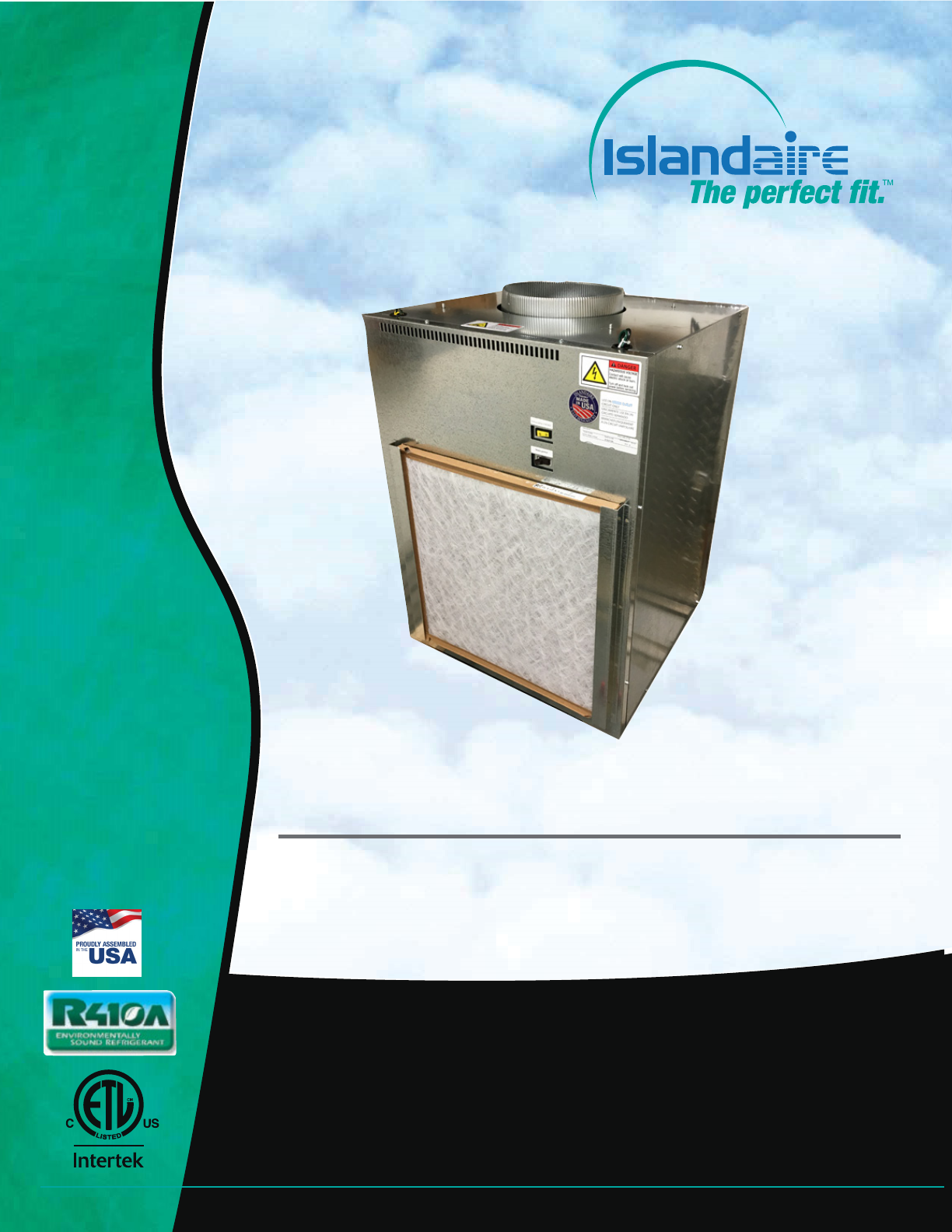

EZ Series VP & EZ Series VR (DR. VTAC option)

Perfect t for Replacing Existing GE 8500 & 7500 Series

Friedrich Vertical and for New Construction Projects

Engineering Manual

MANUFACTURER OF QUALITY AIR CONDITIONING AND HEATING PRODUCTS

6140278 Rev. J 03/19/18

Manufacturer of Quality Air Conditioning and Heating Products • www.islandaire.com • sales@islandaire.com • (800)-886-2759

2

Table of Contents

Islandaire reserves the right to make changes in design and construction at any time without notice.

INSTALLATION INSTRUCTIONS CASE

& CHASSIS ....................................................................21

Unit including case and chassis .....................................21

INSTALLATION INSTRUCTIONS DRAINS ............. 22

Drain Connection(s) .....................................................22

INSTALLATION INSTRUCTIONS POWER

CORD, DUCT .............................................................. 23

Unit Power Connection ................................................. 23

Voltage Measurements ...................................................23

Connect the Top Duct ................................................... 23

INSTALLATION INSTRUCTIONS THERMOSTAT .24

Remote Wall Mounted ermostat ............................... 24

Wireless Wall Mounted ermostat ..............................24

Remote ermostat Interface ........................................25

INSTALLATION INSTRUCTIONS INTERIOR

GRILLE .......................................................................... 26

Interior Return Air Grille .............................................. 26

WIRING DIAGRAMS ....................................................27

SYSTEM CONTROLS AND MANAGEMENT .............. 29

USER INTERFACES ...................................................... 29

Wall ermostats ........................................................... 29

Front Desk Control ........................................................ 29

Controls Logic ............................................................... 30

Room Freeze Prevention ............................................... 30

High Temperature Compressor Protection .................. 30

Low Temperature Compressor Protection .................... 30

Diagnostic Soware .......................................................30

Custom Operation and Continual Room

Temperature Monitoring .............................................. 30

Operating Guidelines ....................................................31

MAIN CONTROL BOARD .......................................... 32

PERFORMANCE SPECIFICATIONS ...........................33

Vertical Packaged Terminal Cooling Unit With

Heat Pump Or Electric Heating ...................................33

TYPICAL WARRANTY ................................................. 36

EZ REPLACEMENT GUIDE ..........................................37

INTRODUCTION ..........................................................3

Our Company ................................................................ 3

e Perfect Fit ................................................................ 3

APPLICATIONS .............................................................4

New Construction ..........................................................4

Advantages For New Construction ............................... 4

Retrot/Replacement .................................................... 4

Application Considerations ..........................................5

Undersizing ....................................................................5

Oversizing ...................................................................... 5

Air Inltration ............................................................... 5

Guaranteed Quality ....................................................... 5

Indoor Air Quality - DR.VTAC .....................................5

PRODUCT OVERVIEW ................................................ 6

Quiet Operation ............................................................ 6

Durable Construction ...................................................6

Corrosion Protection ..................................................... 6

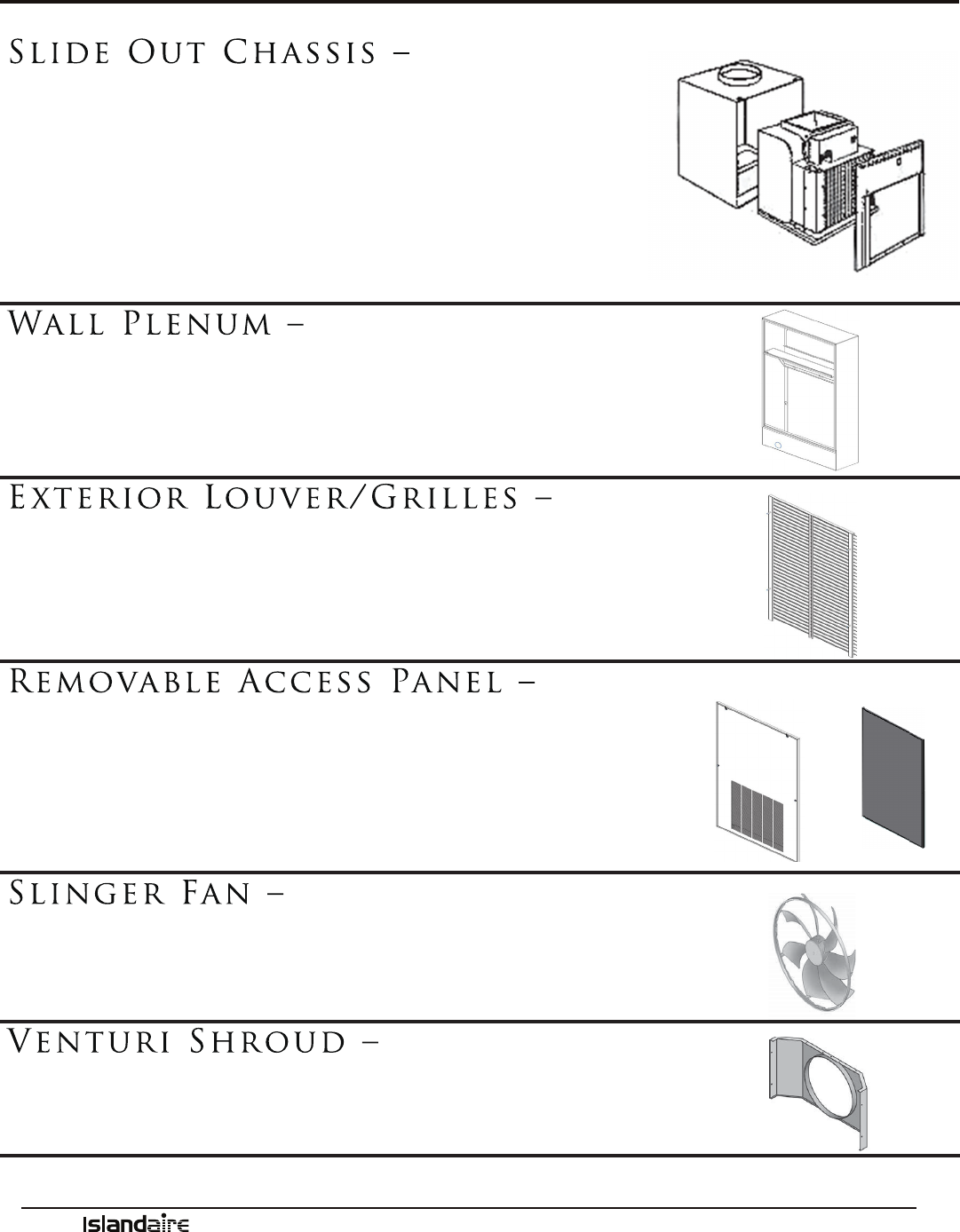

CHASSIS FEATURES AND BENEFITS ........................ 7

Slide Out Chassis – ........................................................ 7

Wall Plenum – ................................................................7

Exterior Louver/Grilles – .............................................. 7

Removable Access Panel – .............................................7

Slinger Fan – ..................................................................7

Venturi Shroud – ........................................................... 7

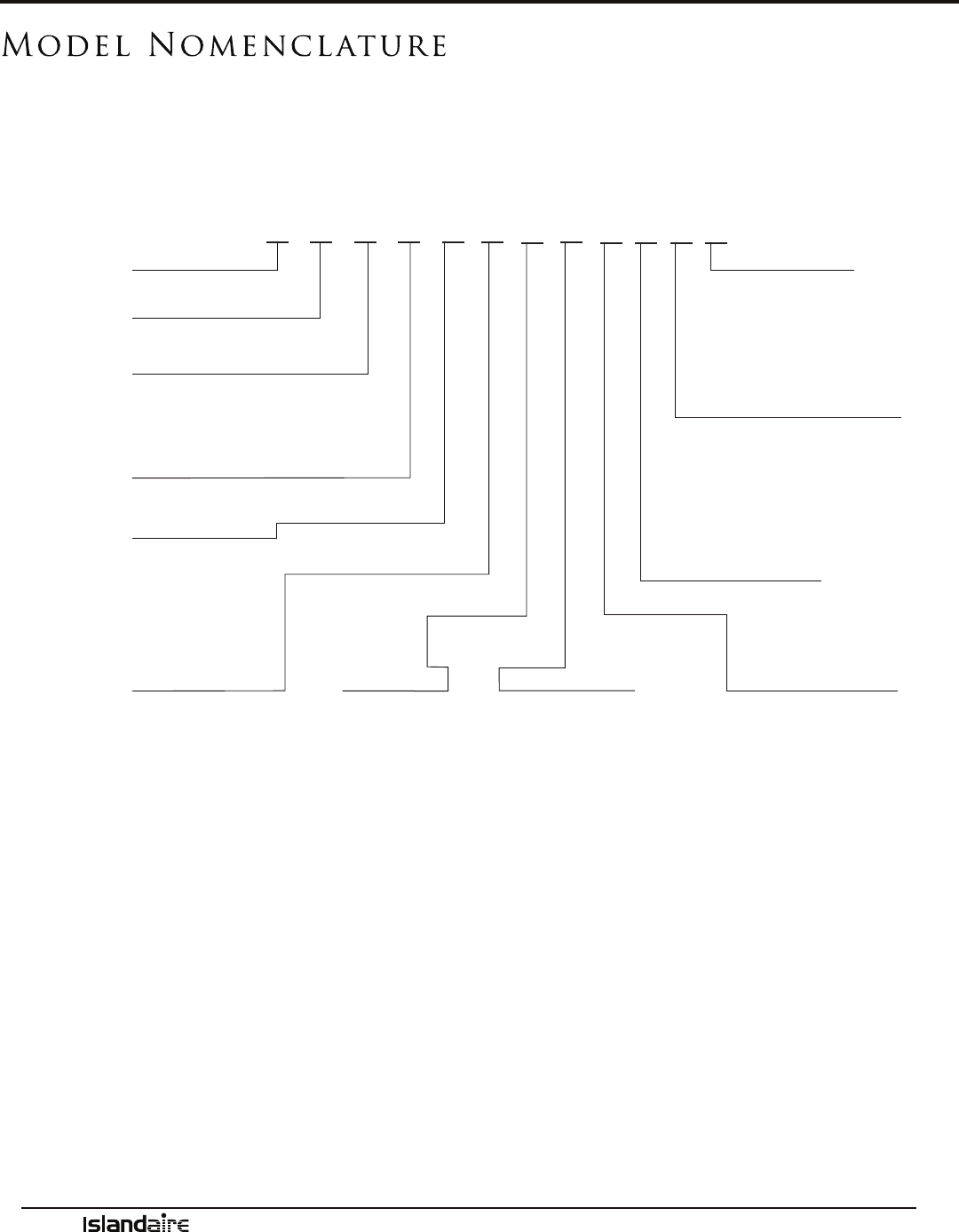

EZ SERIES VP DATA ...................................................... 8

Model Nomenclature ..................................................... 8

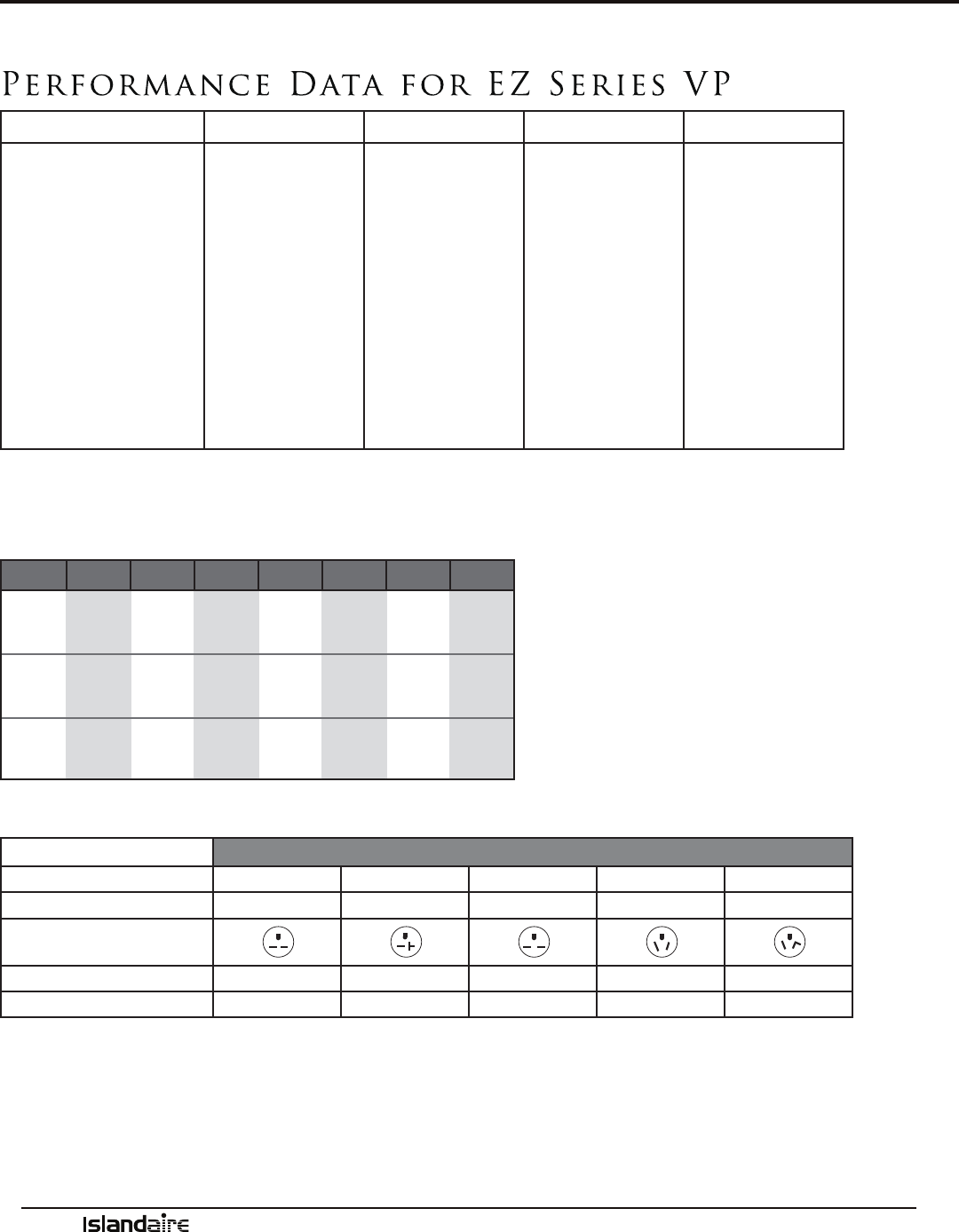

Performance Data for EZ Series VP .............................. 9

Heating options ............................................................. 9

Electrical ........................................................................9

