Installation & Operation Manual

VPAK LARGE IOM / 95991002_04

NOTE: This manual only applies to VEA 24000 and VHA 18000-24000 BTU/hr models.

For all other A-series models please refer to manual 95991001_05

US

C

VERT-I-PAK

®

A-Series

Single Package Vertical Air Conditioning System

Large Chassis

2

Warnings __________________________________________________________________________________ 3

General

Specications ______________________________________________________________________________ 4

Chassis Dimensions__________________________________________________________________________5

Electrical Data

_____________________________________________________________________________ 6

Air Flow Data

______________________________________________________________________________ 8

Installation

Minimum Clearances ________________________________________________________________________ 9

Installation Overview & Dimensions

___________________________________________________________ 10

Closet View

_______________________________________________________________________________ 11

Rough Opening Dimensions

__________________________________________________________________ 12

Wall Plenum Installation

____________________________________________________________________ 13

Louver Installation

_________________________________________________________________________ 17

Chassis Installation

________________________________________________________________________ 19

Primary Drain Installation

___________________________________________________________________ 20

Return Air & Ductwork Installation

____________________________________________________________ 21

Thermostat Installation

_____________________________________________________________________ 22

Reference

Electrical Wiring Diagram ___________________________________________________________________ 23

Final Installation Checklist___________________________________________________________________ 26

Service and Warranty

_______________________________________________________________________ 27

Diagnostic Error Codes

_____________________________________________________________________ 28

Table of Contents

3

Congratulations!

The Friedrich VPAK has been carefully engineered and manufactured to provide many years of dependable, efcient operation

while maintaining a comfortable temperature and humidity level. Many extra features have been built into the unit to ensure

quiet operation, optimal circulation of cool, dry air, and the most economic operation.

Please carefully read and follow the installation instructions and safety warnings detailed in this manual.

Refrigeration system under high pressure. Do not punc-

ture, heat, expose to ame or incinerate. Only certied

refrigeration technicians should service this equipment.

R410A systems operate at higher pressures than R22

equipment. Appropriate safe service and handling prac-

tices must be used. Only use gauge sets designed for use

with R410A. Do not use R22 gauge sets. Failure to do so

can result in property damage, personal injury, or death.

WARNING

Please read this manual thoroughly prior to equipment

installation or operation. It is the installer’s responsibility

to properly apply and install the equipment. Installation

must be in conformance with the NFPA 70-2008 National

Electric Code or current edition, International Mechanic

code 2009 or current edition and any other applicable local

or national codes.

