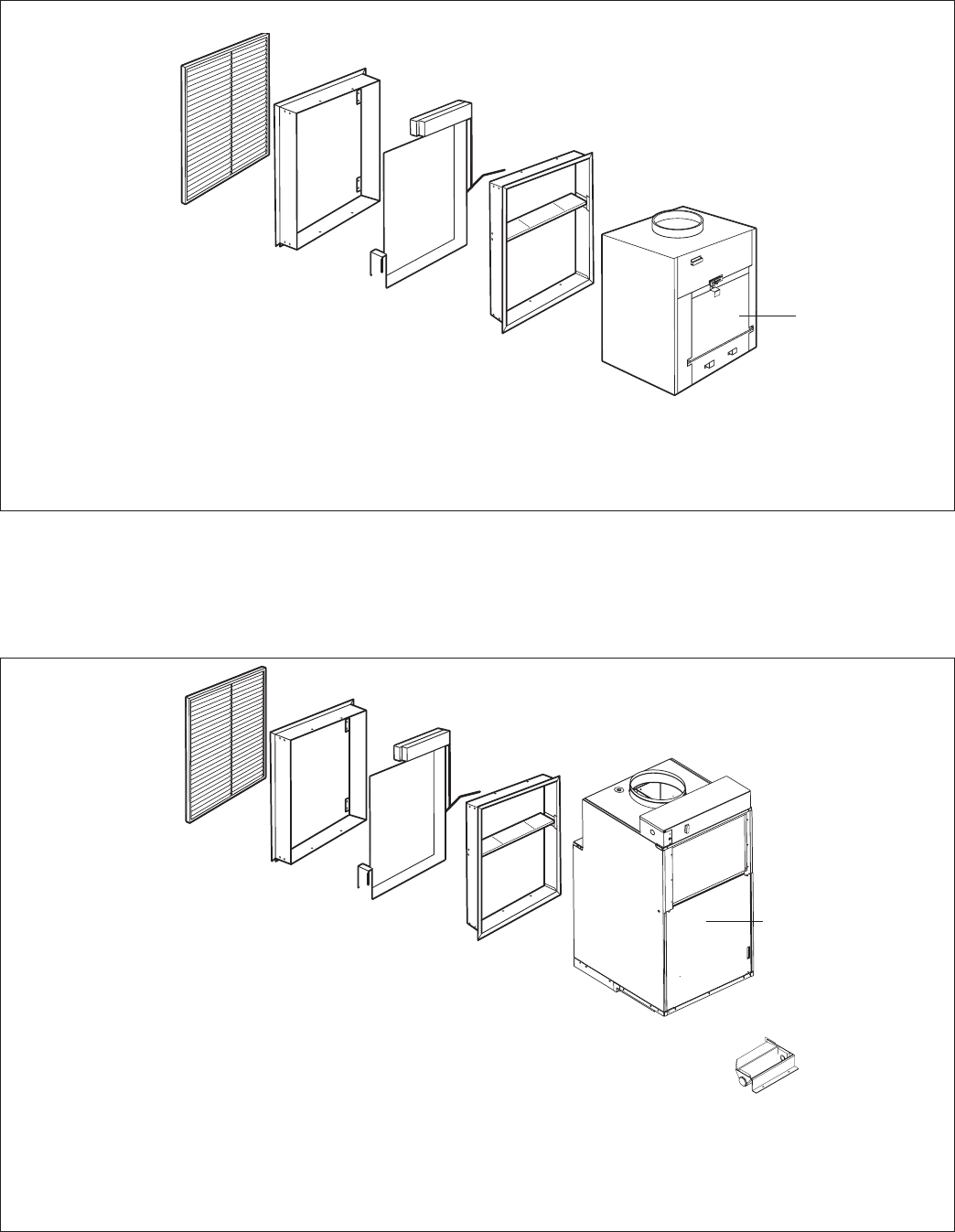

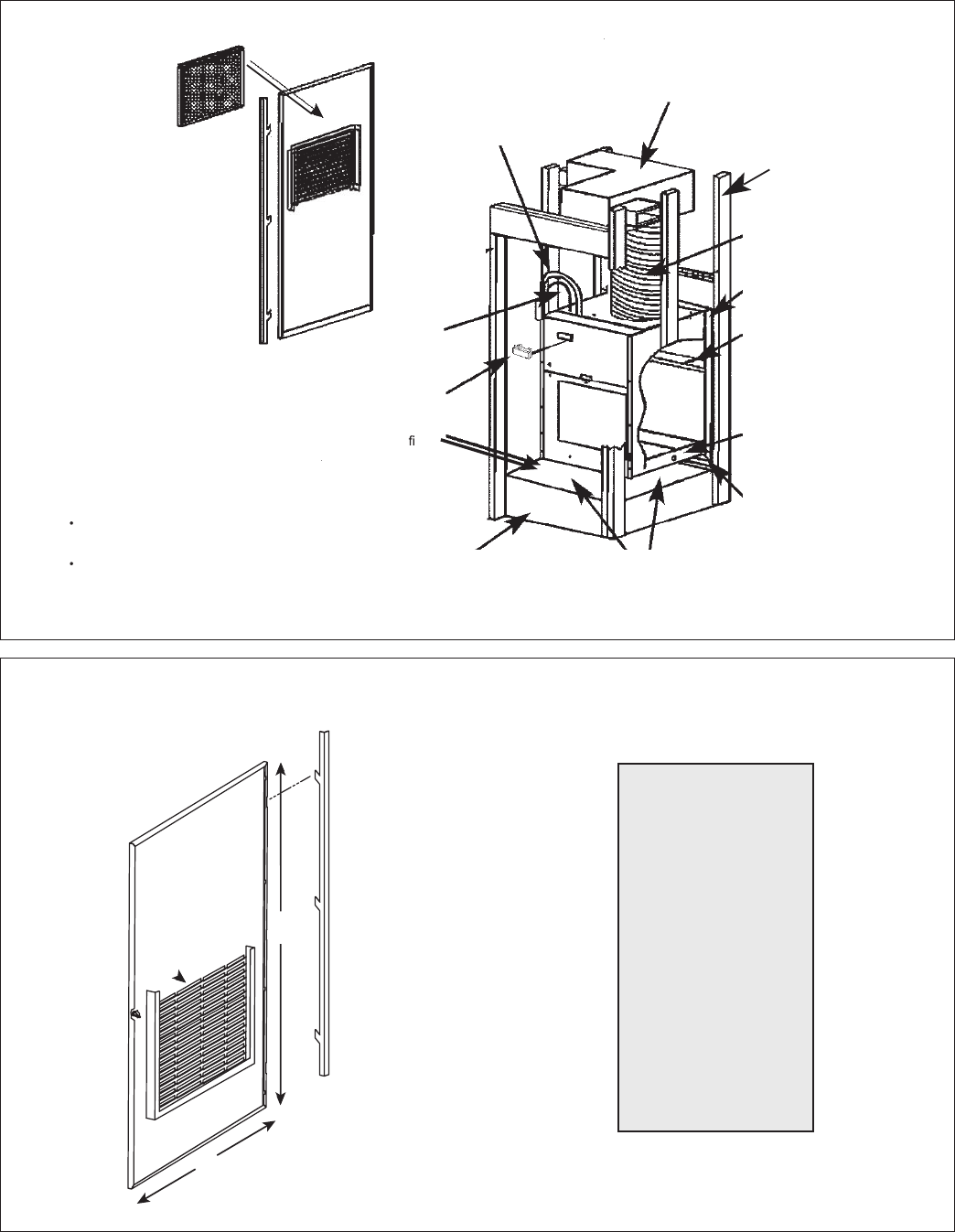

INSTALLATION OVERVIEW

VHA09 & VHA12

Louver VPAL2/VPSC2

(Sold separately)

Exterior/

Outside Wall

Part B

Inside

Wall Plenum

Unit

Part A

Outside

Wall Plenum

Applicable Models

VHA09K

VHA09R

VHA12K

VHA12R

Filter (14” x 20”)

Louver VPAL2/VPSC2

(Sold separately)

Exterior/

Outside Wall

Part B

Inside

Wall Plenum

Part A

Outside

Wall Plenum

Large Chassis Unit

(Unit height 47”)

VPDP2 drain pan required

(Sold & shipped

separately)

Filter (14” x 20”)