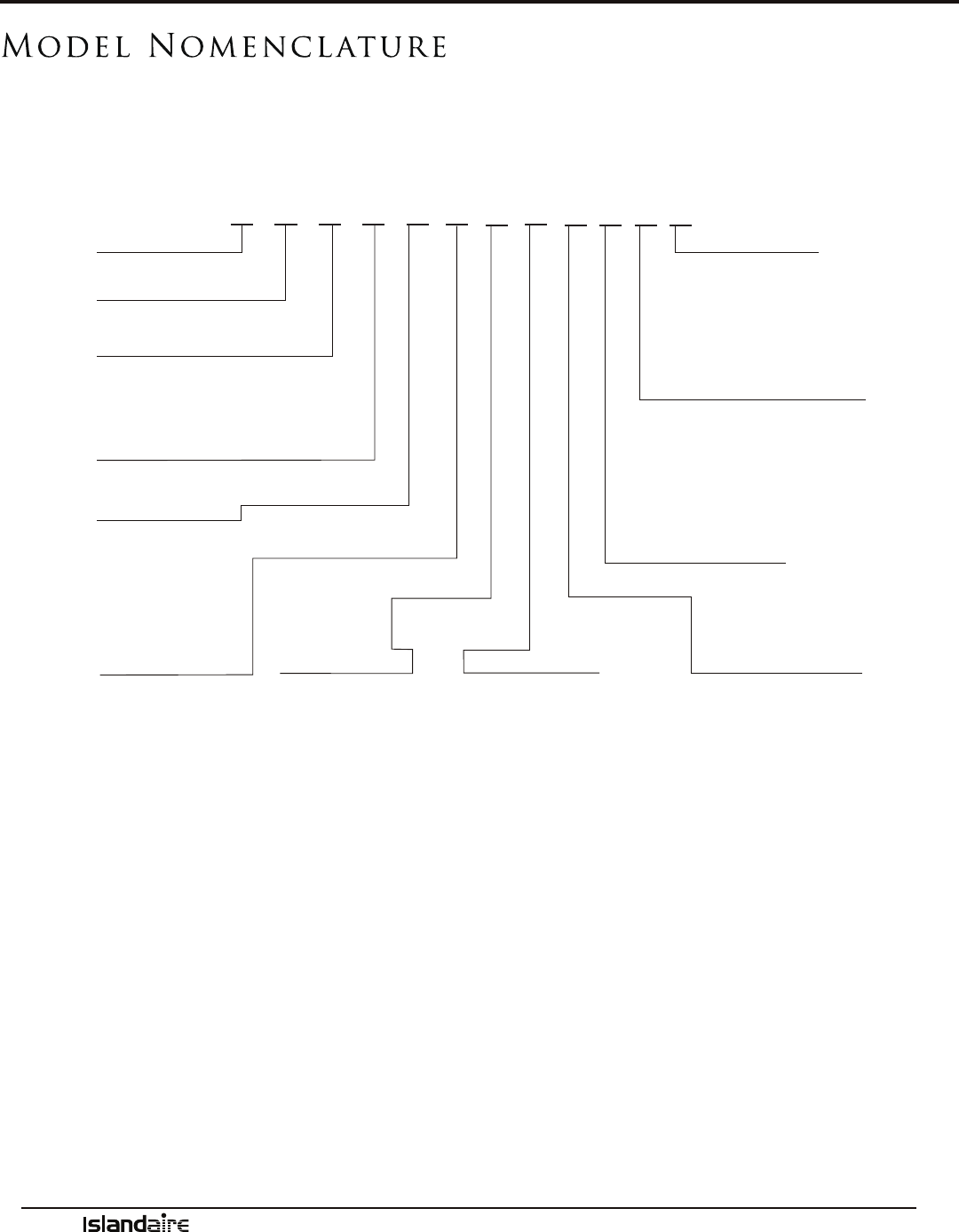

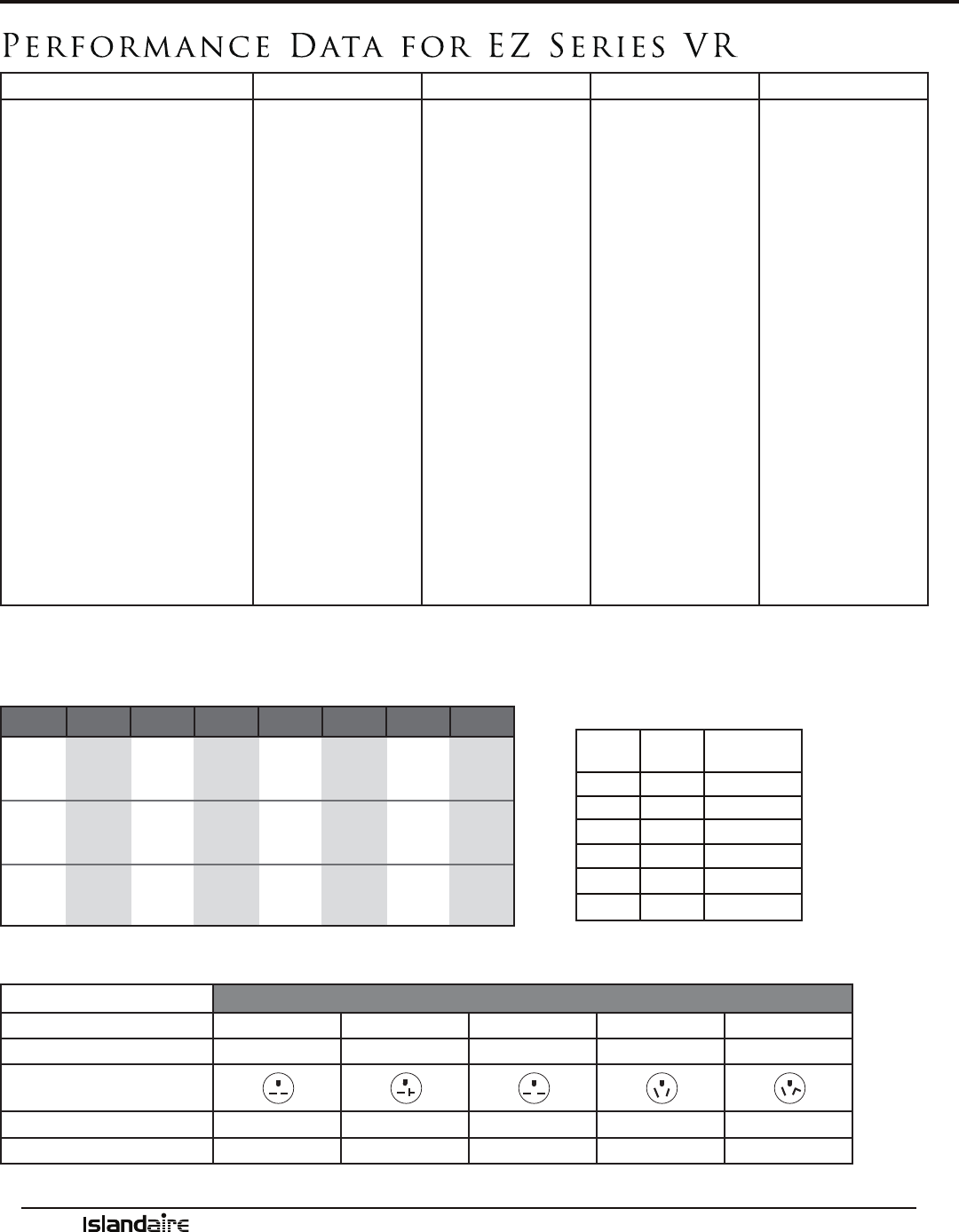

EZ SERIES VR DATA ...................................................... 10

Model Nomenclature ..................................................... 10

Performance Data for EZ Series VR ..............................11

Heating options ............................................................. 11

Electrical ........................................................................11

PRODUCT INFORMATION .........................................12

Heat Pump Features ...................................................... 13

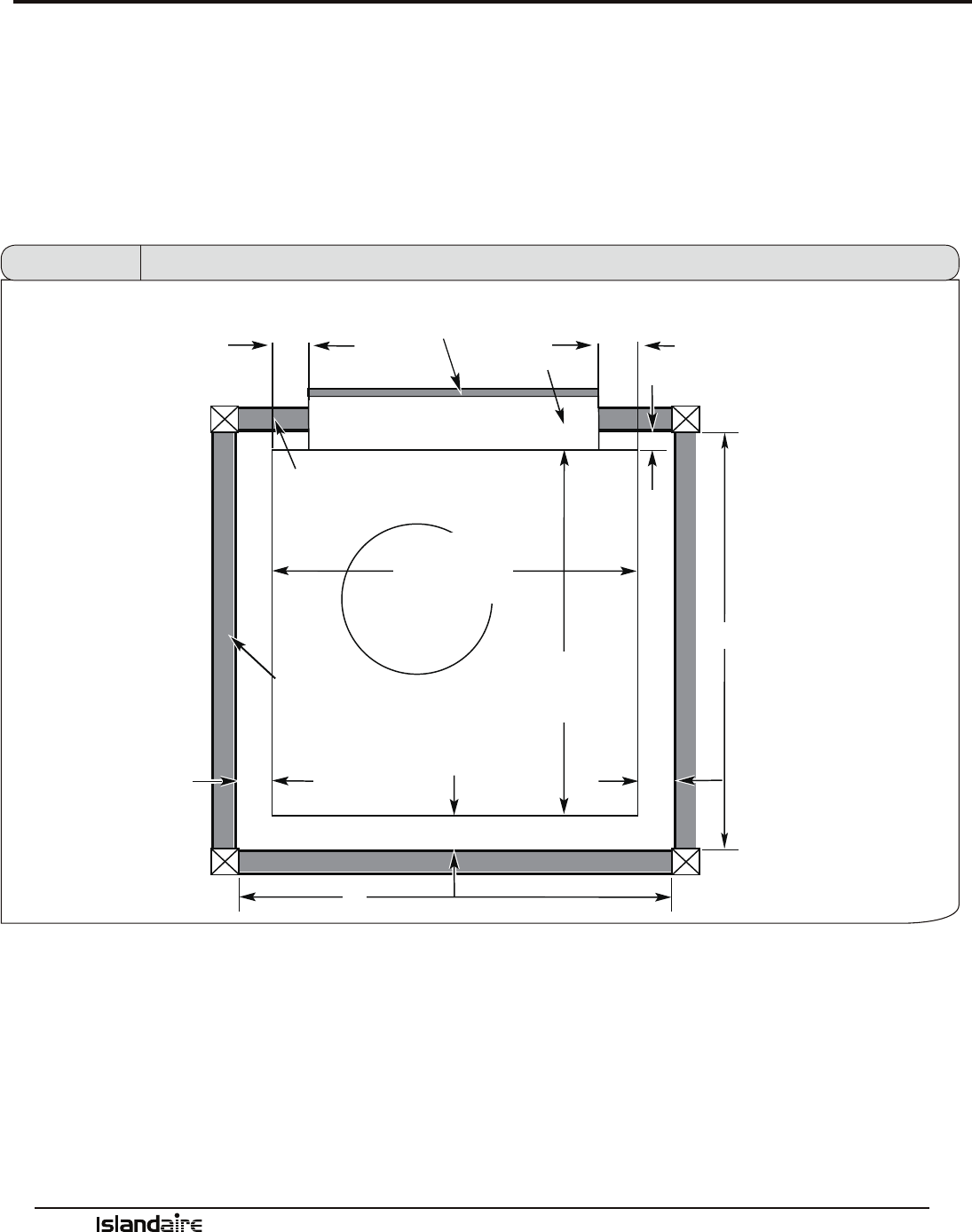

DIMENSIONAL DRAWINGS ........................................ 14

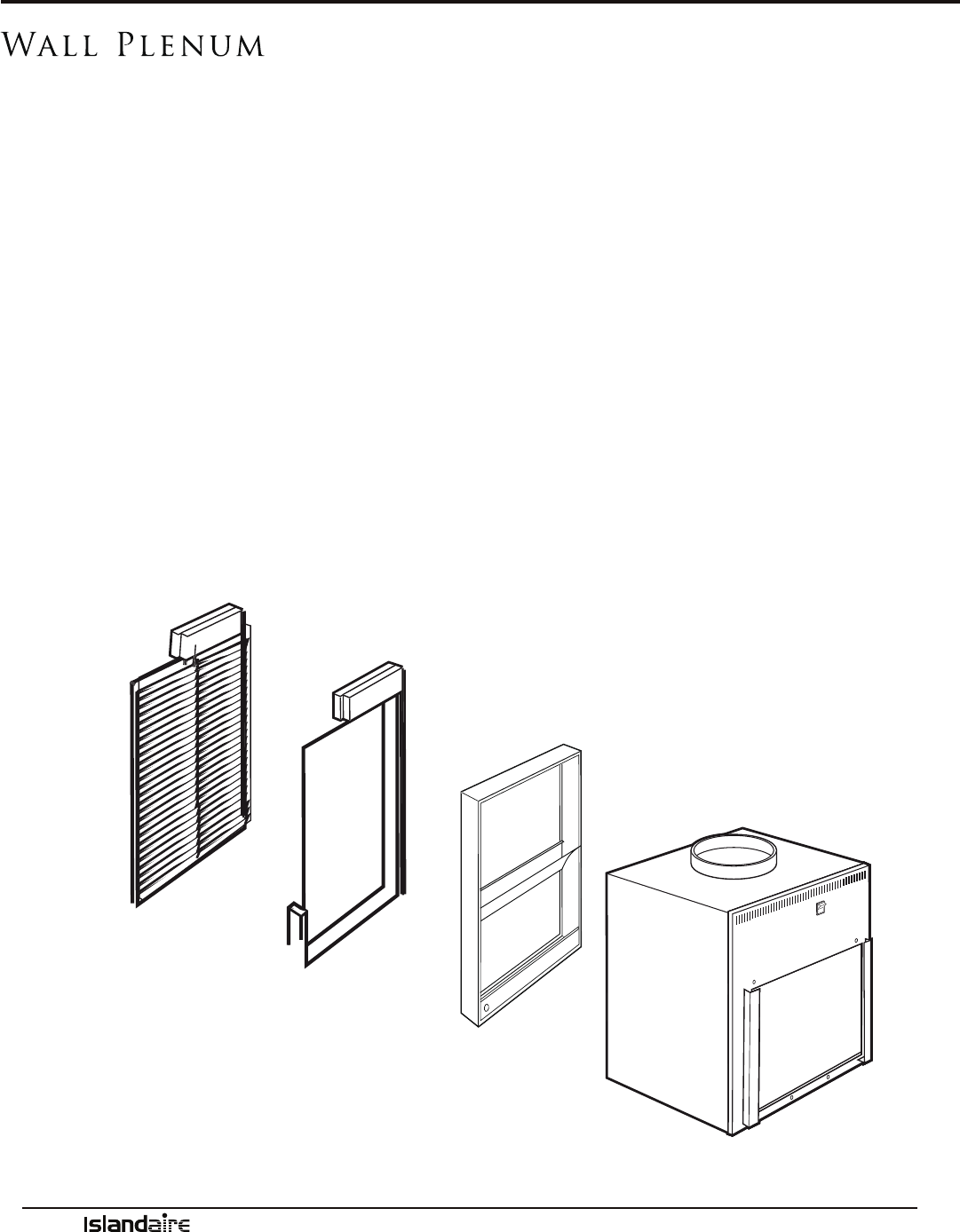

INSTALLATION INSTRUCTIONS WALL PLENUM 17

Wall Plenum ...................................................................17

INSTALLATION INSTRUCTIONS EXTERIOR

GRILLE .......................................................................... 18

Standard exterior (Rear) Grille ..................................... 18

Architectural Exterior (Rear) Grille ............................. 19

INSTALLATION INSTRUCTIONS BASE

PLATFORM ................................................................... 20

Base Platform Construction .......................................... 20

Manufacturer of Quality Air Conditioning and Heating Products • www.islandaire.com • sales@islandaire.com • (800)-886-2759

3

Our Company

Islandaire is the fastest growing specialty air conditioning and heat-

ing manufacturer in the country. Founded in 1992 by Robert Hansen,

it has grown into a multi-million dollar company in just a few short

years. Islandaire builds a full complement of high quality thru-the-

wall replacement air conditioners and heat pumps, water source heat

pumps, and gas units in East Setauket, New York. Each model ts per-

fectly into the existing original wall case assembly, thereby saving both

time and money during installations.

Our Engineering, Production, Sales and Customer Service depart-

ments have been fully integrated to provide the maximum degree

of user satisfaction. We at Islandaire feel that this team approach to

manufacturing produces a superior overall product and assures a larger

degree of exibility in design and production scheduling to meet tight

prototyping or construction timetables.

The Perfect Fit

ru-wall air conditioners were developed in the late 1950’s. Over

the next forty years many companies engineered, manufactured and

installed a variety of dierent units throughout the United States and

Canada. Today, a number of these companies are no longer in business

or have discontinued their line of thru-wall air conditioners and no

longer carry replacement parts.

Islandaire oers replacement air conditioners and heat pumps that are

interchangeable with units no longer available from the original manu-

facturer. Our units are engineered to t perfectly within the existing

wall case, thereby reducing installation time and expense. ey are

manufactured at our modern 75,000 square foot plant on Long Island

in New York.

ank you for considering our products,

e Islandaire Team

Introduction

Manufacturer of Quality Air Conditioning and Heating Products • www.islandaire.com • sales@islandaire.com • (800)-886-2759

4

Applications

ADVANTAGES FOR NEW CONSTRUCTION

• Lower Operating Costs and Reliable Comfort

for the Occupant

• Design Flexibility For e Architect/Engineer

• Super-quiet performance, indoors and out

• No bulky duct system needed

• No separate equipment room

• No water towers or additional cooling equip-

ment

• Optional architectural grille to permit custom

exterior appearance

Islandaire helps lower utility costs with energy e-

cient units that exceed industry standards. Energy

savings are achieved in both heating and cooling

environments through ecient mechanical design

and onboard electronic logic. Separate indoor and

outdoor fans provide lower operating costs. Energy

management capability is built into the unit’s stan-

dard digital controls.

ese units may also qualify for electrical power

company rebates. Consult your local utility provider

for rebate opportunities.

Retrofit/

Replacement

Islandaire VTAC units are engineered to t per-

fectly within existing GE wall cases, thereby reduc-

ing installation time and expense. ere is no time

wasted on redesigning an existing wall opening or

removing an old wall case. Just slide the old chassis

out and replace with a new one from Islandaire.

Our EZ Quick slide-out chassis eases installation

into the wall case. Rapid servicing reduces down-

time; the complete chassis can be replaced in min-

utes without disrupting other occupants.

e EZVP and EZVR Series vertical terminal air

conditioning (VTAC) units are designed and manu-

factured for new construction or the replacement of

units in an existing building. Our VTAC units pro-

vide year-round comfort control for hotels, motels,

apartments, dormitories, shops, nursing homes,

assisted living centers, satellite oces, room addi-

tions and other applications that require economical

heating and cooling.

e product is designed for individually-zoned,

comfort-controlled heating and cooling. We oer

our cooling chassis to operate with cooling only or

electric heat. e design standards, heavy duty con-

struction and the focus on indoor noise reduction

has established our product as the premier unit of

the future. Individually controlled VTAC units are

ideal for rooms that are not occupied, such as during

vacancies, holidays, weekends or nights. Individual

units permit tenants to choose their own degree of

comfort and operating economy.