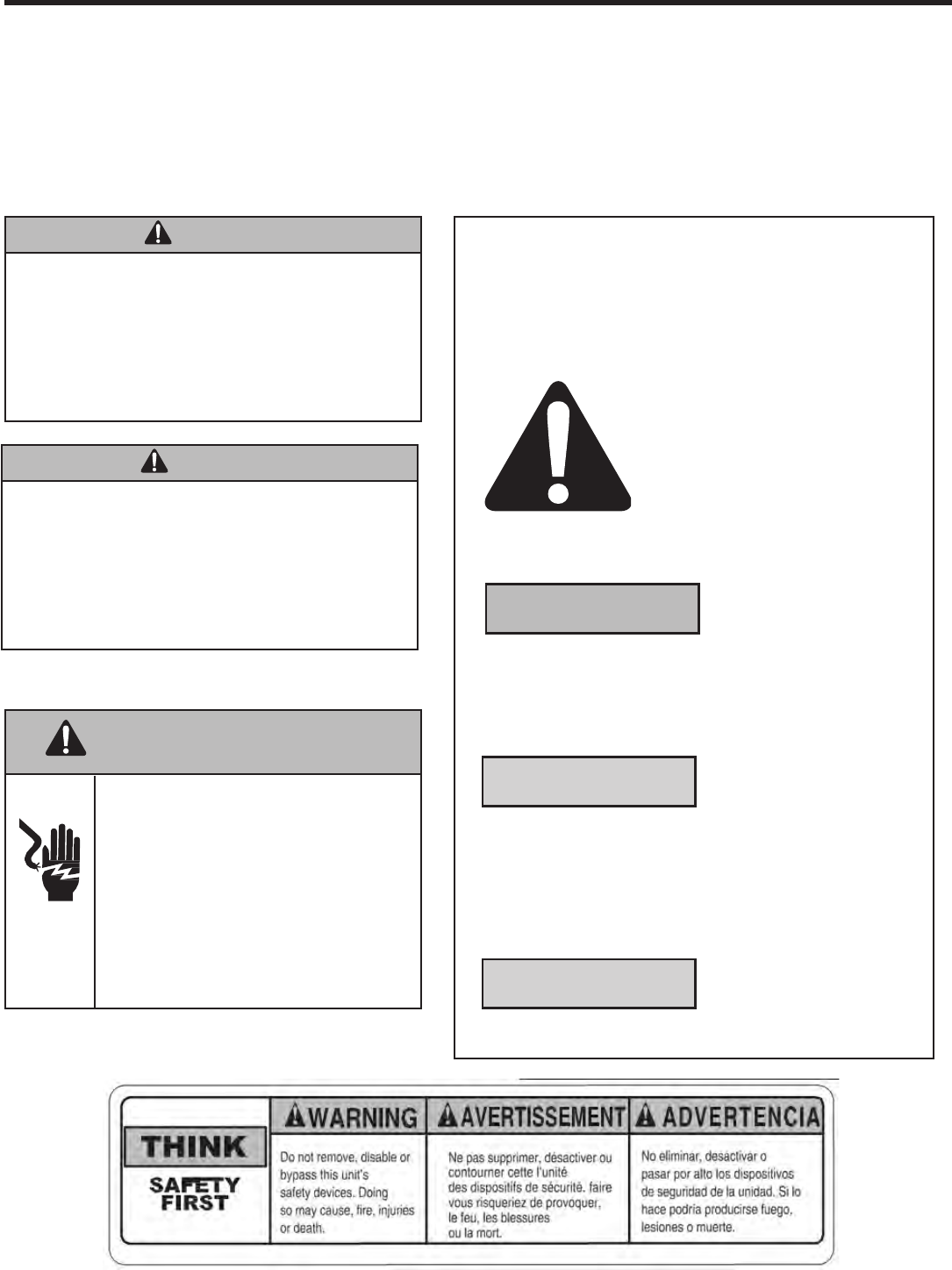

Your safety and the safety of others are very

important.

We have provided many important safety messages in

this manual and on your appliance. Always read and

obey all safety messages.

This is the safety alert symbol.

This symbol alerts you to potential

hazards that can kill or hurt you

and others.

All safety messages will follow the

safety alert symbol with the word

“WARNING” or “CAUTION”.

These words mean:

Indicates a hazard which, if not avoided, can result in

severe personal injury or death and damage to product or

other property.

Indicates a hazard which, if not avoided, can result in

personal injury and damage to product or other property.

All safety messages will tell you how to reduce the chance

of injury, and tell you what will happen if the instructions

are not followed.

Indicates property damage can occur if instructions

are not followed.

WARNING

CAUTION

NOTICE

WARNING

Electrical shock hazard.

Turn OFF electric power before service or instal-

lation.

Unit must be properly grounded.

Unit must have correct fuse or circuit breaker pro-

tection. Unit’s supply circuit must have the correct

wire conductor size. All electrical connections and

wiring must be installed by a qualied electrician

and conform to the National Electrical Code and all

local codes which have jurisdiction. Failure to do so

can result in property

damage, personal injury and/or death.

WARNING

4

General Specications

V E A 2 4 K 3 4 RT P - A

Series

VEA = Cooling + Electric

Heat

VHA = Heat Pump +

Electric Heat

Electric

Heat Size

25 = 2.5 kW

34 = 3.4 kW

50 = 5.0 kW

75 = 7.5 kW

RT = Standard

Remote

Operation

Engineering

Code

Nominal Capacity (Btu /Hr.)