VPAWP1-8 = 5 1/2" - 8" D x 24 1/8" W x 30 3/8" H

VPAWP1-14 = 8" - 14" D x 24 1/8" W x 30 3/8" H

INSTALLATION OVERVIEW

VHA18

VPAWP1-8 = 5 1/2" - 8" D x 24 1/8" W x 30 3/8" H

VPAWP1-14 = 8" - 14" D x 24 1/8" W x 30 3/8" H

Applicable Models

VHA18K

VHA18R

11

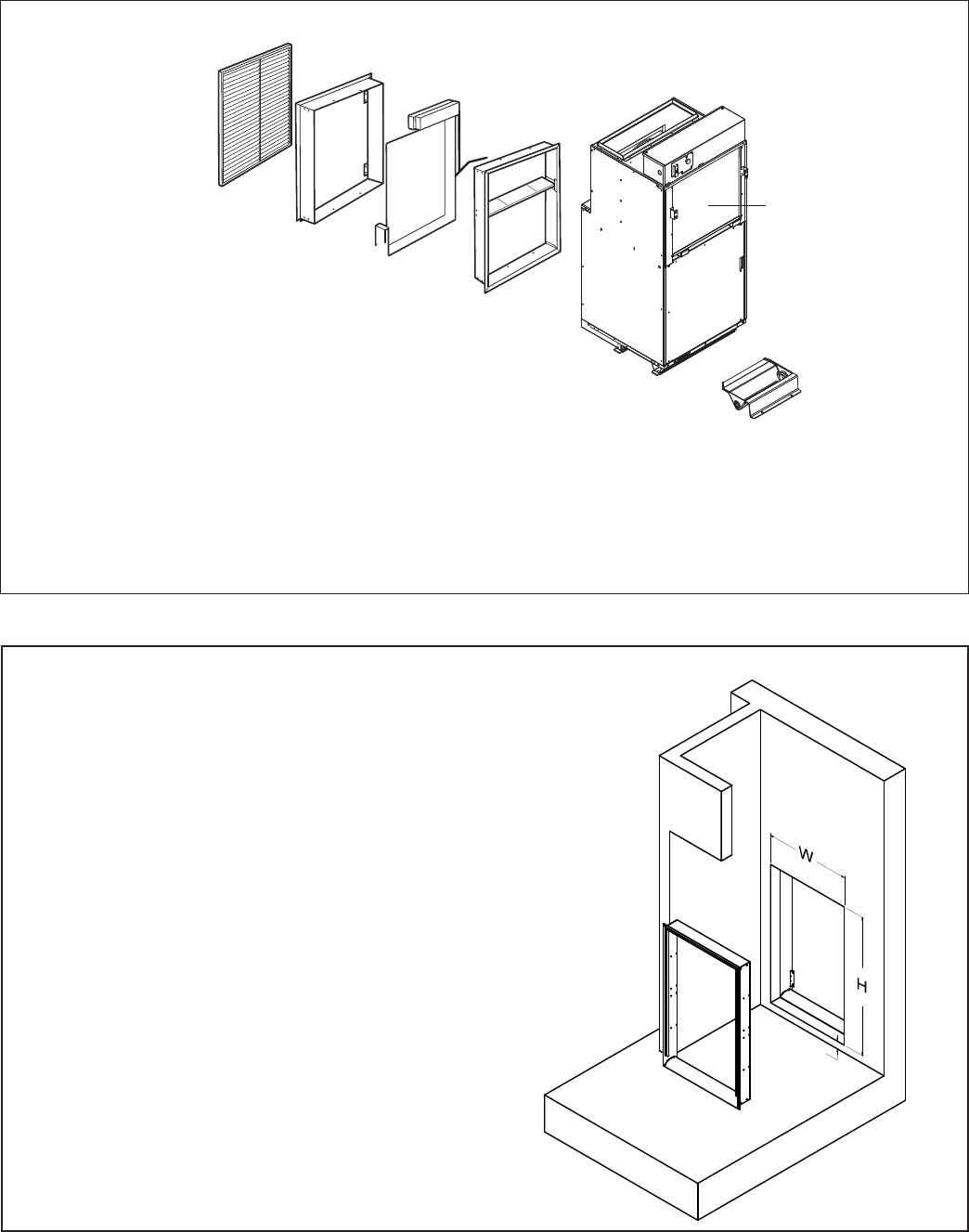

INSTALLATION OVERVIEW

VHA24

Louver VPAL2/VPSC2

(Sold separately)

Exterior/

Outside Wall

Part B

Inside

Wall Plenum

Unit

Part A

Outside

Wall Plenum

Applicable Models

VHA24K

VHA24R

Filter (18” x 20”)

VPAWP1-8 = 5 1/2" - 8" D x 24 1/8" W x 30 3/8" H

VPAWP1-14 = 8" - 14" D x 24 1/8" W x 30 3/8" H

VPDP2 drain pan required

(Sold & shipped

separately)

3/4”

NOTE: The distance between the rough

opening and the nished oor/platform

must be 3/4”.