Temperature and fan settings are controlled via wall

thermostat. In addition, all units have the ex-

ibility of working with controls that integrate with

an energy management system. Whether you are

designing a new structure or replacing VTAC units

in an existing building, Islandaire will meet your

needs.

New Construction

e Islandaire VTAC unit is designed to meet the

needs of the architect, engineer, and contractor. For

unit installation, Islandaire’s expert support network

will assist in all applicable aspects of the construc-

tion project, from preparing a budget to start-up.

Manufacturer of Quality Air Conditioning and Heating Products • www.islandaire.com • sales@islandaire.com • (800)-886-2759

5

Applications (Cont.)

Guaranteed Quality

Each Islandaire unit is designed to operate quietly

and eciently and is backed by the best warranty

program available. Standard warranty is for one

year parts and labor including ve year compressor

part only warranty, or two year parts only including

ve year compressor part only warranty.

Whether it is an exact replacement unit or a new

construction project, Islandaire is the smart choice

for all your air conditioning and heating needs.

Indoor Air Quality -

DR.VTAC

In addition to an already quiet unit, we have

developed an indoor air quality option called the

DR.VTAC.

DR.VTAC is a two-stage system. e primary stage

conditions room air and tempers the air to accept-

able air quality levels. e secondary stage brings in

conditioned outside air at a rate of up to 75 CFM, to

compensate for toilet exhaust and room occupancy,

and continuously pressurizes the room. e sec-

ondary stage is initiated by an outdoor humidistat

that allows the unit to condition the incoming fresh

air to about 55% RH. e system can be calibrated

to run at higher outdoor RH levels, but the recom-

mended maximum set point is 55% outdoor RH.

When outdoor RH levels are above the set point, the

secondary compressor is initiated and conditions

make up air.

e secondary fan continuously runs allowing fresh,

conditioned, make-up air at a rate of up to 75 CFM

(leaving coil CFM) to enter the room. e unit is

manufactured in accordance to AHRI, UL, CSA

standards for the primary side and AHAM and UL

standards for the secondary side.

Application

Considerations

It is important for air conditioning systems to

be properly sized for each application in order to

achieve desired temperature and humidity levels. It

is strongly recommended that a professional engi-

neer match the VTAC units with the building struc-

ture and regional climate.

e following application considerations are all

important in choosing the proper VTAC system for

the building structure.

UNDERSIZING

If a VTAC unit is undersized (cooling capacity is

less than required capacity for the specic applica-

tion), the unit will not be able to cool the space

down to the desired temperature during very hot

days, causing excessive power consumption.

OVERSIZING

If a VTAC unit is oversized (cooling capacity is

greater than required capacity for the specic appli-

cation), the unit will cool the space down to the

desired temperature too quickly, creating a cool yet

excessively humid space.

AIR INFILTRATION

Excessive air inltration can intensify problems

associated with undersizing or oversizing a VTAC

unit. is can be the cause of insucient cooling,

dehumidication, or heating. Sources of air inltra-

tion include vents, gaps around windows and doors,

and improperly sealed oors, ceiling or wall joints.

Manufacturer of Quality Air Conditioning and Heating Products • www.islandaire.com • sales@islandaire.com • (800)-886-2759

6

Product Overview

Corrosion

Protection

All Islandaire VTAC units have special corrosion

protection that can help dramatically extend the life

of the unit. Listed below are just some of the com-

ponents that feature corrosion protection:

• Wall Case - e entire wall case is constructed

of 18-gauge galvanized steel.

• Base Pan - e base pan is constructed of

18-gauge galvanized steel with powder coat

paint nish to protect it from the elements.

• Condenser Fan Blade - Constructed of strong

engineered plastic that has excellent ame-

resistance and dimensional stability over a wide

range of service temperatures.

• Condenser Fan Motor - Specially coated by the

manufacturer to resist corrosion.

• Compressor - Protectively-coated exterior to

enhance equipment life and performance.

• Outdoor Louver - Made of aluminum, etched

and anodized for maximum corrosion protec-

tion. Available in various architectural styles.

Can be painted in a wide choice of colors.

Quiet Operation

e VTAC unit provides whisper quiet operation

while delivering maximum airow required for

proper air circulation. Separate indoor and out-

door fan motors further reduce operating sound

levels and costs.

e heavy gauge construction of the chassis and

cabinet minimizes vibration for quieter operation.

Vibration isolators on the rotary compressor keep

it running smoothly and quietly. e unit bulk-

head is fully insulated to decrease outdoor sound

transmission.

Durable

Construction

• Islandaire VTAC units are built with durable

quality components designed for continuous

operation in all environments.

• Our wall cases are constructed of 18-gauge

thick galvanized steel for maximum durability.

• e outdoor fan motor is totally enclosed,

preventing damage from moisture and debris

introduced by extreme weather conditions.

Both indoor and outdoor fan motors are per-

manently lubricated for extended life.

• Electrical components are located on the

indoor side of the wall protecting them from

driving rain and humidity.

• e compressor is a reliable, high-eciency

design rotary compressor. It is hermetically

sealed and built for continuous operation.

Manufacturer of Quality Air Conditioning and Heating Products • www.islandaire.com • sales@islandaire.com • (800)-886-2759

7

Slide Out Chassis –

• Slide-out chassis makes installation simple

• All components are readily accessible to service personnel

• On-board diagnostic soware and display help diagnose potential

problems

• Designed to replace older units with minimal modication

• Isolated rotary compressor design for continuous ecient, reliable

and quiet operation

See page 21 for chassis installation instructions

Wall Plenum –

• Heavy 18 gauge steel with powder paint coating for maximum

scratch, dent and corrosion resistance

• Optional wall depths of 6”, 8”, 10”, 12”, and 15” available

See page 17 for wall plenum installation instructions

Exterior Louver/Grilles –

• Architectural extruded aluminum grille

• Custom colors available (Ask for our color chart sheet)

• Recessed available

See page 18 for exterior grille installation instructions

Removable Access Panel –

• Made from durable, powder-coated metal that won’t rust, resists

scratches and is easy to clean

• Quick removal ensures shorter installation time and faster service

calls

• Easy access to removable lters

• Optional Sound-Reduction Grille for quieter operation

Slinger Fan –

• Curved fan blades increase airow across the outside coil

• Creates a quiet operating environment outside of building

• Slinger ring eciently removes condensate and increases cooling

Venturi Shroud –

• Works with the fan to maximize air ow and increase eciency

• Removes easily for quick access when cleaning the condenser coil

Chassis Features and Benefits

Manufacturer of Quality Air Conditioning and Heating Products • www.islandaire.com • sales@islandaire.com • (800)-886-2759

8

EZ Series VP Data

Model Nomenclature

Please review the nomenclature/model number

breakdown below for the EZ Series VP options.

Units are available in four cooling BTUh capaci-

ties: 9,000; 12,000; 15,000; 18,000

Voltage options are: 208/230V or 277V

Control choices include multiple-wired, wall-

mounted heating/cooling thermostats and a wireless

wall thermostat, with occupancy sensor control.

FEATURES: ACCESSORIES:

•18 gauge galvanized, powder-coat

painted wall plenum

•Motion sensor/door switch

capable

•Superior temperature control

•Dehumidication of room air

•Wall thermostat required

•Compressor freeze protection

•Self diagnosis

•Random Auto Re-start

•Compressor time delay

•Front desk control capable

•Room side freeze protection

•Motorized fresh air damper

•Power disconnect

•High pressure cutout

•Wired remote thermostat

•Wireless remote thermostat

•Energy Management ermostat

•I.R. motion sensor

•Door switch

•Access Panel (louvered, non-

louvered, and sound-reduction

types)

•Return Air Grille

OPTIONS:

•Architectural Louver

COMPONENT

EZ - Cooling Chassis

MODEL TYPE

VP - Islandaire Vertical Unit

COOLING CAPACITY

09 - 9,000 BTU

12 - 12,000 BTU

15 - 15,000 BTU

18 - 18,000 BTU

VOLTAGE / LINE CORD

2 - 230V 20 Amps

3 - 230V 30 Amps

4 - 230V Junction Box

7 - 277 V 20 Amps

8 - 277 V Junction Box

9 - 230V 15 Amps

F - 277V 30 Amps

HEATING OPTIONS

A - None, Cooling Only

B - 2.5 KW Electric Heat

C - 3.6 KW Electric Heat

E - 5.0 KW Electric Heat*

*5.0 KW heat available on

15 & 18 kBTU units only

ROOM CONTROLS

1- None

N - Standard Electronic Control Remote

Thermostat

FUNCTIONAL OPTIONS

B- Motorized Fresh Air Damper

POWER MANAGEMENT OPTIONS

A- None

C- Energy Mgt. N/O

D- Energy Mgt. N/C

IDENTITY CODE

0 - Special

5 - Standard

RETURN DISCHARGE OPTIONS

4 - Front Return/Top Discharge

EZ VP 12 A 2 C 1 N 4 5 A B

HYDRONIC OPTIONS

SYSTEM TYPE

A - Standard Chassis (R410A)

B - Heat Pump (R410A)

Manufacturer of Quality Air Conditioning and Heating Products • www.islandaire.com • sales@islandaire.com • (800)-886-2759

9

EZ Series VP Data (Cont.)

Performance Data for EZ Series VP

EZ09 EZ12 EZ15 EZ18

VOLTS 208-230 265-277 208-230 265-277 208-230 265-277 208-230 265-277

COOLING BTUH 8900 8900 11700 11700 14800 14800 17500 17500

COOLING LATENT BTUH 2225 2225 2925 2925 3700 3700 4375 4375

COOLING SENSIBLE BTUH 6675 6675 8775 8775 11100 11100 13125 13125

AMPS 3.87 3.21 5.09 4.22 6.43 5.34 7.61 6.32

COOLING WATTS 890 890 1170 1170 1480 1480 1750 1750

EER 10 10 10 10 10 10 10 10

CFM HIGH SP 0.1” 424 424 482 482 532 532 565 565

CFM LOW SP 0.1” 370 370 421 421 475 475 525 525

HEATING BTUH 8400 8400 10900 10900 13400 13400 15500 15500

HEATING WATTS 820 820 1065 1065 1309 1309 1514 1514

COP 3 3 3 3 3 3 3 3

Heating capacities specied in accordance with ANSI/AHRI standard 390 at conditions of 47 °F DB/43 °F WB outdoor and 70 °F DB/60 °F WB indoor. Wattage, amperage, COP, EER listings include compressor,

evaporator motor and condenser fan motor. Cooling capacities specied in accordance with ANSI/AHRI standard 390 at conditions of 95 °F DB/75 °F WB outdoor and 80 °F/67 °F WB indoor.

HEATING OPTIONS

Heating

Option

Voltage (1) Wattage B.T.U.s (2) Amps (3) MCA (4) MOP (Amps) Power Cord

B

208

230

277

2,050

2,500

2,500

7,000

8,535

8,535

10.46

11.47

9.63

13.1

14.3

12.0

15

15

15

6-15

6-15

7-20

C

208

230

277

2,950

3,600

3,600

10,070

12,290

12,290

14.78

16.25

13.60

18.5

20.3

17.0

20

20

20

6-20

6-20

7-20

E

208

230

277

4,100

5,000

5,000

14,000

17,070

17,070

20.31

22.34

18.65

25.4

27.9

23.3

30

30

30

6-30

6-30

7-30

(1) Voltage is 60Hz, Single Phase, Alternating Current and R.M.S. (2) Heating Capacity (B.T.U./Hr.) based on indoor

blower motor and heating elements. (3) Amp values are a combination of indoor blower motor and heating elements.

ELECTRICAL

EZVR

LINE VOLTAGE 208/230 208/230 208/230 277 277

MAXIMUM AMPERAGE 12 16 24 16 24

WALL SOCKET CONFIGURATION

RECEPTACLE NUMBER NEMA 6-15R NEMA 6-20R NEMA 6-30R NEMA 7-20R NEMA 7-30R

ELECTRICAL HEAT OPTIONS 2.5 2.5 - 3.6 4.2 - 5.0 2.5 - 4.2 2.5 - 4.2

* All data is subject to change

Manufacturer of Quality Air Conditioning and Heating Products • www.islandaire.com • sales@islandaire.com • (800)-886-2759

10

Model Nomenclature

Please review the nomenclature/model number

breakdown below for the EZ Series VR options.

Units are available in four cooling BTUH capaci-

ties: 9,000; 12,000; 15,000; 18,000

EZ Series VR Data

Voltage options are: 208/230V or 277V

Control choices include multiple-wired, wall

mounted heating/cooling thermostats and a wireless

wall thermostat, with occupancy sensor control

HYDRONIC OPTIONS

MODEL TYPE

VR - DR. VTAC

VOLTAGE / LINE CORD

2 - 230V 20 Amps

3 - 230V 30 Amps

4 - 230V Junction Box

7 - 277 V 20 Amps

8 - 277 V Junction Box

9 - 230V 15 Amps

F - 277V 30 Amps

COMPONENT

EZ - Cooling Chassis

COOLING CAPACITY

09 - 9,000 BTU

12 - 12,000 BTU

15 - 15,000 BTU

18 - 18,000 BTU

SYSTEM TYPE

A- Standard Chassis (R410A)

B - Heat Pump (R410A)

HEATING OPTIONS

A - None, Cooling Only

B - 2.5 KW Electric Heat

C - 3.6 KW Electric Heat

E - 5.0 KW Electric Heat *

*5.0 KW heat available on

15 & 18 kBTU units only

ROOM CONTROLS

1- None

N - Standard Electronic Control

Remote Thermostat

FUNCTIONAL OPTIONS

A - None

B - Dehum-heater 250w

C - Dehum-heater 400w

POWER MANAGEMENT OPTIONS

A - None

P - Energy Mgt. N/O

T - Energy Mgt. N/C

IDENTITY CODE

0 - Special

5 - Standard

RETURN DISCHARGE OPTIONS

4 - Front Return/Top Discharge

EZ VR 12 A 2 C 1 N 4 5 A B

FEATURES: ACCESSORIES: LEED* POINTS ACHIEVED:

•18 gauge galvanized, powder-coat painted

wall plenum

•Up to 75 CFM Continuous

Conditioned fresh air

•Motion sensor/door switch capable

•Superior temperature control

•Dehumidication of room air

•Wall thermostat required

•Compressor freeze protection

•Self diagnosis

•Random Auto Re-start

•Compressor time delay

•Front desk control capable

•Room side freeze protection

•Power disconnect

•High pressure cutout

•Wired remote thermostat

•Wireless remote thermostat

•Energy Management ermostat

•I.R. motion sensor

•Door switch

•Access Panel (louvered, non-

louvered, and sound-reduction

types)

•Return Air Grille

OPTIONS:

•Electric heat add-on for the

DR.VTAC fresh air system for cold

climates

•Architectural Louver

1. Energy Ecient Design and compliance with ASHRAE

62.1 and ASHRAE 90.1

2. Indoor Environmental Quality with improved indoor air

quality (IAQ) through make up air

3. Innovation in design through the use of a “Make Up Air

VTAC”

4. Regional Design through the use of DR. VTAC in high-

humidity climates

5. Recycling/reusing DR.VTAC in secondary market where

the “rst costs” are prohibitive to owners

* LEADERSHIP IN ENERGY AND ENVIRONMENTAL

DESIGN (LEED)

Manufacturer of Quality Air Conditioning and Heating Products • www.islandaire.com • sales@islandaire.com • (800)-886-2759

11

EZ Series VR Data (Cont.)

Performance Data for EZ Series VR

EZ09 EZ12 EZ15 EZ18

VOLTS 208-230 265-277 208-230 265-277 208-230 265-277 208-230 265-277

COOLING BTUH 8900 8900 11700 11700 14800 14800 17500 17500

COOLING LATENT BTUH 2225 2225 2925 2925 3700 3700 4375 4375

COOLING SENSIBLE BTUH 6675 6675 8775 8775 11100 11100 13125 13125

AMPS 3.87 3.21 5.09 4.22 6.43 5.34 7.61 6.32

COOLING WATTS 890 890 1170 1170 1480 1480 1750 1750

EER 10 10 10 10 10 10 10 10

CFM HIGH SP 0.1” 424 424 482 482 532 532 565 565

CFM LOW SP 0.1” 370 370 421 421 475 475 525 525

CONDITIONED MAKE UP AIR (CFM)

55 55 55 55 55 55 55 55

HEATING BTUH 8400 8400 10900 10900 13400 13400 15500 15500

HEATING WATTS 820 820 1065 1065 1309 1309 1514 1514

COP 3 3 3 3 3 3 3 3

DEHUMIDIFIER 250W HEATER AMPS (OPT) 1.09 0.90 1.09 0.90 1.09 0.90 1.09 0.90

DEHUMIDIFIER 400W HEATER AMPS (OPT) 1.74 1.44 1.74 1.44 1.74 1.44 1.74 1.44

DEHUMIDIFIER AMPS 1.13 0.90 1.13 0.90 1.13 0.90 1.13 0.90

DEHUMIDIFIER WATTS 260 207 260 207 260 207 260 207

DEHUMIDIFIER LITERS/DAY* 7.90 7.90 7.90 7.90 7.90 7.90 7.90 7.90

DEHUMIDIFIER CFM 55 55 55 55 55 55 55 55

DEHUMIDIFIER CONTROL Automatic Automatic Automatic Automatic Automatic Automatic Automatic Automatic

Heating capacities specied in accordance with ANSI/AHRI standard 390 at conditions of 47 °F DB/43 °F WB outdoor and 70 °F DB/60 °F WB indoor. Wattage, Amperage, COP, EER listings include compressor,

evaporator motor and condenser fan motor. Cooling capacities specied in accordance with ANSI/AHRI standard 390 at conditions of 95 °F DB/75 °F WB outdoor and 80 °F DB/67 °F WB indoor.

*AHAM condition 60% RH, 80 °F DB

HEATING OPTIONS

Heating

Option

Voltage (1) Wattage B.T.U.s (2) Amps (3) MCA (4) MOP (Amps) Power Cord

B

208

230

277

2,050

2,500

2,500

7,000

8,535

8,535

10.46

11.47

9.63

13.1

14.3

12.0

15

15

15

6-15

6-15

7-20

C

208

230

277

2,950

3,600

3,600

10,070

12,290

12,290

14.78

16.25

13.60

18.5

20.3

17.0

20

20

20

6-20

6-20

7-20

E

208

230

277

4,100

5,000

5,000

14,000

17,070

17,070

20.31

22.34

18.65

25.4

27.9

23.3

30

30

30

6-30

6-30

7-30

(1) Voltage is 60Hz, Single Phase, Alternating Current and R.M.S. (2) Heating Capacity (B.T.U./Hr.) based on indoor

blower motor and heating elements. (3) Amp values are a combination of indoor blower motor and heating elements.