18 = 18000 24 = 24000

Marketing Code

Voltage

K = 230/208 V

R = 265 V *ONLY AVAILABLE ON VHA MODELS

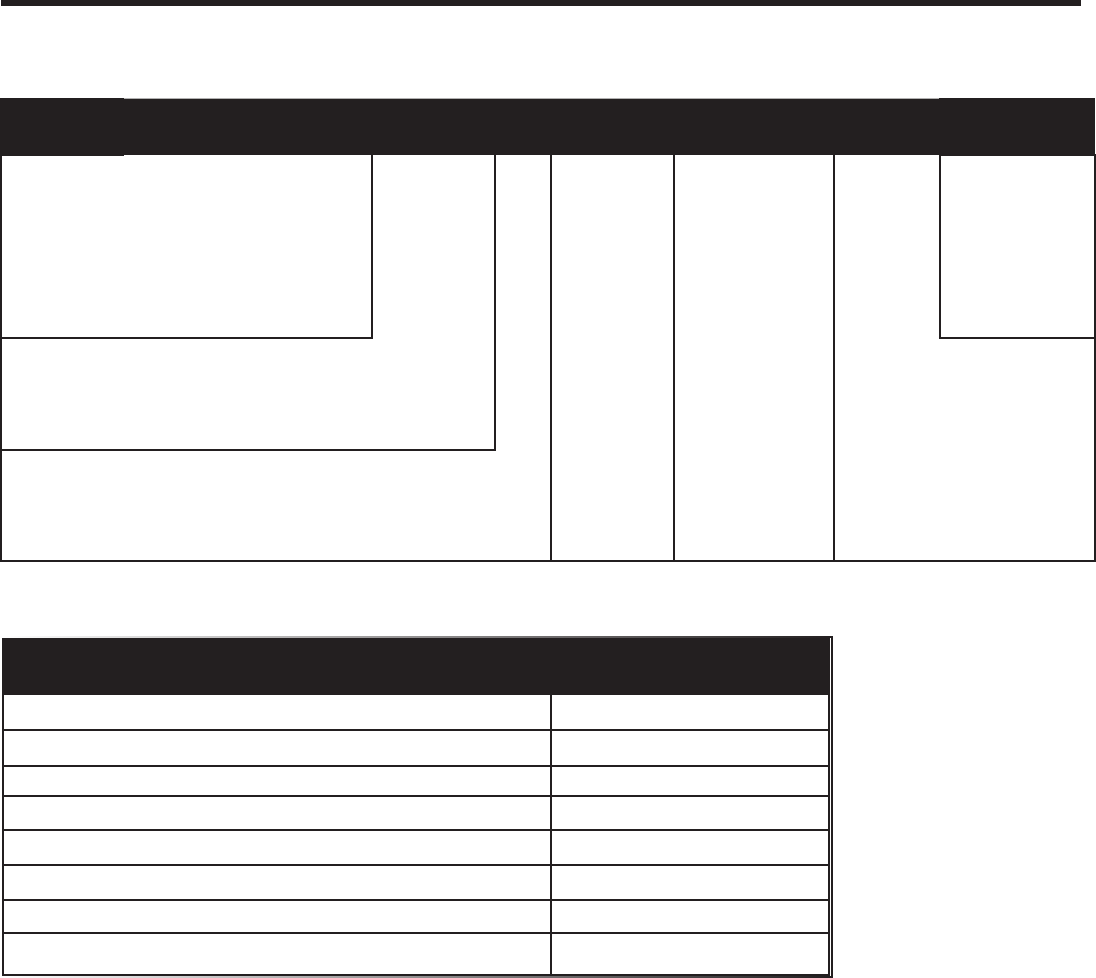

Chassis Specications VEA24, VHA18, & VHA24

Voltage 230/208 or 265

Refrigerant R-410A

Chassis Width 23 1/8”

Chassis Depth 23 1/8”

Chassis Height** 47 1/4”

Shipping W x D x H 26” x 25” x 52”

Supply Factory Collar*** 10”

Drain Connection 3/4” FPT

NOTE:

** Height includes 2” duct collar and isolators under unit

*** Factory collar accepts 10” ex duct

5

Chassis Dimensions

42 5/8

39 3/4

2 3/16

5 1/16

24 3/8

31

11 11/16

47 15/16

22 15/16

2 1/2

10

DUCT

DIAMETER

SUPPLY

AIR

RETURN

AIR

CONDENSER

INLET

AIR

ELECTRICAL

ENTRY

BOTH SIDES

CONDENSER

EXHAUST

AIR

FRONT

SIDE

REAR

TOP

1 1/2

6

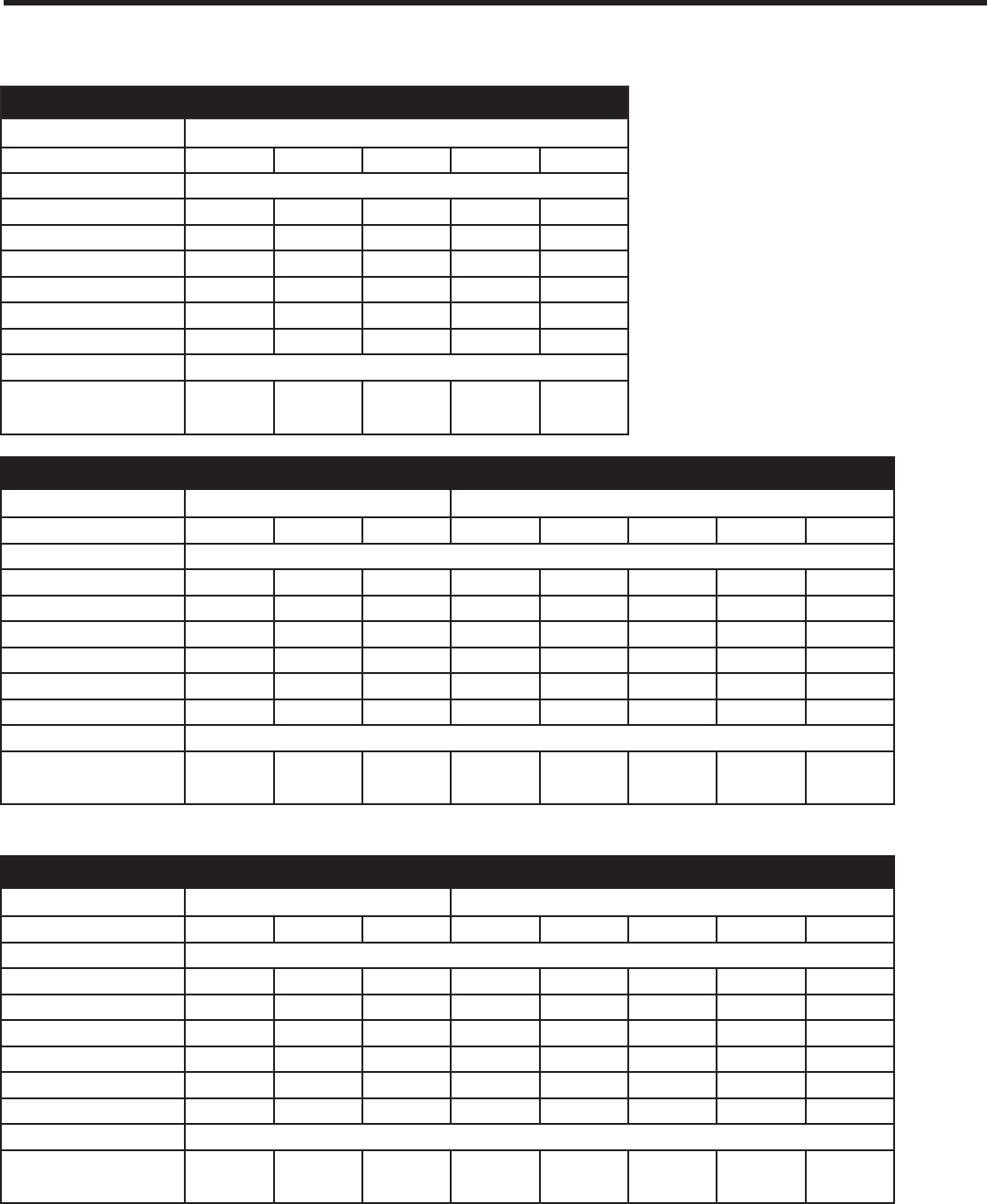

Electrical Data and Specications

VEA 230/208

MODEL VEA24K

Heater Watts

2500/2050 3400/2780 5000/4090 7500/6135 10000/8180

Voltage

230/208

Elec. Heating Current (Amps)

10.9/9.9

14.8/13.4 21.7/19.7 32.6/29.5 43.5/39.3

Minimum Circuit Ampacity

17.2 22.1 30.7 44.3 57.9

Branch Circuit Fuse (Amps)

20 25 35 45 60

LRA - Compressor (Amps)

46.0 46.0 46.0 46.0 46.0

Cooling Current (Amps)

10.0/10.4 10.0/10.4 10.0/10.4 10.0/10.4 10.0/10.4

Basic Heater Size

2.5 kW 3.4 kW 5.0 kW 7.5 kW 10.0 kW

Power Connection

HARD WIRED

Recommended Branch

Circuit Wire Sizes

* AWG-American Wire Gauge

14 12 8 6 4

VHA 230/208

MODEL VHA18K VHA24K

Heater Watts

2500/2050 3400/2780 5000/4090 2500/2050 3400/2780 5000/4090 7500/6135 10000/8180

Voltage

230/208

Elec. Heating Current (Amps)

10.9/9.9 14.8/13.4 21.7/19.7 10.9/9.9 14.8/13.4 21.7/19.7 32.6/29.5 43.5/39.3

Minimum Circuit Ampacity

14.3 19.2 27.8 17.2 22.1 30.7 44.3 57.8

Branch Circuit Fuse (Amps)

15 20 30 25 25 30 45 60

LRA - Compressor (Amps)

42.0 42.0 42.0 46.0 46.0 46.0 46.0 46.0

Cooling Current (Amps)

8.6/9.2 8.6/9.2 8.6/9.2 10.6/10.9 10.6/10.9 10.6/10.9 10.6/10.9 10.6/10.9

Basic Heater Size

2.5 kW 3.4 kW 5.0 kW 2.5 kW 3.4 kW 5.0 kW 7.5 kW 10.0 kW

Power Connection

HARD WIRED

Recommended Branch

Circuit Wire Sizes

* AWG-American Wire Gauge

14 12 10 10 10 10 6 4

VHA 265

MODEL VHA18R VHA24R

Heater Watts

2500 3400 5000 2500 34000 5000 5000 5000

Voltage

265

Elec. Heating Current (Amps)

9.4

12.8 18.9 9.4 12.8 18.9 28.3 37.7

Minimum Circuit Ampacity

12.3 16.6 27.1 12.3 16.6 27.1 38.9 50.7

Branch Circuit Fuse (Amps)

15 20 30 15 20 30 40 60

LRA - Compressor (Amps)

42.0 42.0 42.0 46.0 46.0 46.0 46.0 46.0

Cooling Current (Amps)