INSTALL HEIGHT

12

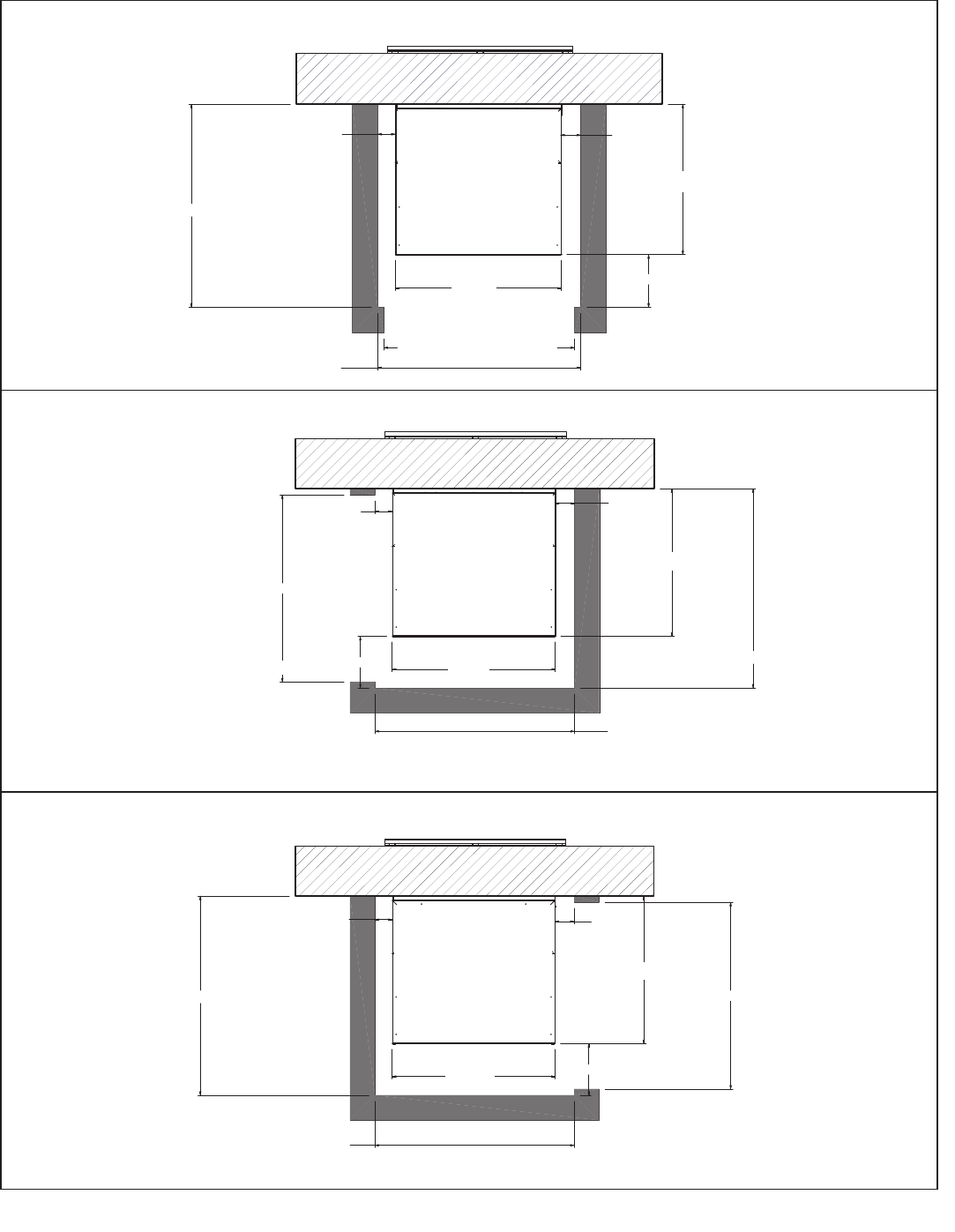

INSTALLATION OVERVIEW

CLOSET ORIENTATIONS AND DIMENSIONS

)URQW,QVWDOODWLRQ7RS9LHZ

/HIW,QVWDOODWLRQ7RS9LHZ

5LJKW,QVWDOODWLRQ7RS9LHZ

3

23 1/8"

23 1/8"

23 1/8"

23 1/8"

23 1/8"

23 1/8"

31 1/8"

31 1/8"

30 5/8"

30 5/8"

3"

26 1/8"

29 1/8"

27"

27"

27"

13

TYPICAL UTILITY CLOSET

58"

29"

Cutout

Dimensions:

27" W x 55-

3

⁄

4

" H

Hinge on left

Side of door

Same indoor (closet) wall cut

out for all models

VPRG4/VPRG4R

Access Panel and

Return Air Filter Grille

Electrical

Connection

Rigid Ductwork

Flexible Ductwork

Exterior Wall

V PAW P1 - 8 /1-14

Wall Plenum

Plenum Divider

3/4" FPT Drain

Connection