ELECTRICAL

EZVR

LINE VOLTAGE 208/230 208/230 208/230 277 277

MAXIMUM AMPERAGE 12 16 24 16 24

WALL SOCKET CONFIGURATION

RECEPTACLE NUMBER NEMA 6-15R NEMA 6-20R NEMA 6-30R NEMA 7-20R NEMA 7-30R

ELECTRICAL HEAT OPTIONS 2.5 2.5 - 3.6 4.2 - 5.0 2.5 - 4.2 2.5 - 4.2

Dehumidifier

Capabilities

Outdoor

% RH

Outdoor

Temp (F)

H2O Removal

(L/Day)

60

80

7.9

60

90

7.8

62

84

9.6

70

81

11.18

85

90

14.4

82

82

17.02

Manufacturer of Quality Air Conditioning and Heating Products • www.islandaire.com • sales@islandaire.com • (800)-886-2759

12

Product Information

e Dr. VTAC system is an add on system to our standard VTAC unit to provide conditioned make up air into

a space through the VTAC unit by providing up to 75 CFM of outdoor air 24/7 by forced fan and cycling dehu-

midier compressor based on outdoor relative humidity levels.

Dr. VTAC was created to solve issues with dehumidication in rooms and to introduce fresh air due to de-

ciencies of oxygen levels. Dr. VTAC is not only a VTAC, it is also a Conditioned Make Up Air unit. New

ASHRAE studies show that many illnesses in hotel rooms can be attributed to an oxygen-decient atmosphere.

Dr. VTAC solves this issue by introducing conditioned make up air that satises both humidity level introduc-

tion and supplied oxygen.

Dr. VTAC is a two-stage system. e primary unit is responsible for control of Sensible Heat that is introduced

into the room via make up air temperature and thermal load of the occupants. e secondary unit is primar-

ily a dehumidication unit that provides up to 75 CFM of outside fresh air into the room. e correction of

the Sensible Temperature comes from the main VTAC system, which provides additional dehumidication

with temperature correction. Overall unit eciency, as compared with standard VTAC’s, is approximately 3%

improvement. e compressor/dehumidication process is controlled by a humidistat (factory set at 50% RH)

that monitors the outdoor relative humidity level and is adjustable by a qualied service person. Below 50%

RH, compressor operation and dehumidication is stopped. However, fan operation continues to provide up

to 75 CFM of outdoor air into the room.

e dehumidication system has a temperature switch that monitors both the refrigeration and the outdoor air

temperatures. If the outdoor air falls below 38 °F, the compressor is disabled with fan operation continuing to

provide outdoor air into the space. All dehumidier controls and safeties are automatically reset. An optional

air tempering heater is available for the fresh air system for applications where operation in cold winter cli-

mates is required. Condensate from the dehumidier drains into the VTAC drain pan, where it is slung onto

the condenser coil for re-evaporation outside when the A/C runs. Excess condensate is drained into the wall

case which can then either drain to the outside through the louver OR be piped to a eld-supplied drainage

system.

ADVANTAGES OF THE DR. VTAC SYSTEM:

1. Lower installation/renovation costs than typical DOAS*

2. Decrease inconvenience to customer due to construction/installation of a DOAS* system

3. Precise humidity control in a room as compared to a simple VTAC vent or power vent system

4. Allows fresh make up air to travel entirely across sleeping and living areas of a room, exiting through a duct

or under the door.

*DOAS = Dedicated Outdoor Air System

Manufacturer of Quality Air Conditioning and Heating Products • www.islandaire.com • sales@islandaire.com • (800)-886-2759

13

Reversing Valve:

e reversing valve controls the direction of refrigerant

ow for both heating and cooling functions and remains

energized as long as the controls are in the heat posi-

tion. When the cooling controls are activated, the valve

automatically reverses to the cooling position.

NOTE: Be sure to connect reversing valve wiring to

the B (blue wire) connection of the thermostat for heat

pump applications.

Heat Pump Features

Heat pump models oer substantial savings over models

with conventional electric resistance heaters.

When the outdoor coil temperature is above 27 °F

(approximately 35 °F outdoor-air temperature), the heat

pump draws heat from outdoor air and uses it to heat

indoor air. Since the heat supplied to the room is the

result of reversing the refrigeration cycle, the heat pump

uses less power than a conventional heating system,

therefore reducing energy costs.

Outdoor ermostat:

During the heating cycle, the outdoor thermostat senses

outdoor coil temperature. If the outdoor coil tempera-

ture falls below 20 °F (approximately 35 °F outdoor-air

temperature), the unit automatically switches to a backup

electric heater. e compressor stops and a blower circu-

lates warm air produced by the heater.

e thermostat automatically switches the unit back to

heat pump operation when the outdoor coil tempera-

ture rises above 40 °F, which is enough to provide heat

to meet demand. e entire operation is completely

automatic.

Product Information (Cont.)

Manufacturer of Quality Air Conditioning and Heating Products • www.islandaire.com • sales@islandaire.com • (800)-886-2759

14

Dimensional Drawings

Units must be installed in accordance with all applicable codes. Ensure that there is adequate clearance for ser-

vicing and proper operation. A minimum clearance of 18 inches in front of the air return is required. Provide

additional space for the service technician to work on the unit. Ensure that drapes, beds, bedspreads, furniture,

etc., DO NOT block either the return or discharge air openings.

Your airow should be balanced based on many factors, such as available ESP, room CFM, and ductwork.

Consult an HVAC engineer for proper applications. Higher CFMs tend to increase sensible capacity, enhance

room circulation and increase duct noise, while lower CFMs tend to increase latent capacity and reduce noise.

Important Notes

‘A’ dimension determined by wall thickness and plenum size selected

‘B’ dimension minimum 4” for front installation,

‘B’ dimension minimum 5” for side installation (7” recommended)

‘C’ and ‘D’ dimensions minimum 3” for front installation

‘C’ and ‘D’ dimensions minimum 3” for side installation

‘E’ dimension minimum for 28” door - 33”

‘E’ dimension minimum for Islandaire Access Panel - 30”

Figure 1 Dimensional Drawings (Unit Top Down View)

2 1/4”

OUTDOOR GRILLE

PLENUM

1”

PLENUM

A

OUTDOOR WALL

23 1/8”

WIDE

VP/VR CHASSIS CASE

23 1/8”

DEEP

E

D

B

C

E

CLOSET WALL

Manufacturer of Quality Air Conditioning and Heating Products • www.islandaire.com • sales@islandaire.com • (800)-886-2759

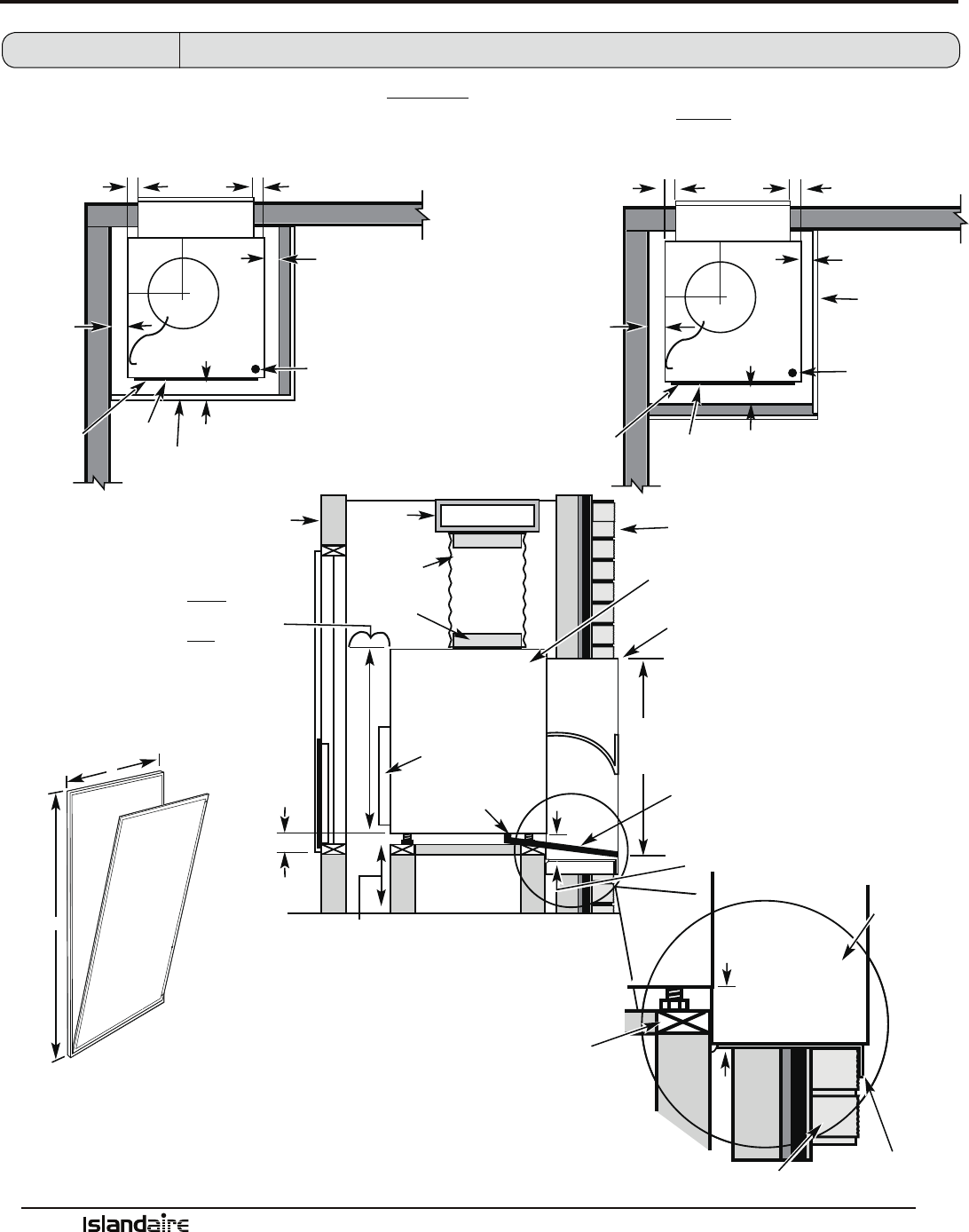

15

Dimensional Drawings (Cont.)

See page 16

REMOVE HEX

SCREW

REMOVE TOP AND

SIDE SCREWS,

ROTATE OUTWARDS

FULLY

REMOVE

SIDE

PANEL

SCREWS

PULL UNIT FORWARD SLIGHTLY,

THEN SLIDE OUT OF CASE

SIDE-MOUNTED CHASSIS REMOVAL:

Figure 1-A Dimensional Drawings (Unit and Platform)

23 1/8”

23 1/8”

31”

23 1/4” 23 1/4”

Manufacturer of Quality Air Conditioning and Heating Products • www.islandaire.com • sales@islandaire.com • (800)-886-2759

16

Dimensional Drawings (Cont.)

Side View

UNIT INSTALLED THROUGH FRONT OF

CASE (RECOMMENDED)

UNIT INSTALLED THROUGH

SIDE OF CASE

FILTER

BRACKET

FEMALE DRAIN

FITTING 3/4”

PLENUM CUTOUT

32-1/4”H x 20-1/8”W

INSIDE WALL

OUTSIDE WALL

RIGID

DUCTWORK

FLEXIBLE OR

RIGID DUCT

UNIT/CASE

WALL PLENUM - EXTEND

1/4” FOR CAULKING

EXTERIOR/OUTSIDE

EXTERNAL DRAIN LINE

BOTTOM OF CASE APPROX. 2”

ABOVE BOTTOM OF PLENUM

WALL PLENUM

BOTTOM OF CASE

APPROX. 2” ABOVE

BOTTOM OF PLENUM

PLATFORM

PLATFORM: 23-1/4” x 23-1/4”

SQUARE

MIN. LOAD CAPACITY: 230 LBS.

8” MIN. FOR

DRAIN ACCESS

• 4” MIN. FROM FRONT OF CASE - UNIT

INSTALLED THROUGH FRONT OF CASE

• 5” MIN. FROM FRONT OF CASE - UNIT

INSTALLED THROUGH SIDE OF CASE

• 3” MIN. FROM TWO SIDES OF CASE

OUTSIDE WALL

FIELD SUPPLIED

OUTER FLASHING

A

B

A: MINIMUM RECOMMENDED ACCESS DOOR WIDTH 30”

B: MINIMUM RECOMMENDED ACCESS DOOR HEIGHT 50”

Top View Top View

RTS CONNECTION

REMOVE FRONT

COVER TO GAIN

ACCESS

~2 1/4”

3” MIN.

4” MIN.

UNIT

FRONT

DOOR/ACCESS PANEL

~1”

3” MIN.

10-1/2”

10”

DUCT

11-3/4”

ELECTRICAL

CONNECTION

ARCHITECTURAL LOUVER

19-7/8”

AIR DISCHARGE

OUTLET

2-INCH (MIN.)

10-INCH (MAX.)

~2 1/4”

3” MIN.

3” MIN.

7” RECOMMENDED,

5” MIN.

UNIT

FRONT

DOOR/ACCESS

PANEL

~1”

11-3/4”

10”

DUCT

10-1/2”

ARCHITECTURAL LOUVER

ELECTRICAL

CONNECTION

19-7/8”

RTS CONNECTION

REMOVE FRONT COVER

TO GAIN ACCESS

Figure 1-C Dimensional Drawings (Chassis)

Manufacturer of Quality Air Conditioning and Heating Products • www.islandaire.com • sales@islandaire.com • (800)-886-2759

17

Installation Instructions - Wall Plenum

Wall Plenum

Since the VTAC unit itself does not install in the wall opening, the use of a wall plenum is necessary to contain

and separate the outdoor air paths to prevent the discharge air from being drawn back into the unit. e ple-

num must be able to hold water in the bottom without leaking into the wall cavity. e installation of ashing,

with a 45° drip-lip, is recommended below the plenum.

e plenum is not load bearing, so a proper header needs to be installed above the plenum just as over any

window opening in the wall. If the building construction is brick, concrete block, or other non self-supporting

material, a lintel must be installed over the plenum opening. e plenum is to be installed square and level

in the opening and secured to the wall construction with screws or nails in the sides located a minimum of 2”

from the bottom of the plenum. No nails or screws may be used in the bottom or top of the plenum to ensure

against water entering the wall cavity. e plenum must be caulked (on all four sides) along the outdoor wall

face and along the interior wall to prevent air inltration and water intrusion.

e wall opening location for the plenum must extend 1” below the top of the Installation Platform. Since the

platform must be a minimum of 8” o the oor, the cutout for the plenum must be a minimum of 7” plus the

thickness of the platform base, o the interior nished oor.

Islandaire oers ve plenums; the choice of the correct plenum is determined by the thickness of the building’s

exterior wall (see below). Each plenum is 19 7/8” wide by 32” high and requires a 20 1/8” wide by 32 1/4” high

cutout in the wall.

Prepare the closet ductwork for later connection to the case. Plenum duct should be insulated to prevent con-

densation and to reduce air noise.

PROPERLY LEVEL AND

SQUARE PLATFORM

ARCHITECTURAL LOUVER

EXTERIOR/OUTSIDE WALL

WALL PLENUM

CASE

Type 1: 6”D x 19 7/8”W x 32”H

Type 2: 8”D x 19 7/8”W x 32”H

Type 3: 10”D x 19 7/8”W x 32”H

Type 4: 12”D x 19 7/8”W x 32”H

Type 5: 15”D x 19 7/8”W x 32”H

Manufacturer of Quality Air Conditioning and Heating Products • www.islandaire.com • sales@islandaire.com • (800)-886-2759

18

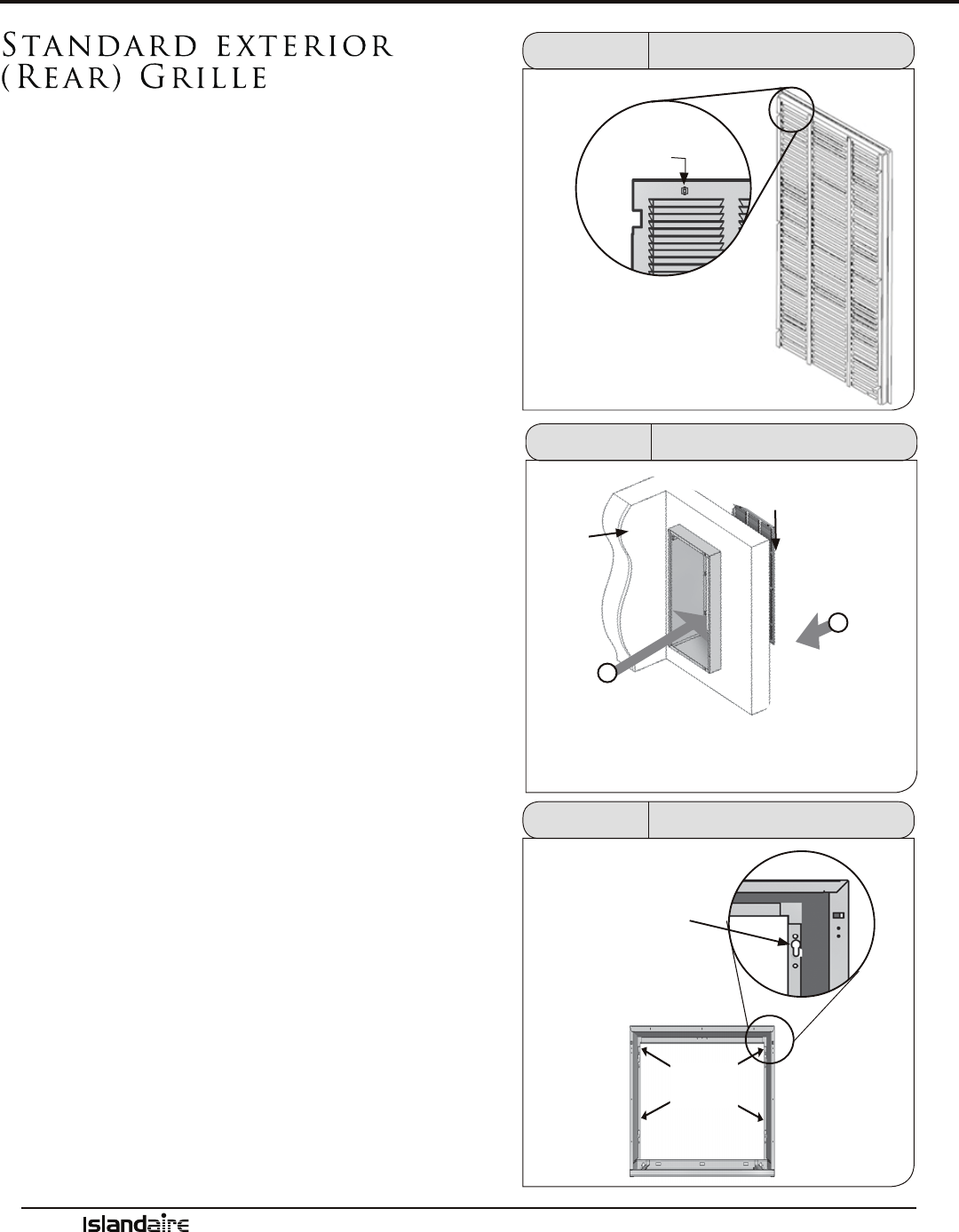

Installation Instructions - Exterior Grille

Standard exterior

(Rear) Grille

e standard exterior grille (louver) is mounted to the

exterior ange of the plenum and held in place with four

screws inserted from inside the enclosure closet. e

grille is designed specically for use with the VTAC unit

and the use of any other grille must be approved by Islan-

daire Air Conditioning Applications Engineering.