7.6 7.6 7.6 9.7 9.7 9.7 9.7 9.7

Basic Heater Size

2.5 kW 3.4 kW 5.0 kW 2.5 kW 3.4 kW 5.0 kW 7.5 kW 10.0 kW

Power Connection

HARD WIRED

Recommended Branch

Circuit Wire Sizes

* AWG-American Wire Gauge

14 12 10 14 12 10 6 4

7

Electrical Data and Specications

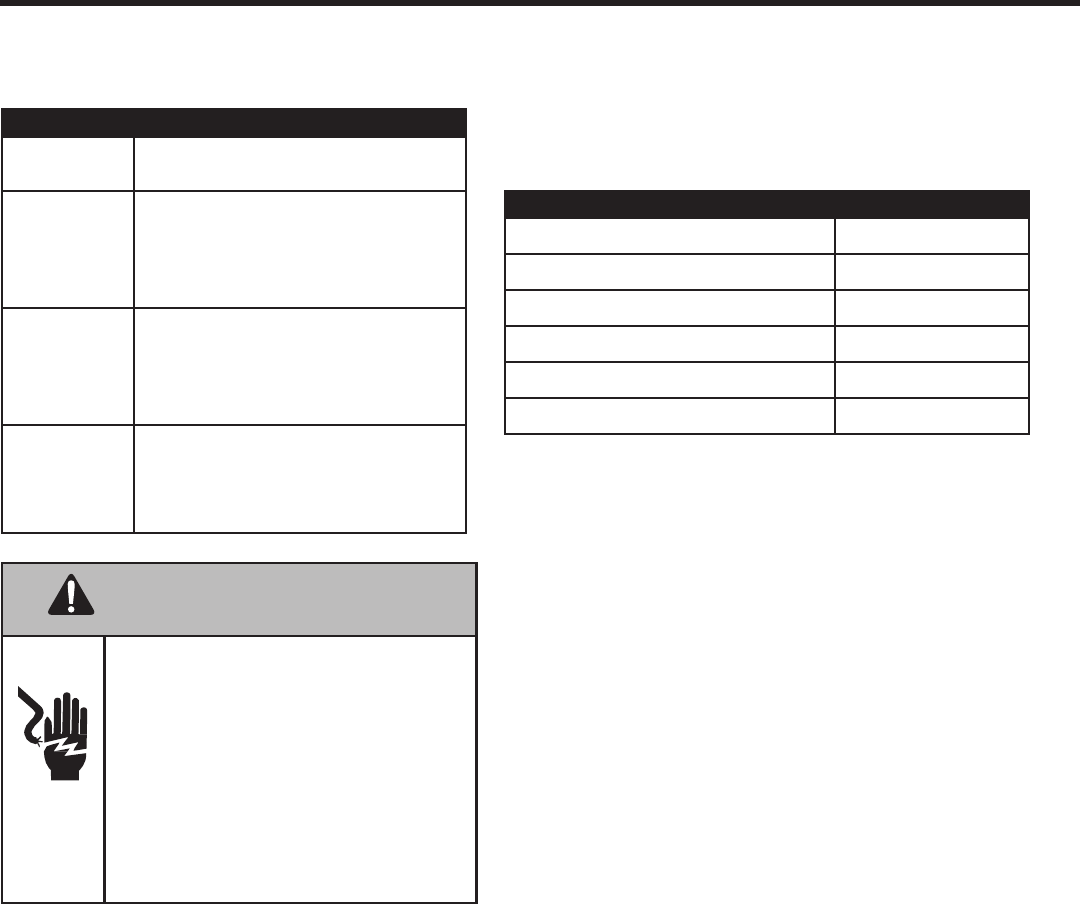

Electrical Requirements

Wire Size Use ONLY wire size recommended for

single outlet branch circuit.

Fuse/Circuit

Breaker

Use ONLY type and size fuse or HACR cir-

cuit breaker indicated on unit’s rating guide.

Proper over current protection to the units is

the responsibility of the owner.

Grounding Unit MUST be grounded from branch circuit

to unit, or through separate ground wire

provided on permanently connected units.

Ensure that branch circuit or general pur-

pose outlet is grounded.

Wire Sizing Use recommended wire size given in tables

and install a single branch circuit. All wiring

must comply with local and national codes.

NOTE: Use copper conductors only.

Electrical Rating Table

NOTE: Use copper conductors ONLY. Wire sizes are per NEC.

Recommended Branch Circuit Sizes*

Nameplate Maximum Circuit Breaker Size AWG Wiring Size**

15A 14

20A 12

30A 10

45A 6

60A 4

AWG - American Wire Gauge

* Single circuit from main box.

** Based on 100’ or less of copper, single insulated conductor at 60˚ C

NOTE: All 230/208 chassis must be hard wired with a properly sized breaker. See unit nameplate for specic electrical requirements.

Use HACR type breakers to avoid nuisance trips. All eld wiring must be done in accordance with NEC and local codes. It is the in-

staller’s responsibility to ensure that the electrical codes are met.

WARNING

Electrical Shock Hazard.

Turn OFF electric power before service or instal-

lation.

Unit must be properly grounded.

Unit must have correct fuse or circuit breaker pro-

tection. Unit’s supply circuit must have the correct

wire conductor size. All electrical connections and

wiring must be installed by a qualied electrician

and conform to the National Electrical Code and all

local codes which have jurisdiction. Failure to do so

can result in property

damage, personal injury and/or death.