Optional, field-supplied platform

Please reference orientation details

for clearance requirements

Power

Disconnect

Wiring

Chassis installs

2

3

/

8

" into Plenum

V PAW P1-8/1-14 WallPlenum cut-out

dimensions 24

5

/

8

" wide x 30

7

/

8

" high.

VPRG4 Access Panel cutout dimensions:

27"wideby55

3

/

4

" high.

Recommended eld

installed drain pan

25" x 20" Filter

(Field Supplied)

Thermostat

Chassis shown in closet on

optional platform

Access Panel with

Return Air Grille

VPRG4/VPRG4R

Filter Size: 25” x 20”

Field Supplied

14

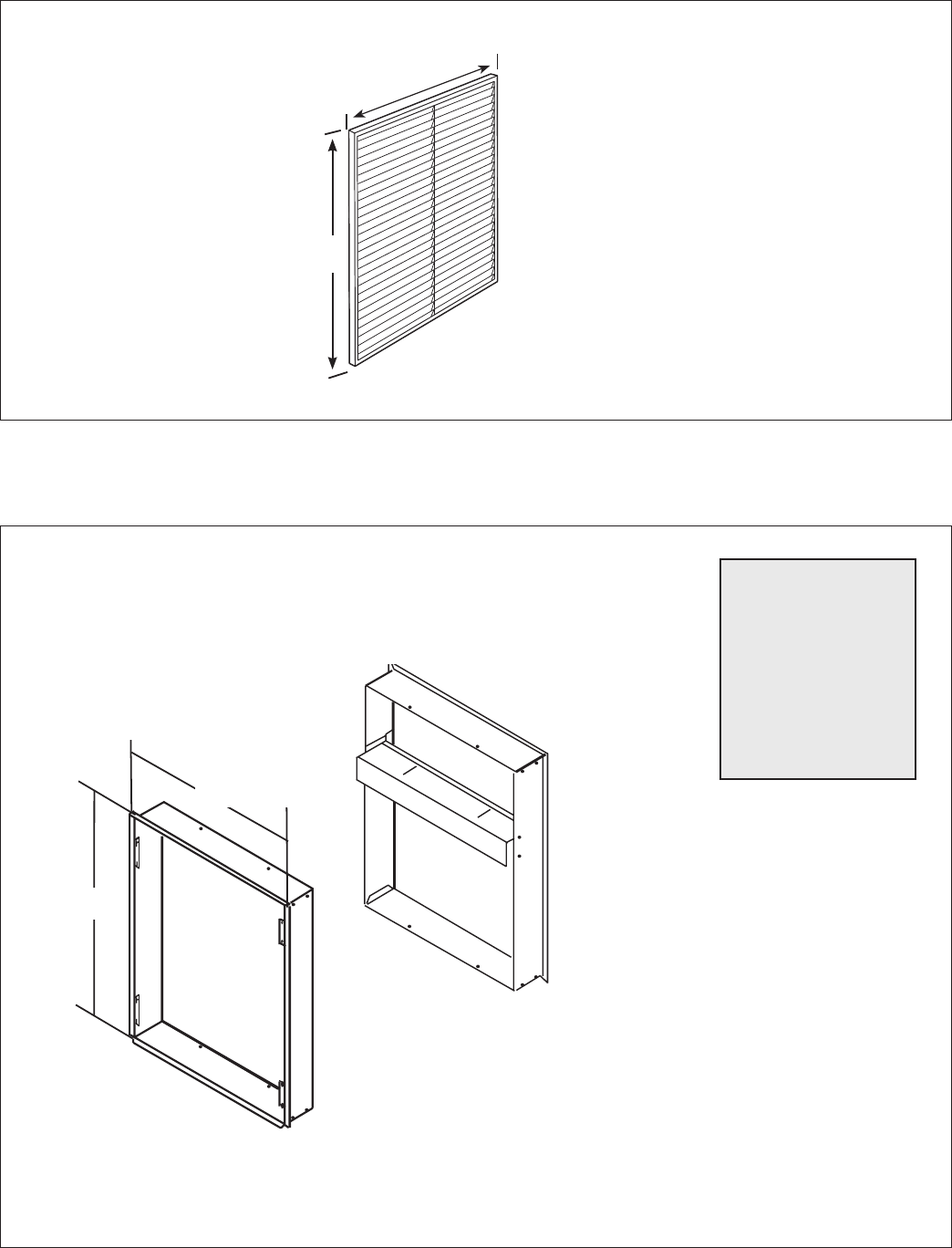

ACCESSORIES DIMENSIONS

VPAL2 / VPSC2 Louver

VPAWP1-8 Wall Plenum

Cutout

Dimensions:

24-

5

/

8

" W x 30-

7

⁄

8

”H

Architectural Louver

VPAL2/VPSC2

25-

9

/

16

”

31-

1

/

16

”

Wall Plenum

VPAWP1-8 - telescopes from 5-

1

/

2

” to 8”

VPAWP1-14 - telescopes from 8” to 14”

A

B

30-

3

/

8

"

24-

1

/

8

"

15

Application and Accessories (All models)

• The use of a Friedrich wall plenum is required for instal-

lation. Plenum opening is

3

/

4

" above the oor (VPAWP1-8 /

VPAWP1-14).

• Return air is accommodated with a return air lter attached

to the unit or through the use of a return air lter grille.

(VPRG4/VPRG4R).

• Exterior louvers are available in anodized aluminum (VPAL2)

or in custom painted colors (VPSC2).

• Unit is controlled by a remote wall-mounted thermostat.

Friedrich model WRT2 wireless digital thermostat, RT7

wired digital thermostat, RT7P wired programmable ther-

mostat, or EMRT2/EMWRT2 Energy Management Stats are

recommended.

• Central desk control ready.

Typical Closet Arrangement

Cutaway of a typical closet shown with Vert-I-Pak

®

chassis

installed in the wall sleeve. The unit has the thermostat, eld

wiring, internal drain and ex duct attached. VPRG4 return air

lter holder and access panel are shown below.

The closet access panel may be installed in the front (as shown

below) or to the left or right side of the unit. All three installation

options will allow easy access to the unit for removal and

replacement.

Application and Installation

Installation Guidelines

• Chassis is to be installed against an exterior wall. Wall

cutout dimensions will be 24 5/8" w x 30 7/8" h.

• Closet should allow for a minimum of three inches on three

sides of the unit for return air, drain connections and change

outs.

• Minimum recommended access door rough-in measure-

ments 27" wide by 55

3

/

4

" high (for VPRG4/VPRG4R).

• Friedrich recommends the use of a platform between 24"

and 36" above the oor, for ease of installation and ser vice-

ability.

• Duct outlet designed for external static pressures up to .3"

on 9,000 and 12,000, Btu models

• Duct outlet designed for external static pressures up to .4"

on 18,000 and 24,000, Btu models

• Wall plenum allows chassis to be inserted 2

3

/

8

" into ple-

num, thereby minimizing closet dimensions.

• Quick connect drain coupling ships standard to make

installation and removal easier.

Application and Accessories (18K & 24K Models)

• 18K & 24K utilize a drain pan (VPDP2) that can be installed

prior to chassis for simplied installation and removal.