1. Prepare the grille for installation by installing the ve

plastic fasteners supplied through the holes in the

grille.

2. Guide the alignment pins, located on the lower right

and lower le hand corners of the grille into their

corresponding holes on the rear outside edge of the

plenum.

3. If installing the grille from inside the room, use a plas-

tic wire zip-tie or tie a short length of string or insu-

lated wire around several louvers as a holding device

in order to keep a rm grasp on the grille. Angle the

grille through the opening at the rear of the plenum,

then pull the grille back to the plenum and align the

screw heads to the hole. Be sure to keep a rm grip

on the grille to prevent it from dropping and/or caus-

ing possible injury and/or property damage.

4. Secure the grille to the plenum by installing screws

into the plastic fasteners. Be careful not to damage

fasteners by overtightening. Remove the holding

device (plastic wire zip-tie, etc.) when installation is

complete.

PLASTIC

FASTENER

Figure 2 Standard Grille Fastener

INSIDE

WALL

Figure 3 Standard Grille Installation

STANDARD

GRILLE

ANGLE THE GRILLE

THROUGH THE OPENING

AT BACK OF PLENUM

PULL FORWARD

TO INSERT SCREW

HEADS INTO

KEYHOLE SLOTS

HOLES

SECURE THE GRILLE TO THE

PLENUM BY TIGHTENING

SCREW HEADS IN HOLES.

DO NOT OVERTIGHTEN

Figure 4 Standard Grille Installation

Manufacturer of Quality Air Conditioning and Heating Products • www.islandaire.com • sales@islandaire.com • (800)-886-2759

19

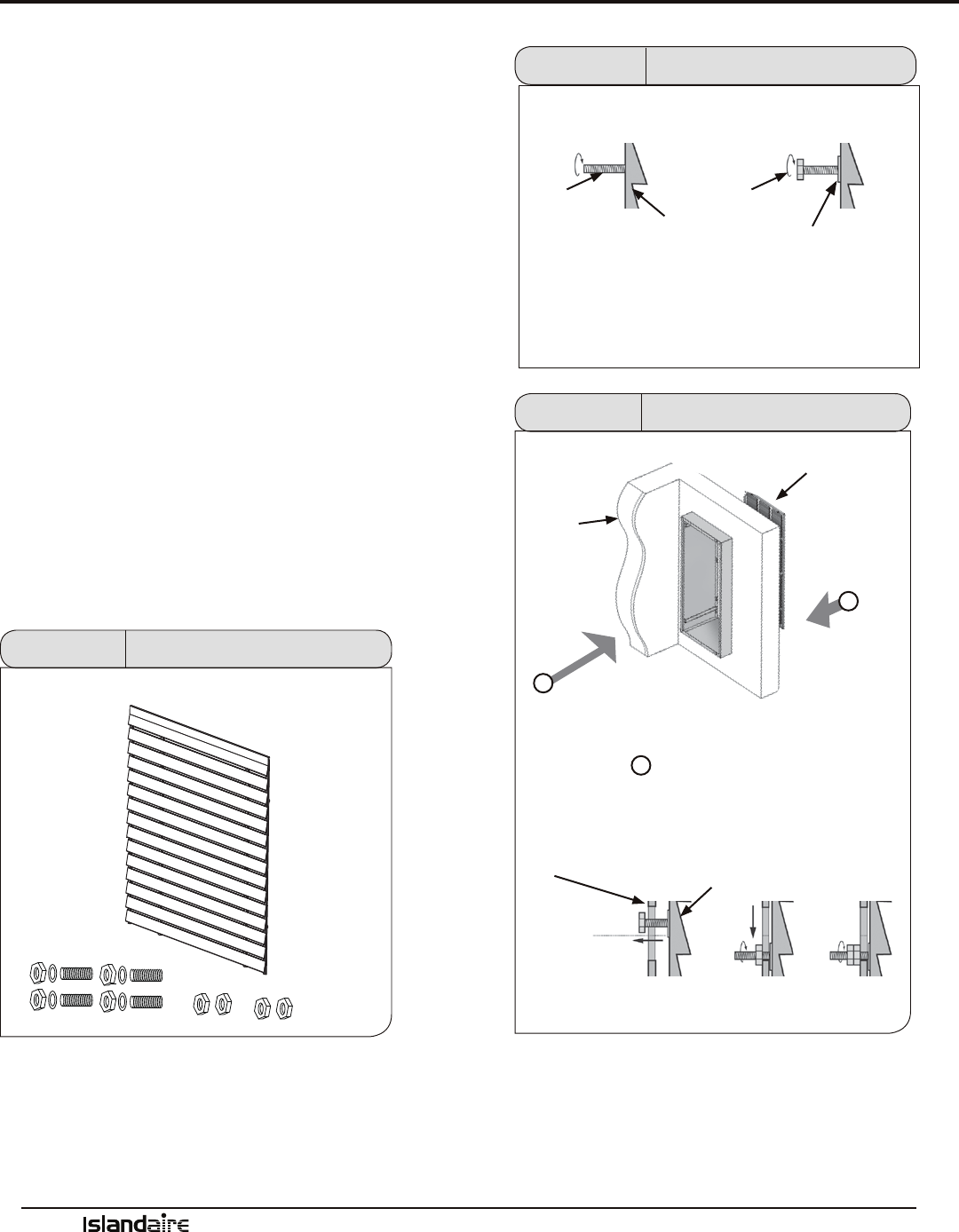

Installation Instructions - Exterior Grille

Architectural

Exterior (Rear) Grille

e architectural rear grille directs condenser airow

and provides a protective barrier for the outdoor coil.

Either the approved Standard or Architectural grille must

be installed before installing the chassis.

1. Install the four threaded studs into the threaded

openings on the inside face of the grille. Install a

washer and one hex nut to the end of each stud.

2. Manipulate the grille out through the rear ple-

num opening. Be sure to keep a rm grip on the

grille to prevent it from dropping and/or causing

possible injury or property damage.

3. Attach the grille to the plenum by aligning and

inserting the hex nut threaded onto the studs

through the holes in the plenum.

4. Secure the grille to the plenum by tightening the

hex nut and adding and tightening an additional

hex nut.

Architectural Rear Grille, 4 Studs, 4 Washers,

(8) Hex Nuts

Figure 5 Architectural Rear Grille Parts

STUD

HEX NUT

WASHER

INSTALL THE FOUR THREADED STUDS INTO THE THREADED

OPENINGS ON THE INSIDE FACE OF THE GRILLE. INSTALL

WASHERS AND HEX NUTS TO THE END OF EACH STUD.

Figure 6 Threaded Stud Installation

ARCHITECTURAL-

GRILLE

INSIDE

WALL

ANGLE THE GRILLE THROUGH

THE OPENING AT BACK OF

PLENUM

PLENUM

ARCHITECTURAL

GRILLE

PULL FORWARD TO GUIDE HEX NUTS

THROUGH HOLES IN PLENUM, THEN

TIGHTEN HEX NUTS. SECURE WITH AN

ADDITIONAL HEX NUT.

Figure 7 Arch. Rear Grille Installation

1

2

2

ARCHITECTURAL

GRILLE

Manufacturer of Quality Air Conditioning and Heating Products • www.islandaire.com • sales@islandaire.com • (800)-886-2759

20

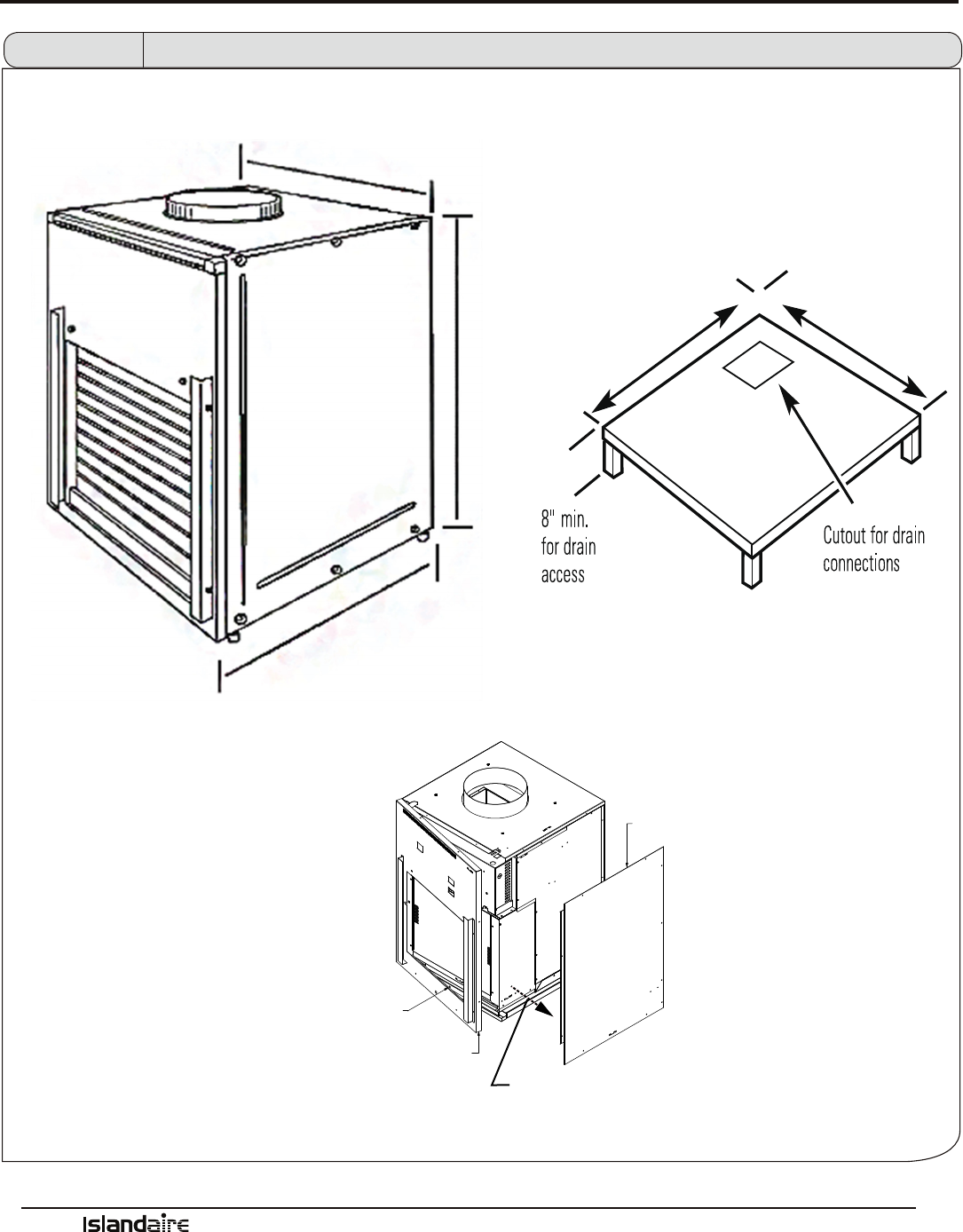

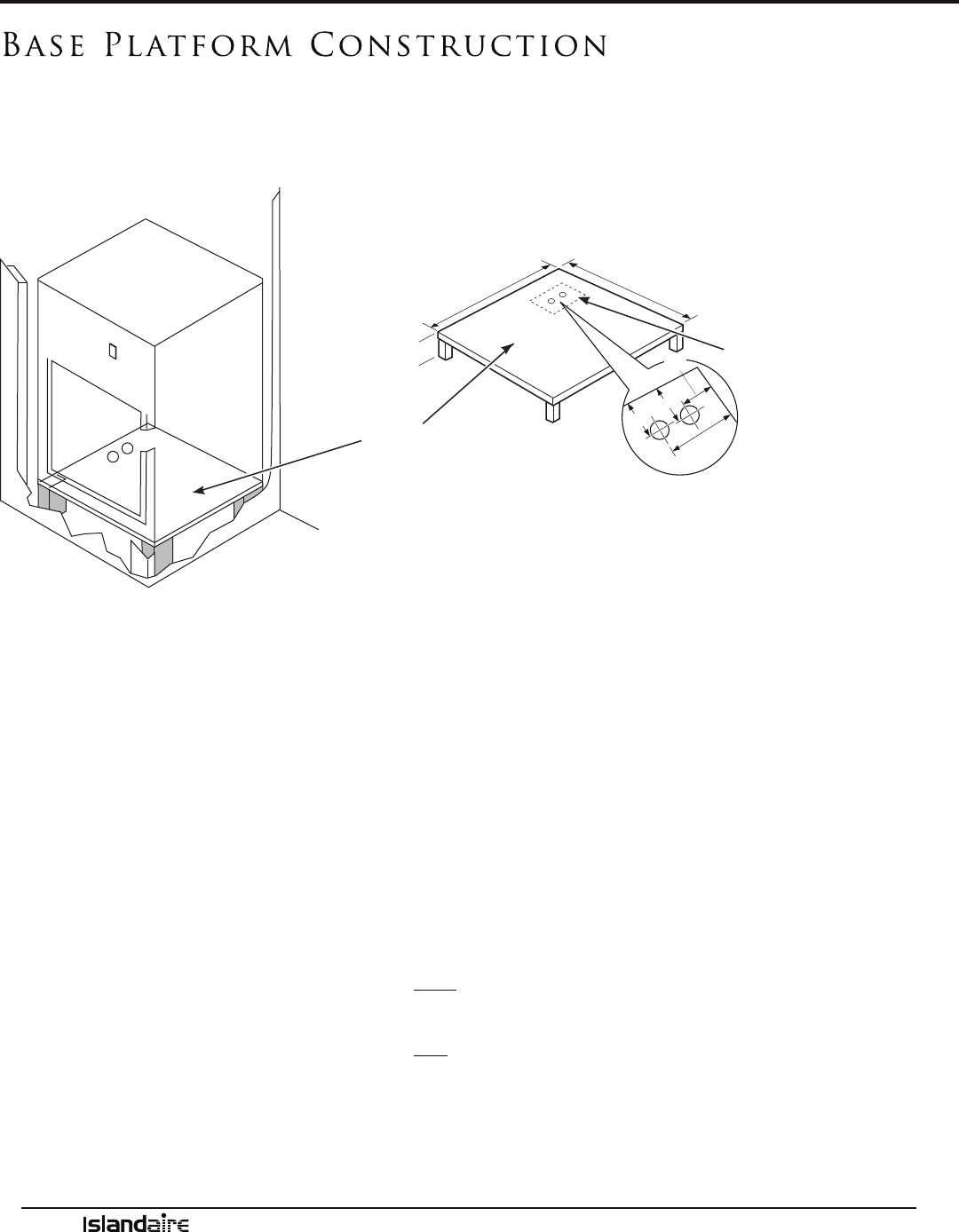

Installation Instructions - Base Platform

Base Platform Construction

e VTAC unit requires a eld-supplied base platform (having a load-bearing capacity of 230 lbs. mini-

mum). For warranty purposes, the base platform must be constructed to ensure the unit chassis can be

removed through the access panel. Proceed as follows:

1. Construct a 23 1/4” min. x 23 1/4” min. square platform with legs to raise platform a minimum of 8”

(12” recommended), see diagram above.

2. Make the drain hole cutout(s) as follows

• Primary Drain - Centerline of drain is approximately 4.695” from le platform edge and 8.875”

from back platform edge.

• Secondary Drain - Centerline of drain is approximately 6.625” from le platform edge and 5.625”

from back platform edge.

3. Place the platform in the utility closet large enough to provide the following clearances between it and

the interior surface of the walls/door/panel:

NOTE: When determining the closet depth, consideration must be given to the fact that the ple-

num will protrude into the closet because the plenum will be thicker than the exterior wall.

• If VTAC unit is to be installed through the front of case: 4” minimum clearance from the front of

the platform to inside of the closet door, 3” minimum clearance from each side of the case.

• If VTAC unit is to be installed through the side of case: 5” minimum clearance from the front of the

case, 5” minimum clearance from each side.

4. e platform legs must be positioned so access to the unit drain connections are not blocked. Align

the platform with the opening of the wall plenum and secure to the oor using appropriate brackets

and screws.

PLATFORM

6.0

6.2

4.62

8.7

LEFT SIDE OF PLATFORM

23.25” MIN

8” MIN FOR

DRAIN ACCESS

BACK SIDE OF PLATFORM

23.25” MIN

CUTOUT FOR DRAIN

CONNECTION(S) (SEE

NOTE BELOW)

NOTE: Specic cutout size and locations for drain con-

nections must be conrmed by the installer for the given

installation.