8

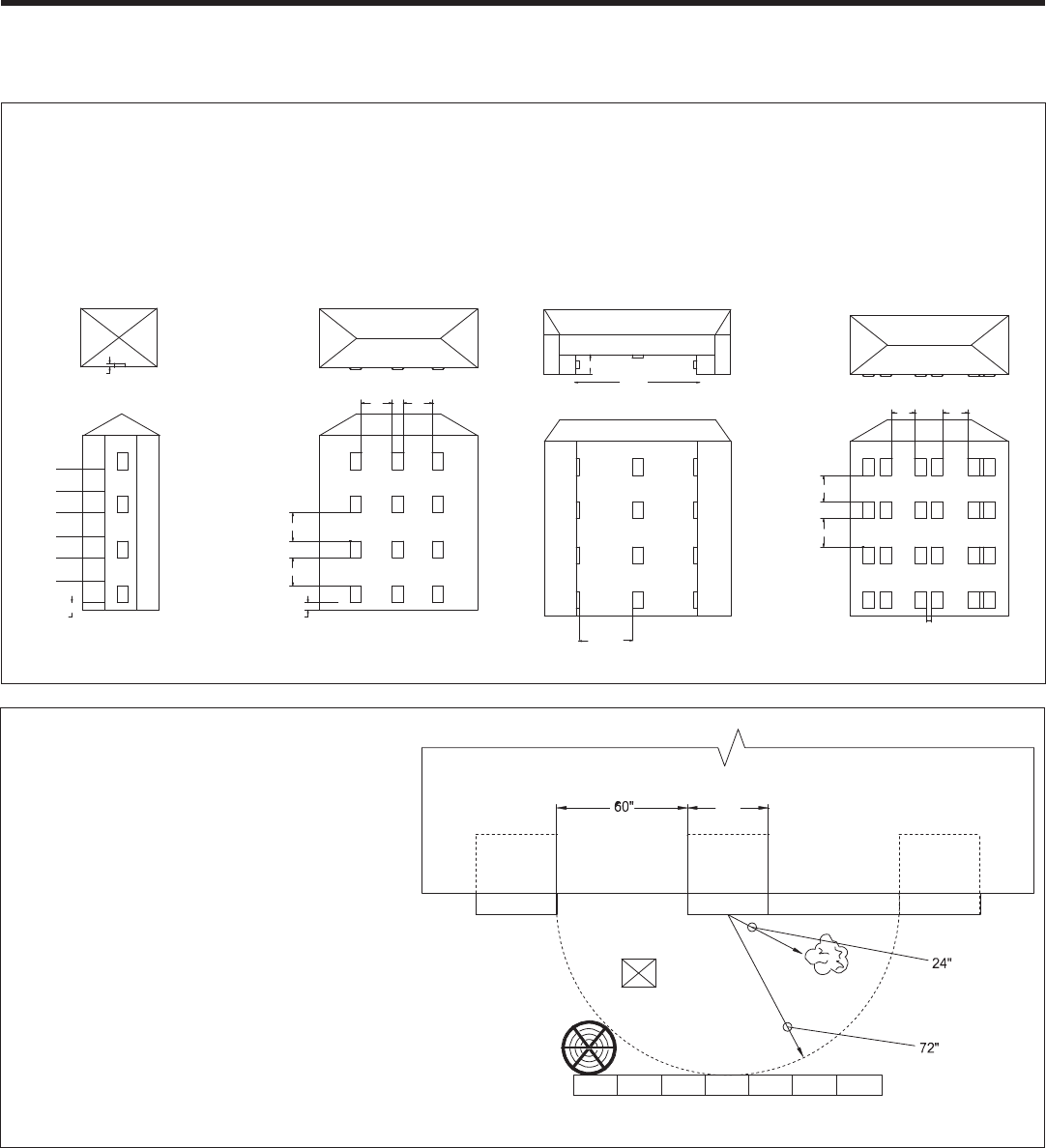

Supply Air Flow Data

Indoor CFM & External Static Pressure

Model

VEA24 VHA18 VHA24

Fan Speed

Low High Low High Low High

ESP (“)

CFM

.10”

610

700 420 465 610 700

.15”

585 670 390 420 585 670

.20”

560 640 345 380 560 640

.25”

535 610 300 325 535 610

.30”

510 580 255 280 510 580

Indoor air ow may be determined by measuring the external static pressure (ESP) of the duct system using an inclined

manometer or magnahelic gauge and consulting the above chart to derive actual air ow. Under no circumstances

should the large chassis Vert-I-Pak equipment be operated at an external static pressure in excess of 0.4” W.C. Op-

eration of the Vert-I-Pak under these conditions will result in inadequate air ow, leading to poor performance and/or

premature component failure.

Control

For LOW speed only operation, connect the fan output terminal from the thermostat to the GL terminal of the electronic

control.

For HIGH speed only operation, connect the fan output terminal from the thermostat to the GH terminal of the electronic

control.

For thermostats with two-speed capability, connect the LOW speed output to the GL terminal and the HIGH speed output

to the GH terminal.