16

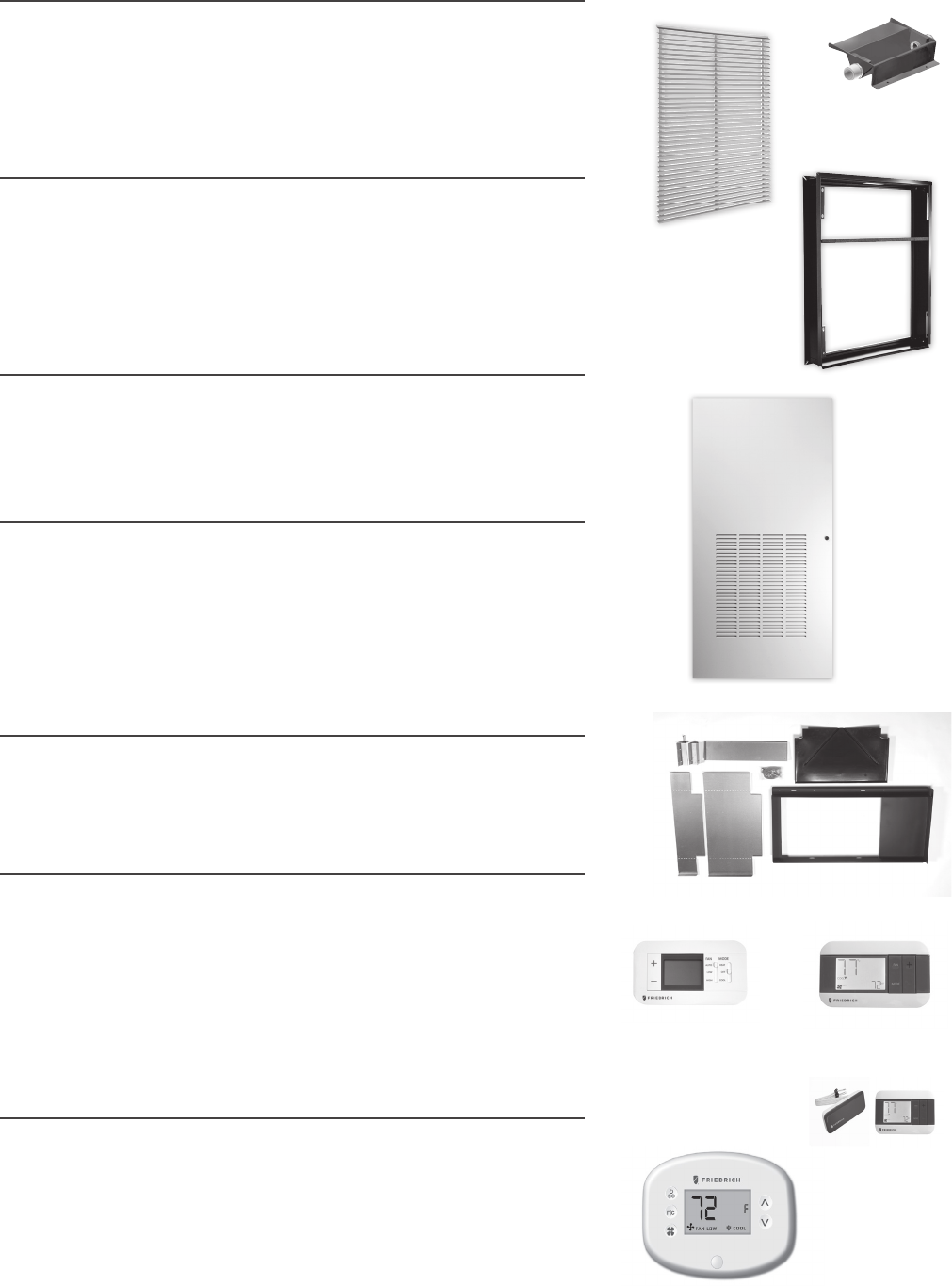

REQUIRED ACCESSORIES

ARCHITECTURAL LOUVER

VPAL2 and VPSC2

Extruded aluminum grille that attaches to the outdoor section of the wall

plenum. Takes in fresh air and returns condensed air. VPSC2 can be ordered in

custom colors.

DIMENSIONS: 25 9/16" W x 31 1/16" H

WALL PLENUM

VPAWP1-8, VPAWP1-14

Two-part sleeve that telescopes in and out. Sits inside the exterior wall

penetration.

VPAWP1-8 telescopes from 5 1/2”–8”

VPAWP1-14 telescopes from 8”–14”

DIMENSIONS: 24 1/8” W x 30 3/8” H

CUTOUT DIMENSIONS: 24 5/8” W x 30 7/8” H

DRAIN PAN

VPDP2

Required for all VHA18 and VHA24 models. May be installed prior to chassis for easy

installation/removal.

RETURN AIR GRILLE/ACCESS PANEL

VPRG4 / VPRG4R

Hinged panel allows access to unit and return air lter.

A eld-supplied lter (25” x 20”) should be mounted on the inside grille. Panel

can be mounted with return air openings high or low on the door for optimum

sound attenuation.

DIMENSIONS: 29” W x 58” H

CUTOUT DIMENSIONS: 27” W x 55 3/4” H

FIRST COMPANY SLEEVE ADAPTER

VPASA1

Single piece, welded adapter allows retrot into existing First Company SPXR-

series single package vertical unit wall sleeve and louver. Easy connection to

Friedrich small chassis VERT-I-PAK.

SINGLE STAGE THERMOSTATS

RT7P

Wired, single stage, wall-mounted programmable thermostat has two fan

speeds and backlight. Controls Friedrich VERT-I-PAK.

RT7

Wired, single stage, wall-mounted digital thermostat with two fan speeds and

backlight for control of Friedrich VERT-I-PAK.

WRT2

Wireless, single stage, wall-mounted digital thermostat with two fan speeds

and backlight for control of Friedrich VERT-I-PAK.

ENERGY MANAGEMENT THERMOSTATS

EMRT2/EMWRT2

Wired/Wireless thermostat with occupancy sensor.

EMOCT EMRAF EMROS

Online connection kit. Remote access fee. Remote Occupancy Sensor

EMRTS EMRDS EMCWP EMRWOS

Remote Temperature Sensor Door Switch Wall-Plate Wireless Occ. Sensor

RT7

EMRT2, EMWRT2

VPAL2

VPAWP1-8/14

VPRG4/R

VPASA1

VPDP2

RT7

WRT2

OPTIONAL ACCESSORIES

17

All units shall be factory assembled, piped, wired and fully

charged with R-410A. All units shall be certied in accordance

with ARI Standard 390 for Single Packaged Vertical Air Condi-

tioners and Heat Pumps. Units shall be ETL listed and carry a

ETL label. All units shall be factory run-tested to check opera-

tion and be manufactured by Friedrich or equivalent.

The basic unit shall not exceed 23

1

/

8

" wide x 23

1

/

8

" deep. Overall

height of the unit from the bottom of the isolators to the top of

the duct collar shall not exceed 32 ¼" for models up to 12,000

Btu , 47 ¼" for 18,000 Btu models, and 51 1/4" for 24,000 Btu

models. The unit shall be designed so that the unit will insert

into a factory supplied wall plenum 2

3

/

8

" to minimize room intru-

sion. Factory supplied wall plenums shall allow for installation

through walls from 4 ½" – 14" in thickness. Wall plenums will be

adjustable to minimize installation clearances. Unit shall draw

in ambient air through upper portion of an outside architectural

louver measuring 25

9

/

16

" wide x 31

1

/

16

" high and shall exhaust

heated air out through the lower portion of the louver. The unit

shall be secured to the architectural louver by means of a two

part, weather-resistant wall plenum. The unit shall be capable

of left, right or straight-in installations into mechanical closet

without eld modications.