Manufacturer of Quality Air Conditioning and Heating Products • www.islandaire.com • sales@islandaire.com • (800)-886-2759

21

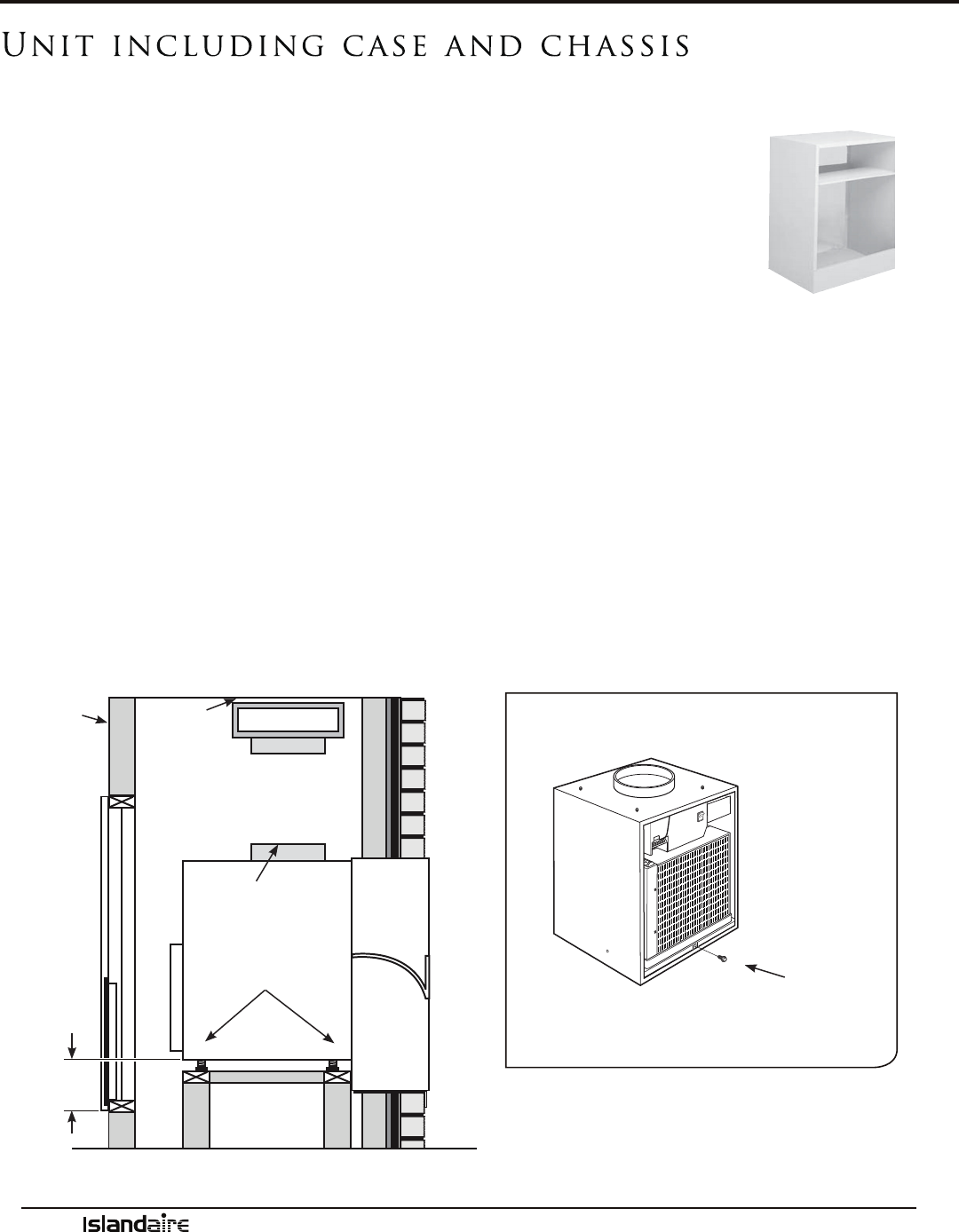

Unit including case and chassis

e VTAC unit is packaged with the case and the front panel in place (lter not included).

1. Remove the front case panel and pull the unit chassis out of the case. Remove

the side panel if a side installation is to be made.

2. Place the empty case onto the base platform in the closet with the outdoor side

facing the wall plenum and slide unit up to plenum.

3. Level the case side-to-side and front-to-back using the four leveling legs.

4. Using the holes in the bottom of the case as guides, drill holes in the mounting

platform. Use four eld-supplied bolts, washers and nuts to secure the case to the platform. Do not

tighten the bolts to the point of distorting the case. Failure to properly secure the case to the platform

may result in excessive unit vibration and increased noise level.

5. Align the case with the plenum opening and attach using six eld-supplied sheet metal screws (stain-

less screws recommended).

6. Slide the unit chassis into the case, either through the front or side panel opening. Push the unit all of

the way into the case until it stops.

NOTE: Either of the case sides may be removed to enable the unit to be slid into the case.

7. With the chassis in position in the case, replace the side panel (if removed).

8. Ground the unit to the case by installing the front case-to-unit hex bolt.

CASE

INSIDE WALL

RIGID

DUCTWORK

AIR DISCHARGE

OUTLET

LEVELING LEGS

2-INCH (MIN.)

10-INCH (MAX.)

HEX BOLT

Installation Instructions - Case & Chassis

Manufacturer of Quality Air Conditioning and Heating Products • www.islandaire.com • sales@islandaire.com • (800)-886-2759

22

Installation Instructions - Drains

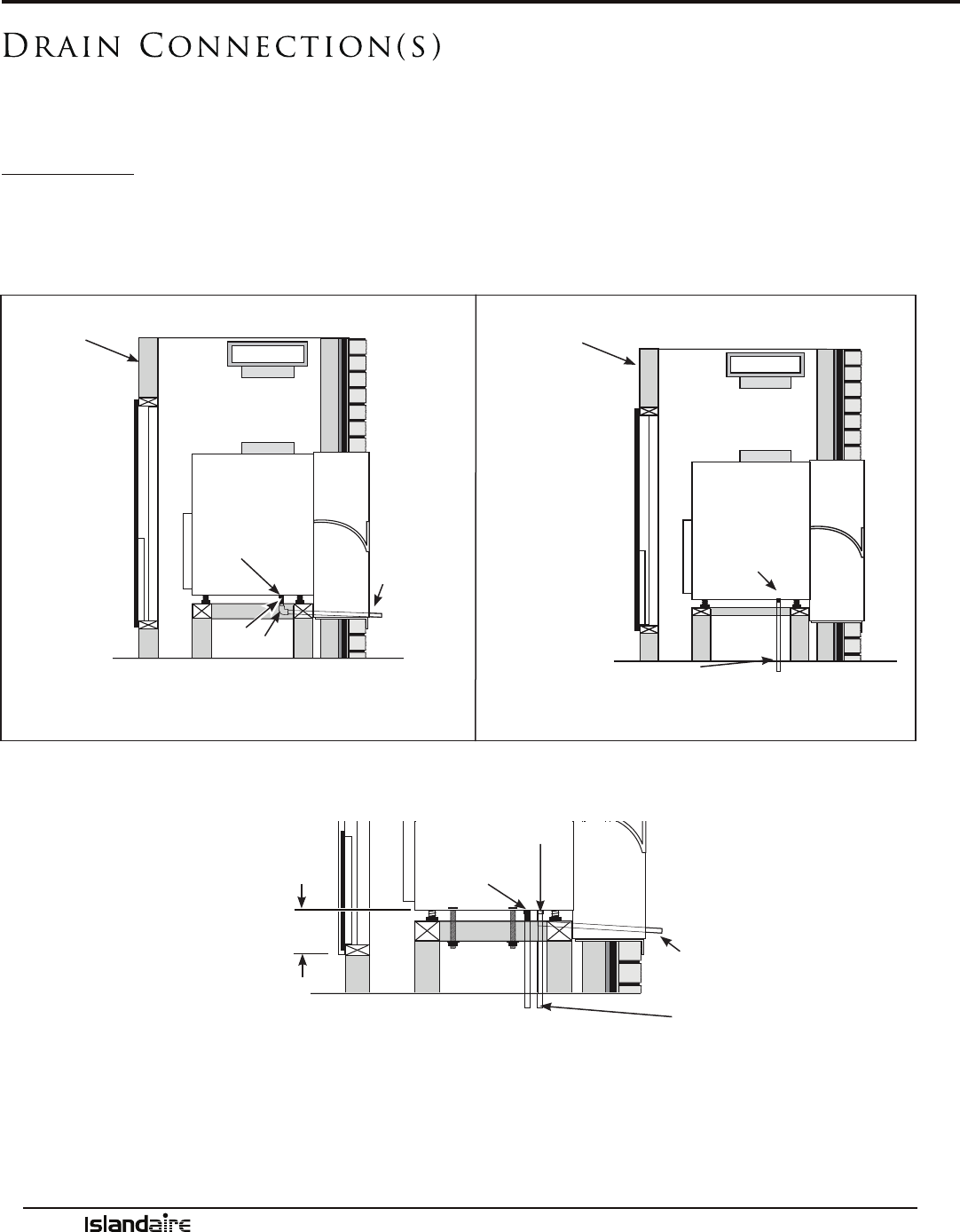

Drain Connection(s)

e VTAC unit is equipped with two drain ttings (primary and secondary drains). An external or an

internal drain must be attached to the primary drain connector. e secondary drain is provided for con-

nection when required by state and local codes. Refer to local codes for proper installation of the drains.

External Drain:

Attach a 90° PVC elbow to the unit’s female 3/4” NPT drain connector. Use the other end of the elbow to

run a 3/4” schedule 40 PVC pipe through the knockout hole of the wall plenum to the outside. A notch

must be cut in the rear grille (louver blade) to allow tube to pass through. Seal the gap between the wall

plenum hole and PVC tube.

* Ensure drain lines going out the plenum are sloped downward to allow water to drain out.

e secondary drain hole is shipped open (unplugged) and must either be plugged if not used or con-

nected to an independent drain system. If a secondary drain system is used, attach a 90° schedule 40

PVC elbow to the secondary drain hole directed toward the secondary drain system. If a secondary drain

system is NOT used, install a 3/4” schedule 40 PVC plug to cap the hole. If the secondary drain is not

used, seal its drain port with a 3/4” MNPT plug.

PVC

90° ELBOW

PVC

(EXTERNAL

DRAIN)*

INSIDE WALL

FEMALE DRAIN

FITTING 3/4”

Side View

Primary Drain (External)

Side View

INSIDE WALL

PVC

(INTERNAL DRAIN)

FEMALE DRAIN

FITTING 3/4”

Primary Drain (Internal)

SECONDARY 3/4” DRAIN

OPTION. IF NOT USED,

SEAL WITH A MNPT PLUG.

PRIMARY FEMALE

DRAIN FITTING

3/4”

NOTE: PIPING IS NOT

SUPPLIED WITH THE UNIT.

OBTAIN LOCALLY.

EXTERNAL

DRAIN OR

INTERNAL

DRAIN(S)

2-INCH (MIN.)

10-INCH (MAX.)

Manufacturer of Quality Air Conditioning and Heating Products • www.islandaire.com • sales@islandaire.com • (800)-886-2759

23

Installation Instructions (Power Cord, Duct)

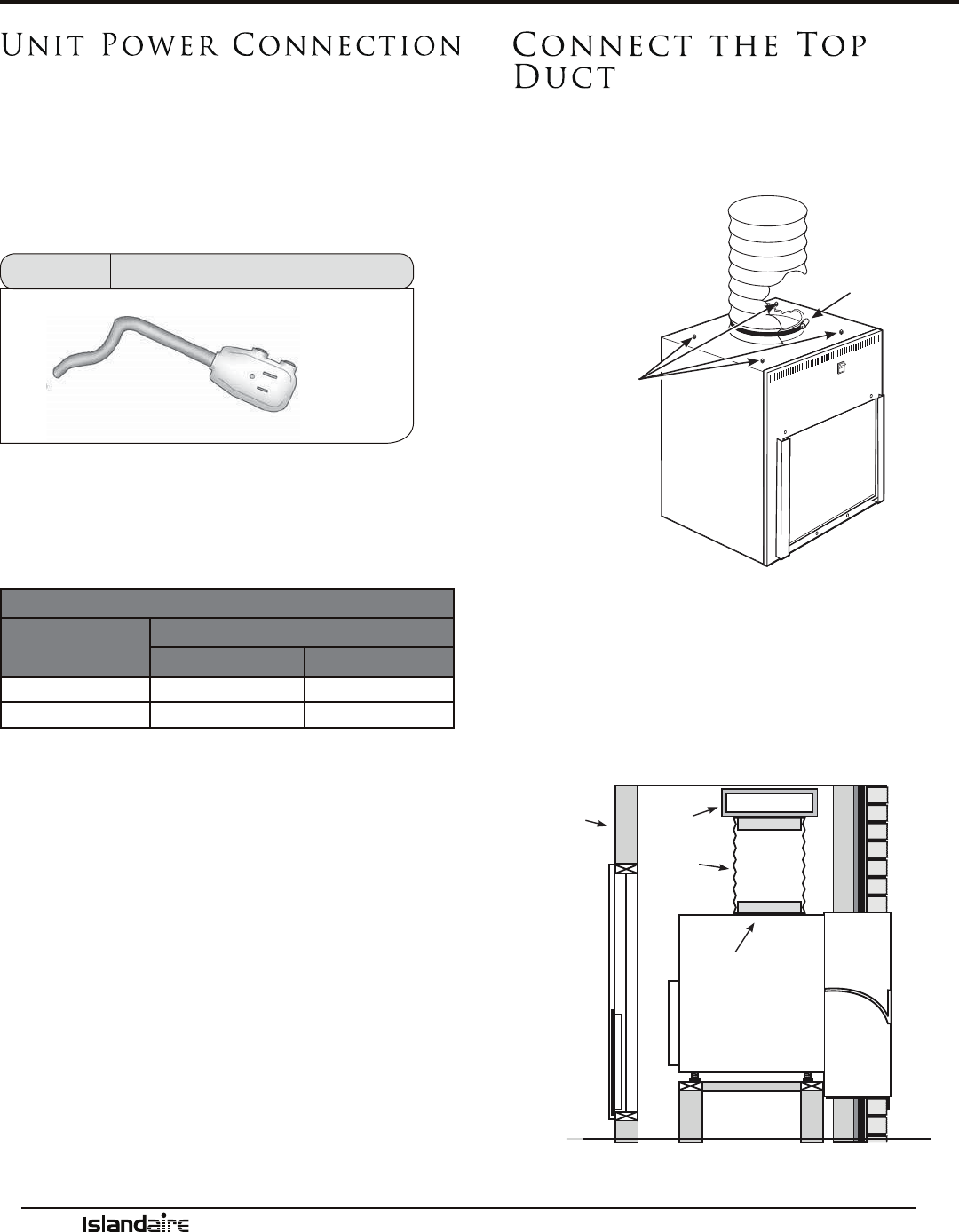

Unit Power Connection

1. 230/208V units are equipped with LCDI or AFCI

power cords and can open the electrical circuit to

the unit. In the event the unit does not operate,

check the reset button located on or near the head

of the power cord as part of the normal trouble-

shooting procedure. Make power connections to

the unit (refer to WIRING DIAGRAMS section).

2. Once the unit is properly wired, measure the unit

supply voltage. Voltage must fall within the voltage

utilization range as shown in the table below.

VOLTAGE MEASUREMENTS

OPERATING VOLTAGE

UNIT VOLTAGE RATING

VOLTAGE UTILIZATION RANGE

MINIMUM MAXIMUM

230/208 197 253

265 238 292

Figure 8 LCDI Cord

Connect the Top

Duct

1. Seal the case top duct to the VTAC unit chassis

by turning the four case top duct adjusting screws

until they are tight.

2. A 10” diameter ange on the air discharge outlet

is used to connect to eld supplied, insulated,

exible or rigid transition duct with an adjustable

ring clamp. Flexible duct may be used for transi-

tions only, rigid duct must be used for 90° bends

and tees. Do not use exible duct for unsup-

ported runs of ve feet or more. Extra exible

duct slack can greatly increase static pressure.

FLEXIBLE

OR RIGID

DUCTWORK

CLAMP

CASE TOP

DUCT ADJUST-

ING SCREWS

AIR DISCHARGE

OUTLET

INSIDE

WALL

RIGID DUCT-

WORK

FLEXIBLE

OR RIGID

DUCTWORK

Manufacturer of Quality Air Conditioning and Heating Products • www.islandaire.com • sales@islandaire.com • (800)-886-2759

24

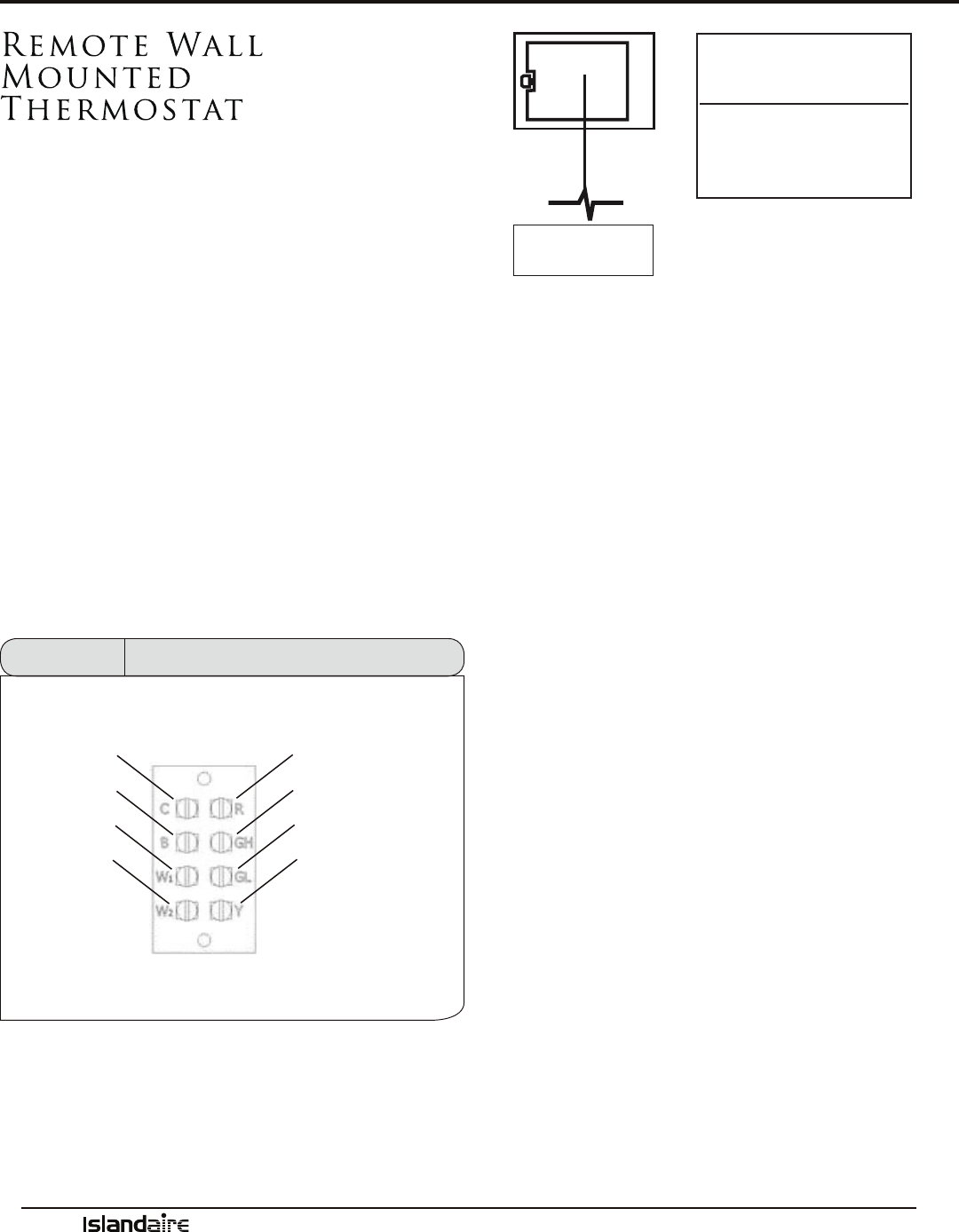

THERMOSTAT

MAXIMUM WIRING

LENGTH FOR THERMOSTAT

CONNECTION TO UNIT:

66 FT. FOR 18 AWG

60 FT. FOR 20 AWG

(AWG - AMERICAN WIRE GAUGE)

UNIT CONNECTIONS

Wireless Wall

Mounted Thermostat

Wireless wall thermostats are designed to provide

precise thermostat control without the installation

labor and expense of wiring.