9

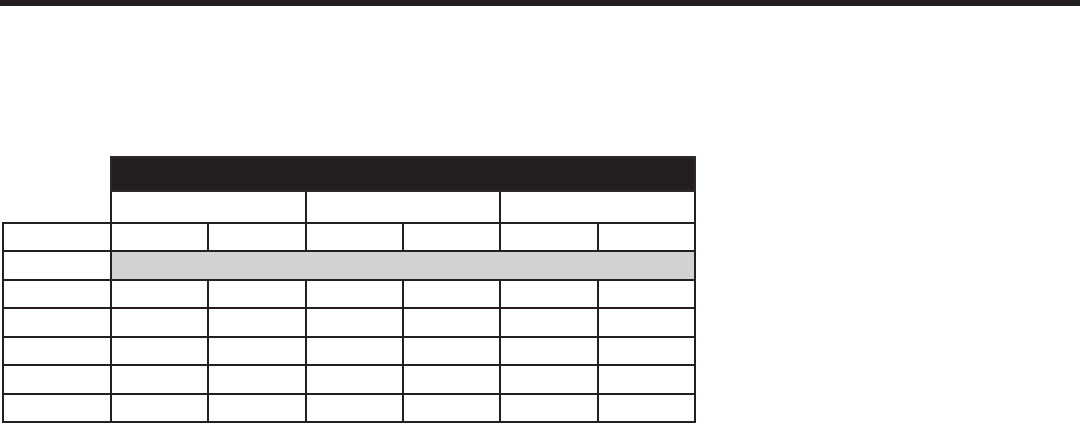

Vert-I-Pak Required Minimum Clearances

6"

60" 60"

60"

60"

60"

60"

60"

60"

60"

6"

6"

12"

60"

60"

64"

160 “

32 “

Figure A Figure B Figure C Figure D

Building Exterior Unit Opening Requirements

VPAK units must be installed on an outside wall. Conned spaces and/or covered areas should be avoided. Units must

be installed no closer than 12” apart when two units are side by side. If three or more units are to operate next to one

another, maintain a minimum of 60” between units or pairs of units (Figure B). If more than two units are sharing a oor

with adjacent, outset units, a minimum distance of 64” must be kept between units (Figure C). Also, a vertical clearance of

60” must be maintained (Figure A) between units. Units installed on the bottom oor must be mounted at least 6” off of the

ground.

Grill Clearance Requirements

Where obstructions are present use the

following guidelines for proper spacing from

the VPAK exterior louvered grill. Friedrich

recommends that ALL obstructions are a

minimum of 72” from the exhaust.

For minor obstruction(s) such as lamp poles

or small shrubbery, a clearance of 24” from

the outdoor louver must be maintained.

For major obstructions such as a solid

fence, wall, or other heat rejecting devices

like a condensing unit, a minimum distance

of 72” must be kept.

BUILDING

24"

POLE

SHRUB

FENCE

MAJOR OBSTRUCTIONS

OUTDOOR

CONDENSING

UNIT

VPAK VPAK

VPAK

The the example pictured above is for reference only and does not represent all possible installations. Please contact Friedrich

Air Conditioning for information regarding effects of other installation arrangements.