REFRIGERATION SYSTEM – The refrigeration system shall be her-

metically sealed and consist of a rotary compressor that is exter-

nally mounted on vibration isolators no smaller than 1 ¾" dia. x 1 ½"

high; condenser and evaporator coils constructed of copper tubes

and aluminum plate ns; and capillaries as expansion devices. Unit

shall have a fan slinger ring to increase efciency and condensate

disposal. A primary condensate removal system consisting of ¾"

FTP ttings on multiple locations shall exist. A secondar y over ow

from the primary drain pan shall expel water to the outside of the

building through the wall plenum and louver in the event that the

primary drain line clogs.

AIR HANDLING SECTION – The condenser fan shall be driven

by a single BLDC fan motor for models up to 12,000 Btu. 18,000

and 24,000 Btu models shall utilize a separate motor for both

the indoor and outdoor air sections. Airow shall be directed

ver tically up through a standard 10" ex duct starter collar and

into exible or rigid ducts to be distributed into the conditioned

area on models up to 18,000 Btu. Starter collar shall have both

crimped edge to ease ex duct installation and a waistline to

prevent duct from loosening.

The chassis shall have a built-in damper capable of providing

up to 60 CFM of fresh air into the conditioned area. A ne mesh

screen shall lter the incoming fresh air. The damper can be

controlled by a slide lever located on the front of the unit.

CONTROLS – The unit shall be factory equipped with terminal

strip for connection to a standard 24-volt single-stage heat/

cool thermostat. A transformer shall be included and fac-

tory wired to work with Friedrich branded or factory approved

devices.. Low voltage inputs will include: C (common), R (24V

power), Y (cooling), G (fan), W (heat) and B (reversing valve on

VHA heat pumps only).The unit shall be hard-wired and have

a quick-disconnect to disable power for control box service.

An emergency heat override switch must be available to allow

operation of the resistance heater in the event of a compressor

failure on heat pump models.

GENERAL CONSTRUCTION – The unit shall be constructed of

18-gauge galvanized zinc-coated steel. The unit shall feature

½" foil backed insulation for sound and thermal efciency.

The wall plenum (required factory accessory) shall be shipped

separately and constructed of 20-gauge galvanized zinc-coated

steel; pretreated with zinc-phosphate and sealed with a chro-

mate rinse, then powder-coated for maximum coverage and

protection. The plenum shall be black in color for minimal

visibility of unit from exterior of building. The plenum shall be

shipped with a protective weatherboard for use prior to nal

installation of the louver and chassis.

The architectural louver (required factory accessory) shall

be shipped separately and fabricated from extruded anodized

aluminum with louvers in the horizontal plane.

The unit shall include vibration isolators mounted under the

chassis and a nonrigid plenum-to-chassis connection to isolate

vibrations to the building.

The unit shall have a plastic fan, fan shroud and drain pan and

aluminum outdoor coil endplates for corrosion protection and to

help prevent rust on the side of the building below the outdoor

louver.

The unit shall be shipped with return air lter brackets and a

14" x 20" or 18" x 20" lter afxed directly on to the unit chassis.

Optional return air grilles and access panels shall be available

as factory accessories for installation in the wall or door of the

mechanical closet.

CORROSION PROTECTION - The unit shall feature corrosion

-resistant materials and nish to help prevent deterioration.

The outdoor coil shall have Diamonblue advanced corrosion pro-

tection consisting of hydrophilic-coated ns to prolong the life of

the coil in all applications including seacoast protection.

ACCESSORY ACCESS PANEL - An optional factory-supplied access

panel shall be available to provide access to the unit and adequate

return air. The panel shall feature a lter holder to accept a eld

supplied 25” x 20” x 1” lter. Kit shall contain a hinge bracket for

mounting the door with the return air openings high or low on the

door for optimal sound attenuation.

WARRANTY – The warranty is one year on all parts and labor

and 5 years on the sealed system, parts and labor, including

compressor, indoor and outdoor coils and refrigerant tubing.

HVAC Engineering Specications

A-Series Vertical Packaged Air Conditioners & Heat Pumps

Cooling: 9300 – 22500 Btu

Heating: 8300 – 19500 Btu (Heat Pump)

8500 – 34130 Btu (Electric Heat)

Friedrich Models: VHA – Heat Pump with electric heat

18

Vert-I-Pak

®

Single Package Heat Pumps

MODEL IDENTIFICATION GUIDE

Electric Heater Size

A Series

25 = 2.5 KW

34 = 3.4 KW

50 = 5.0 KW

75 = 7.5 KW*

10 = 10.0KW**

MODEL NUMBER V H A 09 K 34 RT P

Marketing Model

Options

RT = Standard Remote Operation

Voltage

K = 208/230V-1Ph-60Hz

R = 265V-1Ph-60Hz

Nominal Capacity

A Series (Btu)

09 = 9,000 18 = 18,000

12 = 12,000 24 = 24,000

Series

VHA=Vertical Heat Pump

* ONLY AVAILABLE ON THE 18 & 24 K/R MODELS

**ONLY AVAILABLE ON THE 24 K/R MODELS

PURCHASER P.O. # DATE

PROJECT LOCATION

ENGINEER ARCHITECT

SUBMITTED BY FOR APPROVAL FOR REFERENCE

ITEM PLAN DESIGNATION QUANTITY COOLING Btu VOLTAGE FRIEDRICH MODEL

A-SERIES ACCESSORIES (Wall Plenum and Outdoor Louver are required)