• Powered by AA batteries

• Mounts in any suitable location that will pro-

vide an accurate room temperature reading.

• Large LCD display provides the user with

current room temperature, set point tempera-

ture, time, program interval, and other system

status information.

Remote Control Node

Used with a wireless wall thermostat, the RCN com-

municates with the thermostat using unlicensed 900

MHz, radio frequency range.

Remote Wall

Mounted

Thermostat

e VTAC unit can be controlled by any remote

electronic thermostat that can interface with RCB-

WYG terminals. In terms of outputs, there are two

types of thermostats: mechanical and solid-state.

Refer to the manual provided with the thermostat

for proper connections and settings.

A Remote ermostat Terminal Block is available,

and is located on top of the control box, behind the

front panel of the case. It provides a connection

for a remote thermostat and energy management

inputs.

NOTE: Ensure power to the unit is shut o prior to

making any electrical connections.

1. Connect the thermostat wires to the unit. You

can wire any type of 24 VAC thermostat straight

into the Remote ermostat Terminal Block.

Figure 9

Thermostat Terminal Block

R

GH

Y

GL

C

B

W2

W1

Installation Instructions - Thermostat

Manufacturer of Quality Air Conditioning and Heating Products • www.islandaire.com • sales@islandaire.com • (800)-886-2759

25

Terminal W1 (White)

When this low voltage terminal is connected to

the R terminal, and the unit is in the remote mode,

rst hydronic heat is attempted, and electric heat

is switched on as backup (the GL and GH terminal

must also be connected to the R terminal). is is

subject to the congured heat modes available.

Terminal GL (Orange)

When this low voltage terminal is connected to

the R terminal, and the unit is in remote mode, the

blower/fan will be requested for operation on low

speed.

Terminal C(Black)

Low voltage terminal, 24 VAC common, to provide

opposite polarity voltage to wall thermostat.

Terminal R (Red)

Low voltage terminal to supply voltage to an exter-

nal wall-mounted thermostat. is terminal is

capable of supplying 100 mA at 18-30 VAC RMS

over the entire input voltage range specied.

Terminal GH (Green)

When this low voltage terminal is connected to

the R terminal and the unit is in remote mode, the

blower/fan will be requested for operation on high

speed.

Terminal B (Blue)

When this low voltage terminal is connected to the

R terminal and the unit is in the remote mode, the

reversing valve is energized. Hydronic and electric

heat shall be attempted as backups if the B terminal

is asserted and the compressor is locked out or dis-

abled. is is subject to the congured heat modes

available.

Terminal Y (Yellow)

When this low voltage terminal is connected to

the R terminal, and the unit is in remote mode, the

compressor will be switched on (the GL or GH ter-

minal must also be connected to the R terminal).

Remote Thermostat Interface

During a call, the remote thermostat will pass R back to the controller on a respective terminal. See

below for descriptions of each terminal.

Installation Instructions - Thermostat

(Cont.)

Manufacturer of Quality Air Conditioning and Heating Products • www.islandaire.com • sales@islandaire.com • (800)-886-2759

26

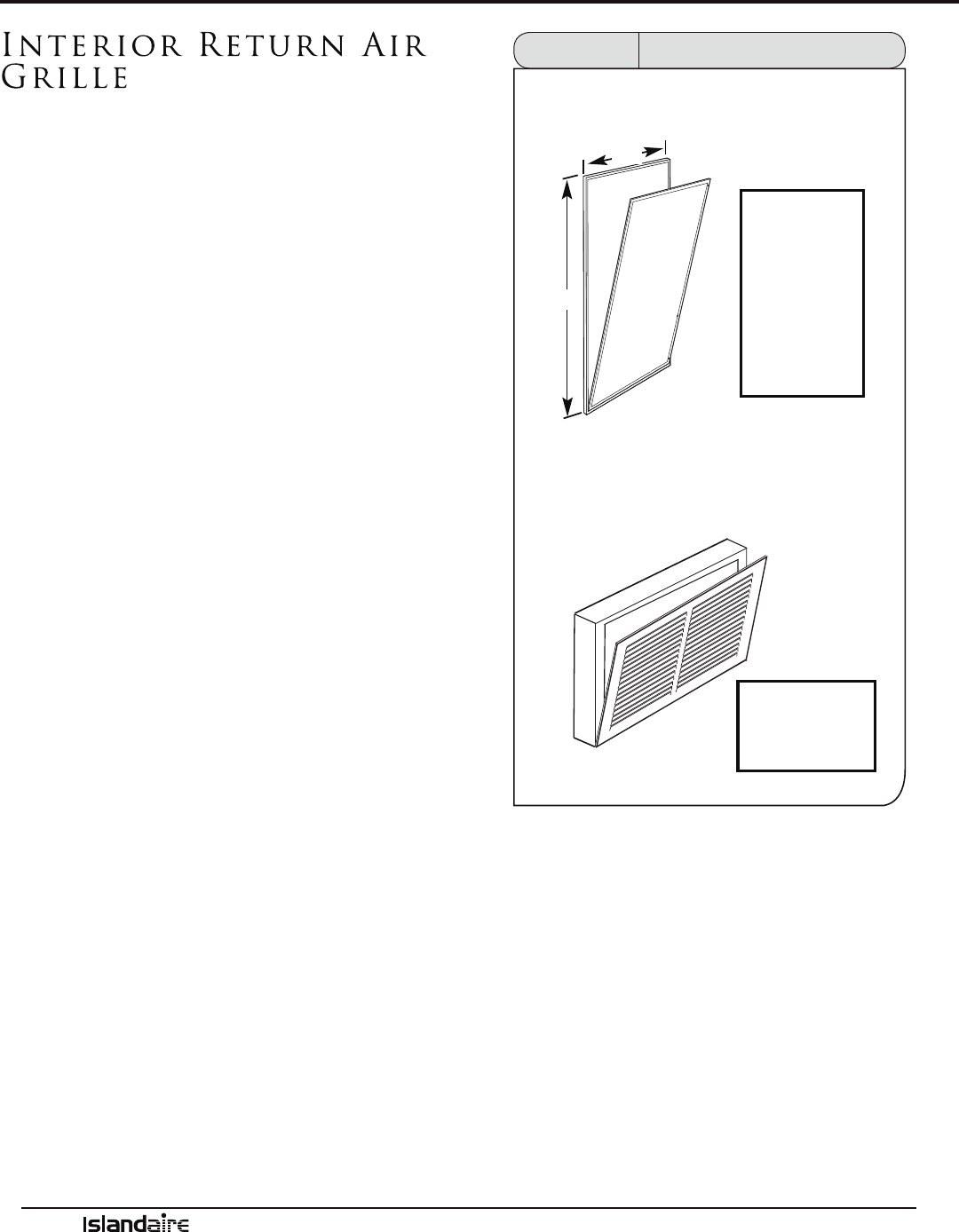

Installation Instructions - Interior Grille

Interior Return Air

Grille

e return air from the room to the VTAC unit

enters the enclosure closet using a return air grille

(see gure 10). A wall-mounted, front access panel

(item 1) in combination with a wall-mounted,

return air grille (item 2) is required.

1. e front access panel requires a 28” wide by 48”

high cutout in the door.

2. e return air grille (item 2) is designed to be

installed in a 20” wide by 20” high cutout in

the wall. An air lter can t into the bracket in

the rear of the return air grille or in the bracket

located on the front panel of the VTAC unit.

3. A sound-reduction louvered panel that mounts in

the door is also available. e sound-reduction

panel requires a 28” wide by 48” high cutout in

the door. e air lter would be installed in the

lter bracket located on the front panel of the

VTAC unit.

Figure 10 Interior Grille Installation

50”

ITEM 1: The front access panel - must be lined up with

the cutout on the VTAC unit case

ITEM 2: Return Air Grille

CUTOUT

DIMENSIONS

28”W x 48”H

30”

CUTOUT

DIMENSIONS

20”W x 20”H (min.)

Manufacturer of Quality Air Conditioning and Heating Products • www.islandaire.com • sales@islandaire.com • (800)-886-2759

27

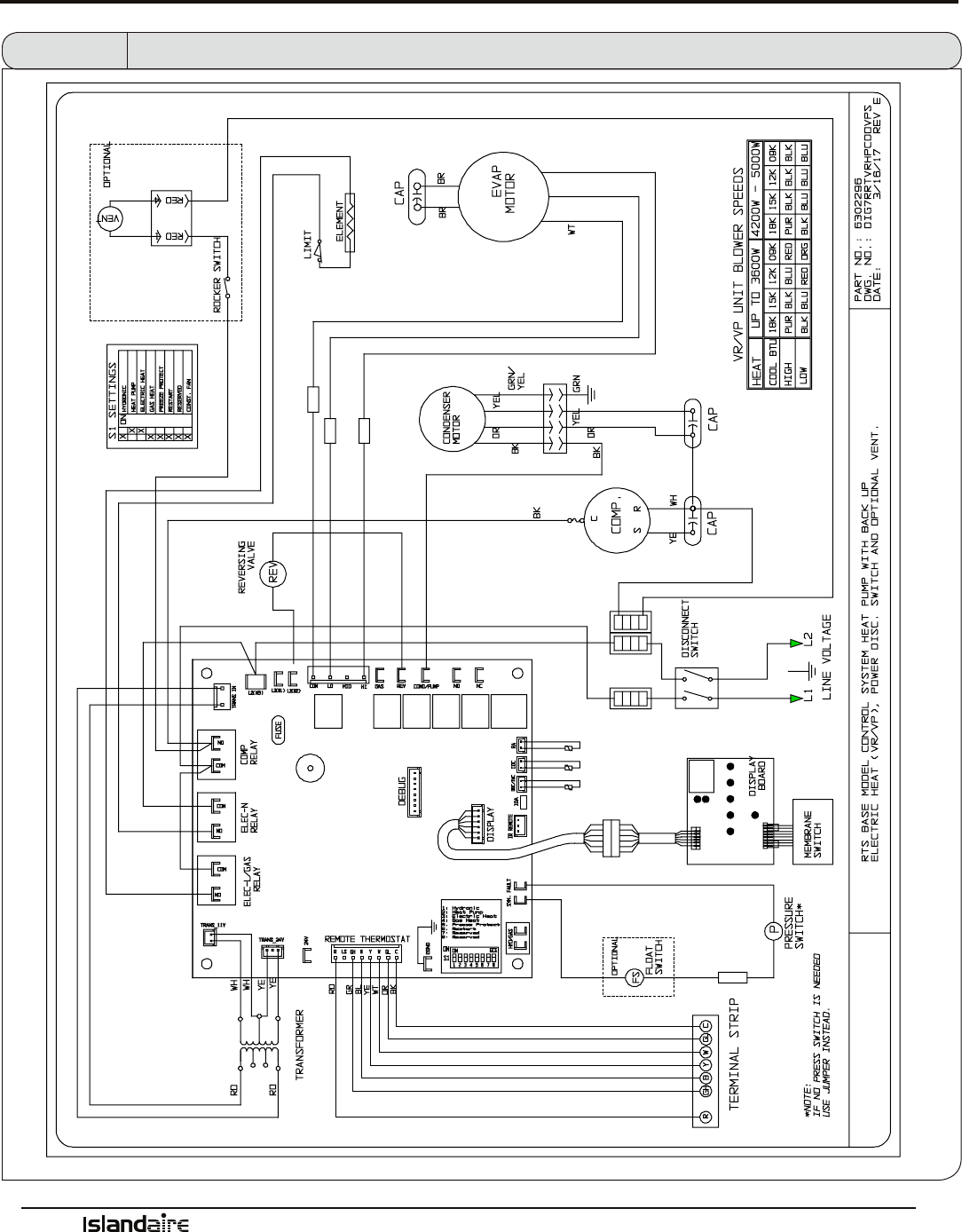

Wiring Diagrams

Figure 11 Wiring Diagram - EZ VP Series VTAC Unit

*NOTE: ABOVE DIAGRAM IS TYPICAL. FOR UNIT SPECIFIC WIRING, REFER TO DIAGRAM PROVIDED WITH UNIT (ENCLOSED IN VINYL POUCH)

Manufacturer of Quality Air Conditioning and Heating Products • www.islandaire.com • sales@islandaire.com • (800)-886-2759

28

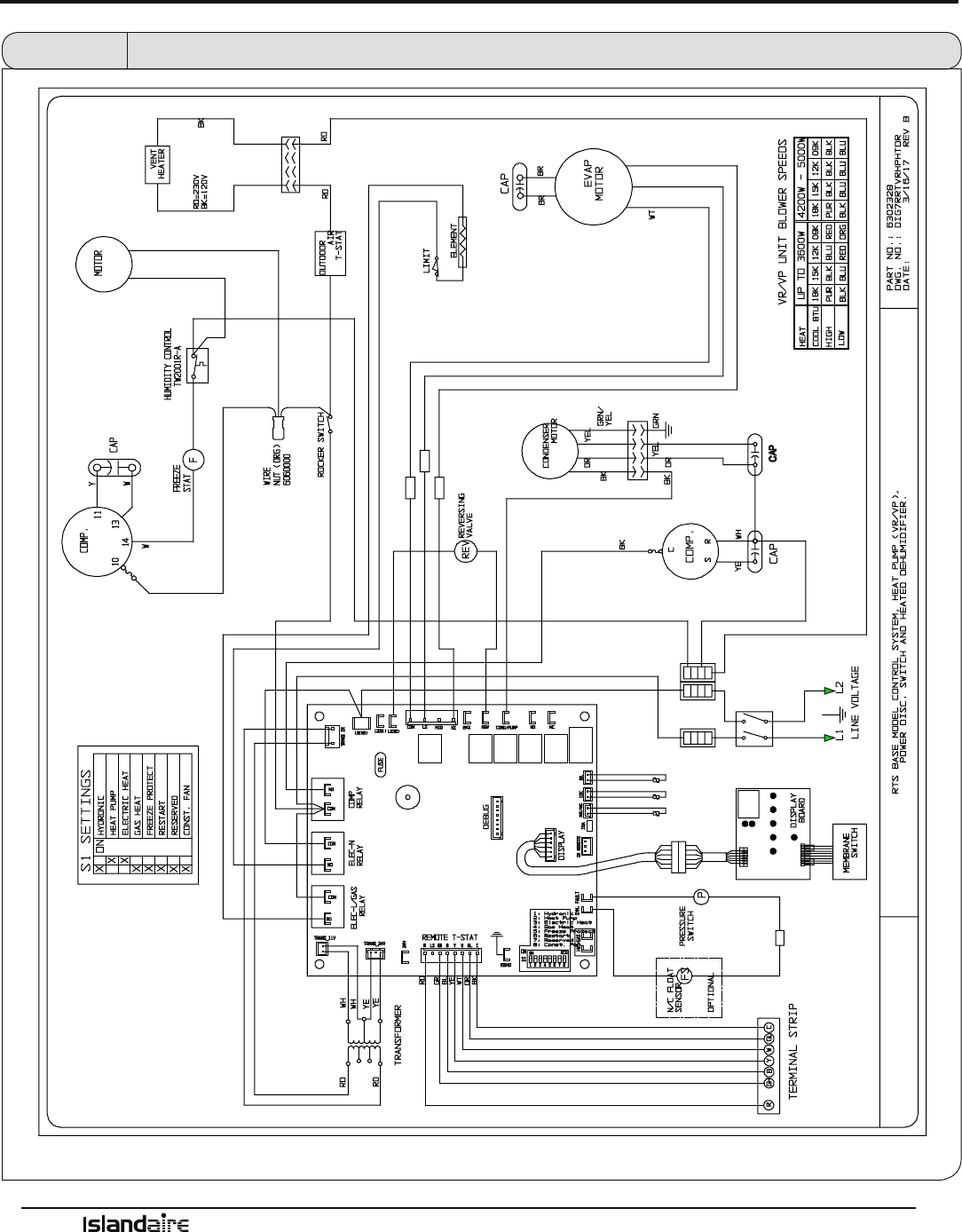

Wiring Diagrams (Cont.)

Figure 12 Wiring Diagram - EZ VR Series VTAC Unit

*NOTE: ABOVE DIAGRAM IS TYPICAL. FOR UNIT SPECIFIC WIRING, REFER TO DIAGRAM PROVIDED WITH UNIT (ENCLOSED IN VINYL POUCH)

Manufacturer of Quality Air Conditioning and Heating Products • www.islandaire.com • sales@islandaire.com • (800)-886-2759

29

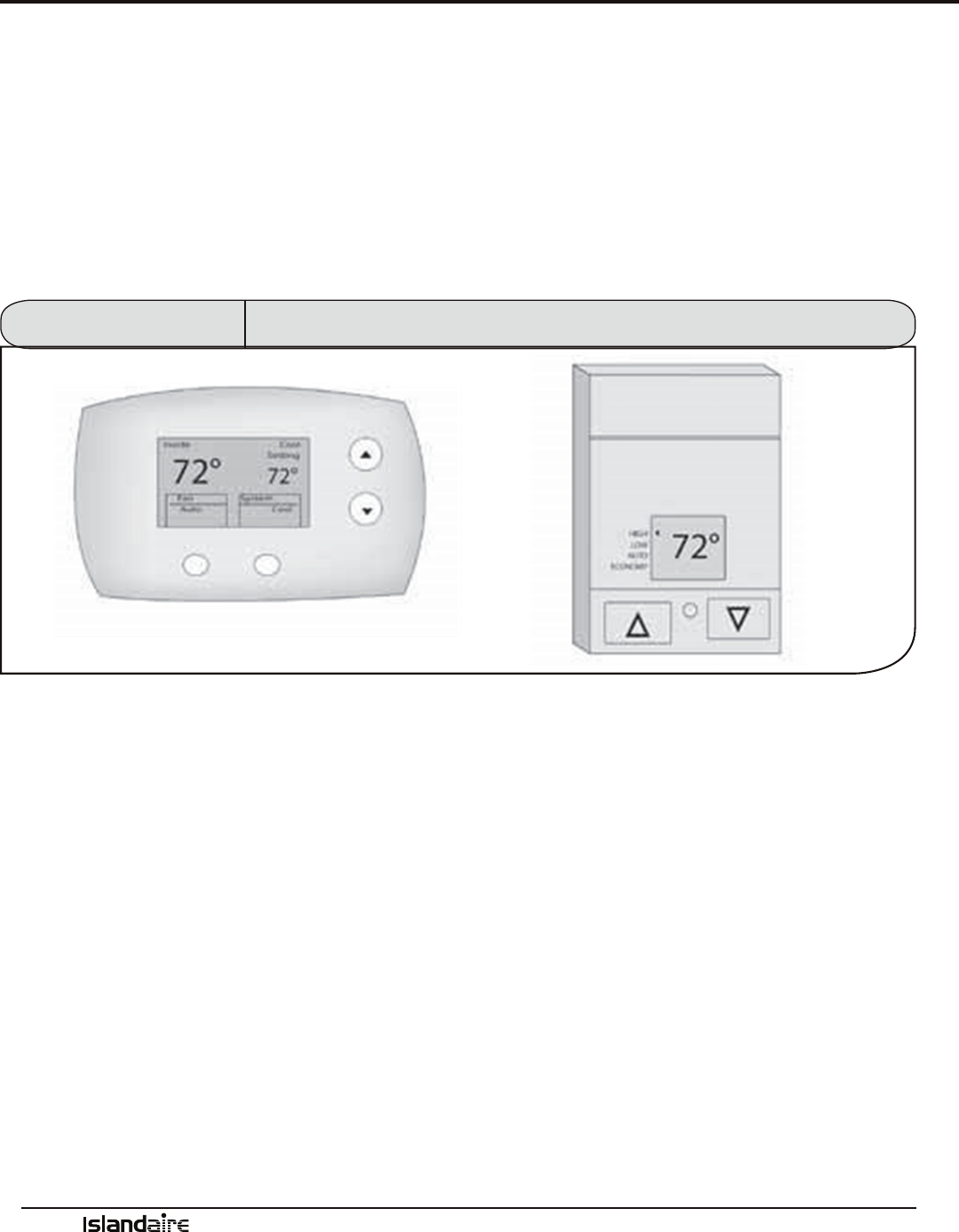

System Controls and Management

USER INTERFACES

e Islandaire EZVP VTAC can be operated using several dierent control systems. Described below are some of

the important control features and a brief description of their functions.

Wall Thermostats

Terminal connections on the main control board allow easy conversion from an on-board control panel to a wall-

mounted thermostat control (wired or wireless).

See page 24 & 25 for full details

Front Desk Control

Low voltage terminals on the main control board allow easy connection to a front desk energy management

system. Front desk controls allow the unit to be operated from a remote location. Front desk controls can reduce

energy consumption by allowing front desk personnel to turn the unit o when a room is vacant.

Figure 13

Wall Thermostats

Manufacturer of Quality Air Conditioning and Heating Products • www.islandaire.com • sales@islandaire.com • (800)-886-2759

30

System Controls and Management (Cont.)

Diagnostic Software

e smart logic control performs self-diagnostic tests

that inform service personnel about possible problems.

Error codes are continuously displayed during trouble-

shooting and maintenance until the problem has been

resolved.

Custom Operation

and Continual

Room Temperature

Monitoring

e smart logic control utilizes a built-in sensor for mea-

suring room temperature. When a

pre-determined (user-dened) set point is reached, smart

logic controls automatically adjusts the unit operation to

maintain the room temperature.

Controls Logic

e Islandaire VTAC unit is equipped with an electronic system that runs smart control logic with associated sen-

sors. Built-in safety features protect the unit from the damaging eects of freezing temperatures and power inter-

ruptions. Energy management functionality allows the unit performance to be customized to control its power

consumption. Displaying fault codes help personnel quickly correct any problems if they occur.

Listed below are the built-in automatic features and a brief description of their functions. See Performance Speci-

cations section starting on page 33 for full details of all functions.

Room Freeze

Prevention

e indoor freeze protection monitoring system prevents

unoccupied rooms from reaching freezing levels that can

damage plumbing and xtures. is feature is automatic

regardless of mode and does not require any additional

settings. is feature can be turned on or o by adjusting

DIP switch settings on the main control board.

High Temperature

Compressor

Protection

e life of the compressor is extended through built-in

temperature protection. e system will initiate a com-

pressor lockout if the compressor temperature exceeds

154 °F or if the outdoor air temperature falls below 35 °F.

Low Temperature

Compressor

Protection

An indoor frost sensor will disable the operation of the

compressor if freezing conditions exist. is protects

the compressor from damage due to airow reduction

or low outdoor air temperature. When the coil tempera-

ture rises to a safe temperature the compressor resumes

normal operation.

Manufacturer of Quality Air Conditioning and Heating Products • www.islandaire.com • sales@islandaire.com • (800)-886-2759

31

OPERATING GUIDELINES

• Do not block airow. Ecient operation of the

unit depends on free circulation of air. Paper,

leaves, and other debris can reduce eciency and

cause serious damage to the compressor.

• Ensure that objects such as drapes, furniture, or

plants are not blocking the supply and return

airow.

• Do NOT operate unit with front panel removed or

without lter, as this will void any warranties.

• Keep doors and windows closed. Leaving them

open will increase the workload on the unit and

will result in higher operating cost and excessive

condensate.

Do NOT operate the unit while the building is still

under construction or restoration. Construction dust

can clog the lter and cause permanent damage to other

components.

Freeze Protection Feature

If the temperature in a vacant room falls

below 50°F the freeze prevention thermo-

stat automatically starts the heating cycle to

prevent freezing conditions. All other opera-

tions will be disabled until the temperature

rises above 58°F. When the temperature of the

freeze prevention thermostat rises above 58°F,

the system will resume normal operation.

Heater Safety Feature

When the heater is powered o, fan will

automatically stay on and run for 60 seconds

to ensure the removal of residual heat.

System Controls and Management (Cont.)

Auto Restart Feature

To prevent multiple units from powering up

simultaneously after a power outage, there will

be a random 5 to 15 second delay before the

unit turns on after power has been restored.

Memory Recall Feature

e smart logic control utilizes “non-volatile”

memory; computer memory that can retain

stored information when not powered. is

allows all control settings to be saved and

recalled after a power failure or if power is

disconnected while servicing the unit.

Compressor Short Cycle Protection

Built-in 3 minute timing delay: If cycle is

interrupted, the compressor will not restart for

3 minutes. On all initial power ups there is a

one-time, 3-minute time delay before the unit

will function.

Manufacturer of Quality Air Conditioning and Heating Products • www.islandaire.com • sales@islandaire.com • (800)-886-2759

32

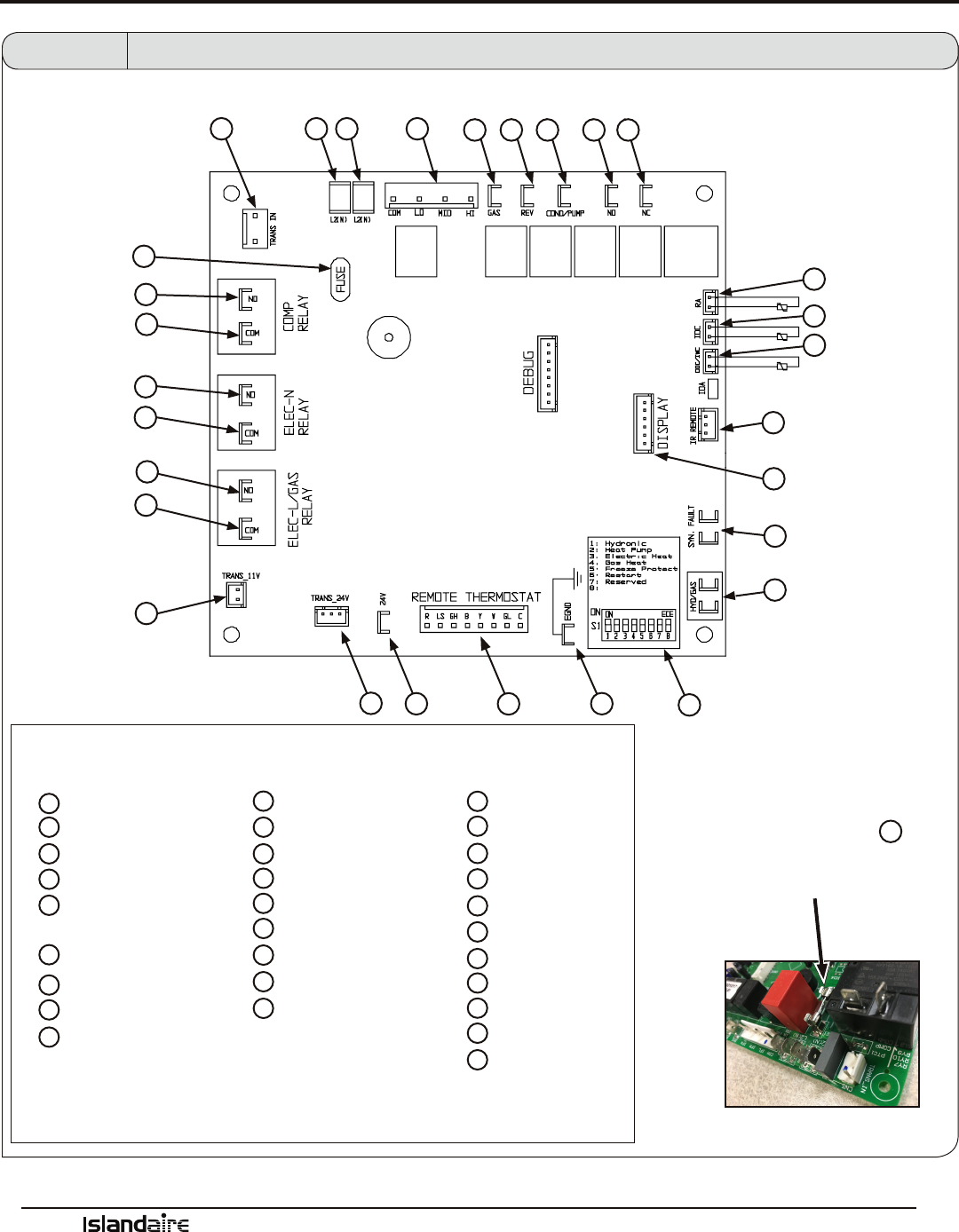

Main Control Board

Fan Con/Cyc for

heating

EGND – ACCESSORY

W

X

Y

Z

AA

BB

CC

HYD/GAS – FAN SWITCH

U T

S R

A

HI

LO

COM

P O N M

C

Q

Fuse

An easily replaceable

8.0 Amp 250V fuse V

is conveniently located

on the control board.

L

J

I

G

F

K

B

A

B

KEY

C

D

E

F

TRANS 24V

24 VAC – ACCESSORY

REMOTE THERMOSTAT

DIP SWITCH - HEAT

CONFIGURATION

G

H

I

J

K

L

M

N

O

P

SYN FAULT

IR REMOTE

ODC/IWC- OUTDOOR COIL SENSOR

IDC – INDOOR COIL SENSOR

RA – RETURN AIR SENSOR

N.C. – NORMALLY CLOSED

N.O. – NORMALLY OPEN

COND – CONDENSER MOTOR

REV – REVERSING VALVE

GAS – GAS VALVE

FAN – EVAPORATOR MOTOR

S

T

U

W

X

Y

Z

AA

BB

CC

L2(N)

L2(N)

TRANS IN

TRANS 11V

N.O. – COMPRESSOR

COM – ELEC_L

N.O. – ELEC_N

Figure 13 Main Control Board

D

E

H

DISPLAY

COM – COMPRESSOR

COM – ELEC_N

N.O. – ELEC_L

V

FUSE

V

Q

R

Manufacturer of Quality Air Conditioning and Heating Products • www.islandaire.com • sales@islandaire.com • (800)-886-2759

33

Performance Specifications

Vertical Packaged

Terminal Cooling Unit

With Heat Pump Or

Electric Heating

PART I: SPECIFICATIONS

Capacities: 9000, 12000, 15000, and 18000 BTUh

PART II: GENERAL

1.01 SYSTEM DESCRIPTION

Single piece, thru-the-wall, electrically-controlled

unit using hermetic rotary compressor for cooling

and heat pump or electric resistance heat.

A. Wall Case:

Shall be entirely constructed of galvanized,

heavy gauge, steel. Wall cases shall be attached

to the wall plenum as shown on plans and shall

have factory provisions for use of appropriate

eld supplied fastening devices to secure the

case to it. In no event shall fasteners be installed

through the basepan in the bottom of the wall

case. Wall case must have dimensions of 23 1/8

in. width by 31 in. height by 23 1/8 in. depth.

B. Outdoor Louvered Grille:

Shall be (stamped)(architectural) anodized

aluminum as show on plans. Louver shall be

(nished natural)(painted) as shown on the

schedule. Louvers shall be easily installed from

the inside of the building aer the cabinet/

wall case has been installed. Special eld fab-

ricated louvers must be approved by the VTAC

manufacturer as to free area and air circulation

requirements. e outdoor grille shall resist cor-

rosion, breakage and match the color specied

on drawing schedule and specications.

1.02 QUALITY ASSURANCE

System shall be tested and certied by ETL. Chassis

capacity and eciency performance shall be certi-

ed in accordance with AHRI standard 390. Chassis

shall meet ASHRAE Standard 90.1 for minimum

energy eciency.

1.03 DELIVERY, STORAGE AND HANDLING

A. e packaging of the chassis shall be sucient to

protect the chassis from damage during ship-

ment via an enclosed truck.

B. Chassis, wall cases/plenums and grilles shall be

shipped in separate cartons. Universal handling

instructions shall be dened and visible on the

cartons from the front, back and sides.

C. Unit shall be stored and handled per manufac-

turer’s recommendations.

Manufacturer of Quality Air Conditioning and Heating Products • www.islandaire.com • sales@islandaire.com • (800)-886-2759

34

Performance Specifications (Cont.)

E. Coils

Condenser and evaporator coils to be construct-

ed of high-eciency, aluminum ns and seam-

less axial-grooved copper tubing, necessary to

achieve EER and COP rating, as specied on the

chassis name plate.

F. Factory-Installed Electric Heater

e factory-installed, open-coil type, electric

heater is standard in heat/cool and heat pump

chassis. e electric heater shall contain both an

automatic reset and a one-shot over temperature

protection device.

e electric heating capacity shall be as identi-

ed on the Contract drawing schedule and in

the specication.

G. Front Panel (supplied with chassis)

Front panel shall be constructed of 18-gauge

galvanized steel to resist breakage and corrosion.

e air lter shall be easily accessible by from

the front of the unit.

H. Fresh Air Vent

e chassis shall have a manual open/close fresh

air vent with a concealed electric switch control.

e vent control shall allow a maximum of

72-75 CFM of fresh air to be drawn into the

room when the indoor fan is operating and the

door is open.

I. Condensate Removal System

e chassis shall have a condensate removal sys-

tem consisting of a condensate suction port, to

draw and atomize condensate, and a slinger ring

integrated in the outdoor fan, to disperse con-

densate onto the condenser coil to be evaporated

during the cooling cycle.

Condensation accumulated during the reverse

cycle heating must NOT be evaporated against

the indoor coil so as to prevent contamination of

the indoor air with pollutants and odors. Con-

densation must be disposed of using a (external)

(internal) drain system as shown on plans.

2.01 EQUIPMENT

A. General

Factory-assembled, single-piece heating and/or

cooling unit. Contained within the unit en-

closure shall be compressor, coils, fans and fan

motor, heating means, controls, all wiring and

piping, and a full refrigerant charge (R-410A).

B. Chassis

e chassis shall be a factory-assembled, single

piece heating and/or cooling unit, that is simple

to install and operate. Just slide the chassis into

a wall case and apply power.

1. Operating Characteristics

Chassis shall be capable of starting and running

at 115 °F ambient outdoor temperature per maxi-

mum load criteria of AHRI Standard 390.

2. Electrical

Chassis shall be equipped with a power cord or

hard wiring ready. e chassis current draw shall

be specied on the chassis nameplate and match

electrical requirements specied on the Contract

drawing schedule and specications. e power

cord plug conguration shall conform to NEMA

standards and the rating shall support the current

draw of the electric resistance heater.

C. Airow System

e airow system shall consist of one perma-

nent split-capacitor, direct-drive permanently

lubricated, two-speed fan motor for the indoor

(EVAP.) and outdoor (COND.) fans. e out-

door fan shall be dynamically balanced, corro-

sion-resistant polymer, multi-blade axial ow

design, with integrated slinger ring. e indoor

fan shall be dynamically balanced, sheet metal,

forward-curved blower wheel, to assure uni-

form air distribution. e fan motor shall be an

enclosed design to reduce the eects of moisture

and corrosion.

D. Compressor and Refrigerant

e rotary-type compressor shall be fully her-

metic with internal and external vibration isola-

tion. e refrigeration system will be sealed and

contain a full refrigerant charge (R-410A).

Manufacturer of Quality Air Conditioning and Heating Products • www.islandaire.com • sales@islandaire.com • (800)-886-2759

35

Performance Specifications (Cont.)

4.01 HEAT PUMP OPERATION

Heat pump units shall have the selected room tem-

perature maintained by cycling either in the heat

pump mode or electric heat. A heat pump unit with

electric heat is switched from the heat pump mode

to electric heat when the unit is on and the outdoor

coil temperature reaches 27 °F, or when the outdoor

air temperature is 35 °F and an initial call for heat is

triggered. At this time, back-up electric heat is the

only source of heat, and will only attempt to go back

to normal compressor operation aer it has been

satised.

A temperature-sensing device shall be used to

monitor the outdoor coil temperature to limit frost

buildup. Defrosting of the outdoor coil will be acti-

vated when outdoor coil temperature drops below

27 °F or outdoor air temperature drops to 35 °F or

less.

For heat pump operation, a room thermostat with

a B (heating changeover) terminal is required. is

will mean that some “auto changeover” thermostats

cannot be used, as many of them either do not have

a B terminal, or energize the B terminal continu-

ously when in the “auto” position.

Condensation accumulated during reverse cycle

heating will NOT be evaporated against the indoor

coil so as to prevent contamination of the indoor

air with pollutants and odors. Condensation must

be disposed of using an external or internal drain

system as shown on plans.

The indoor (EVAP.) fan will stop if the indoor coil

temperature falls below 78 °F. It will restart at its

set speed when indoor coil temperature rises back to

80 °F.

3.01 CONTROLS

All standard models shall be equipped with electro-

mechanical controls to simplify the serviceability of

the unit.

A. Standard Control

e chassis shall have a remote thermostat ter-

minal block to enable interface with a modern

remote wall thermostat.

B. Temperature Limiting

All standard models shall have Temperature Lim-

iting functionality built into the system controls.

e temperature limiting function allows a room

temperature setpoint range to be established, to

avoid extreme temperature settings, to maximize

energy savings.

C. Emergency Heat

Emergency Heat Switch (Heat Pump models

only), upon failure of the compressor, shall

automatically disable the compressor in heating

mode and allow the use of electric heat during

heating cycles. e Emergency Heat Switch is

active at all outdoor ambient temperatures.

D. ermostat

e chassis shall come from the factory ready for

wall thermostat installation.

E. Protection Circuits