VPAWP1-8 Adjustable Wall Plenum (5 ½"- 8") Qty

VPAWP1-14 Adjustable Wall Plenum (8"-14") Qty

VPAL2 Architectural Louver Qty

VPSC2 Architectural Louver (color matched) Qty

VPASA1 Sleeve adapter for exact t in existing

First Company SPXR-series with small chas-

sis VPAK

Qty

VPRG4 Return Air Grille/Access Panel Qty

VPRG4R Access Panel (Right In-swing) Qty

VPDP2 Drain Pan for VHA18 & VHA24 Qty

RT7 Wired Digital Wall Thermostat Qty

RT7P Wired Programmable Wall Thermostat Qty

WRT2 Wireless Digital Wall Thermostat Qty

EMRT2 Wired Thermostat with Occupancy Sensor Qty

EMWRT2 Wireless Thermostat with Occupancy

Sensor

Qty

EMOCT Online Connection Kit Qty

EMRAF Remote Access Fee Qty

Qty

Qty

VERT-I-PAK

®

SUBMITTAL_2022

19

SAVE THIS CERTIFICATE. It gives you specic rights. You may also have other rights which may vary from state to state and province to province.

In the event that your unit needs servicing, contact your nearest authorized service center. If you do not know the nearest service center, ask the com-

pany that installed your unit or contact use - see address and telephone number above. To obtain service and/or warranty parts replacement, you must

notify an authorized FRIEDRICH Air Conditioning Co. service center, distributor, dealer, or contractor of any defect within the applicable warranty period.

When requesting service: please have the model and serial number from your unit readily available.

Unless specied otherwise herein, the following applies:

FRIEDRICH VERT-I-PAK A SERIES HEAT PUMPS & AIR CONDITIONERS

LIMITED WARRANTY - FIRST YEAR (Twelve (12) months from the date of installation). Any part found to be defective in the material or workman-

ship will be repaired or replaced free of charge by our authorized service center during the normal working hours; and

LIMITED WARRANTY - SECOND THROUGH FIFTH YEAR (Sixty (60) months from the date of installation). ON THE SEALED REFRIGERATION

SYSTEM. Any part of the sealed refrigeration system that is defective in material or workmanship will be repaired or replaced free of charge (excluding

freight charges) by our authorized service center during normal working hours. The sealed refrigeration system consists of the compressor, metering

device, evaporator, condenser, reversing valve, check valve, and the interconnecting tubing.

These warranties apply only while the unit remains at the original site and only to units installed inside the continental United States, Alaska,

Hawaii, Puerto Rico, Mexico and Canada. The warranty applies only if the unit is installed and operated in accordance with the printed instruc-

tions and in compliance with applicable local installation and building codes and good trade practices. For international warranty information,

contact the Friedrich Air Conditioning Company - International Division.

Any defective part to be replaced must be made available to FRIEDRICH in exchange for the replacement part. Reasonable proof must be presented to

establish the date of install, otherwise the beginning date of this certicate will be considered to be our shipment date plus sixty days. Replacement parts

can be new or re-manufactured. Replacement parts and labor are only warranted for any unused portion of the unit’s warranty.

We will not be responsible for and the user will pay for:

1. Service calls to:

A) Instruct on unit operation. B) Replace fuses or correct wiring. C) Clean or replace air lters. D) Remove the unit from

its installed location when not accessible for service required. E) Correct improper installations.

2. Parts or labor provided by anyone other than an authorized service center.

3. Damage caused by:

A) Accident, abuse, negligence, misuse, riot, re ood or acts of God. B) Operating the unit where there is a corrosive atmosphere containing

chlorine, uorine, or any damaging chemicals (other than in a normal living environment). C) Unauthorized alteration or repair of the unit,

which in turn aects its stability or performance. D) Failing to provide proper maintenance and service. E) Using and incorrect power source. F)

Faulty installation or application of the unit. G) Operation of the unit during construction.

We shall not be liable for any incidental, consequential, or special damages or expenses in connection with any use or failure of this unit. We

have not made and do not make any representation or warranty of tness for a particular use or purpose and there is no implied condition of

tness for a particular use or purpose. We make no expressed warranties except as stated in this certication No one is authorized to change

this certicate or to create for us any other obligation or liability in connection with this unit. Any implied warranties shall last for one year

after the original purchase date. Some states and provinces do not allow limitations on how long an implied warranty or condition lasts, so the above

limitation or exclusions may not apply to you. The provisions of this warranty are in addition to and not a modication of or subtraction from the statutory

warranties and other rights and remedies provided by law.

Performance of Friedrich’s Warranty obligation is limited to one of the following methods:

1. Repair of the unit

2. A refund to the customer for the prorated value of the unit based upon the remaining warranty period of the unit.

3. Providing a replacement unit of equal value

The method of fulllment of the warranty obligation is at the sole discretion of Friedrich Air Conditioning.

In case of any questions regarding the provisions of this warranty, the English version will govern.

(11-19)

VERT-I-PAK

®

SINGLE PACKAGE VERTICAL AIR CONDITIONERS

LIMITED WARRANTY

Friedrich Air Conditioning Company

10001 Reunion Place, Suite 500

San Antonio, Tx 78216

800.541.6645

www.friedrich.com

Friedrich Air Conditioning Co. l 10001 Reunion Place, Suite 500 l San Antonio, TX 78216 l 877.599.5665 l www.friedrich.com

VPAK PP FEB-2023 9521 4200_13