10

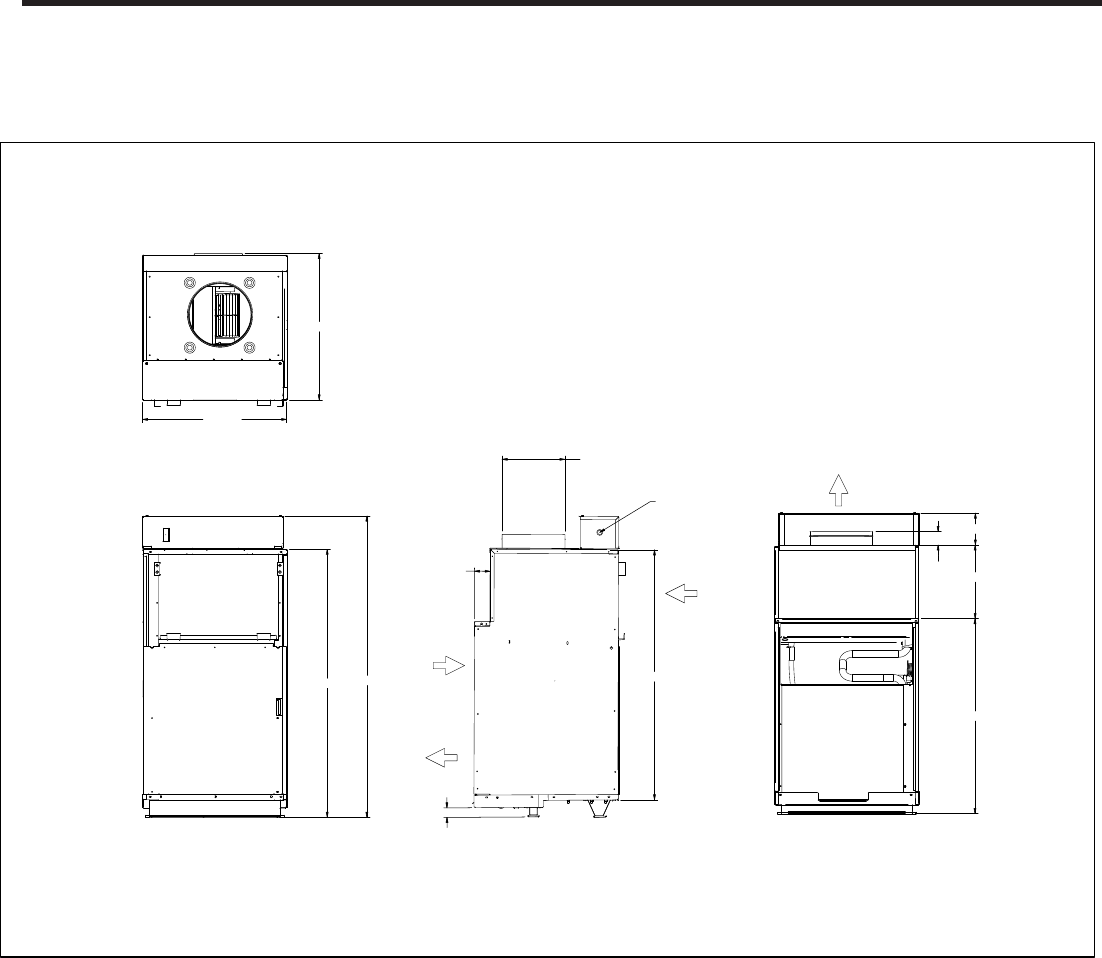

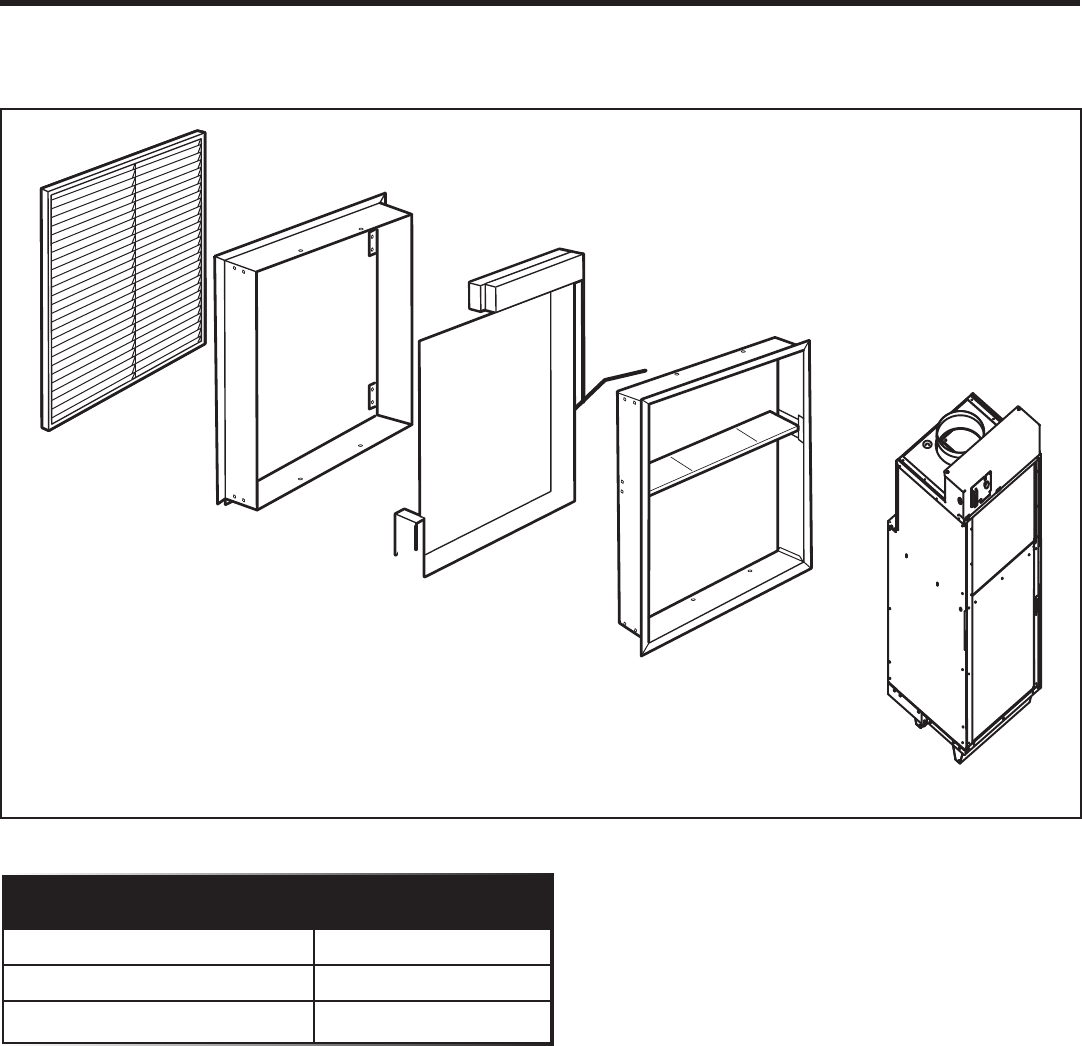

Installation Overview and Dimensional Data

VPAL2

Exterior

Wall Plenum

Exterior

Rough Opening

Interior

Wall Plenum

Chassis

Dimensions

Chassis (W x D x H) 23 1/8” x 23 1/8” x 47 1/4”

Exterior Rough Opening (W x H) 24 5/8” x 30 7/8”

Closet Rough Opening (W x H) 27” x 55 3/4”

11

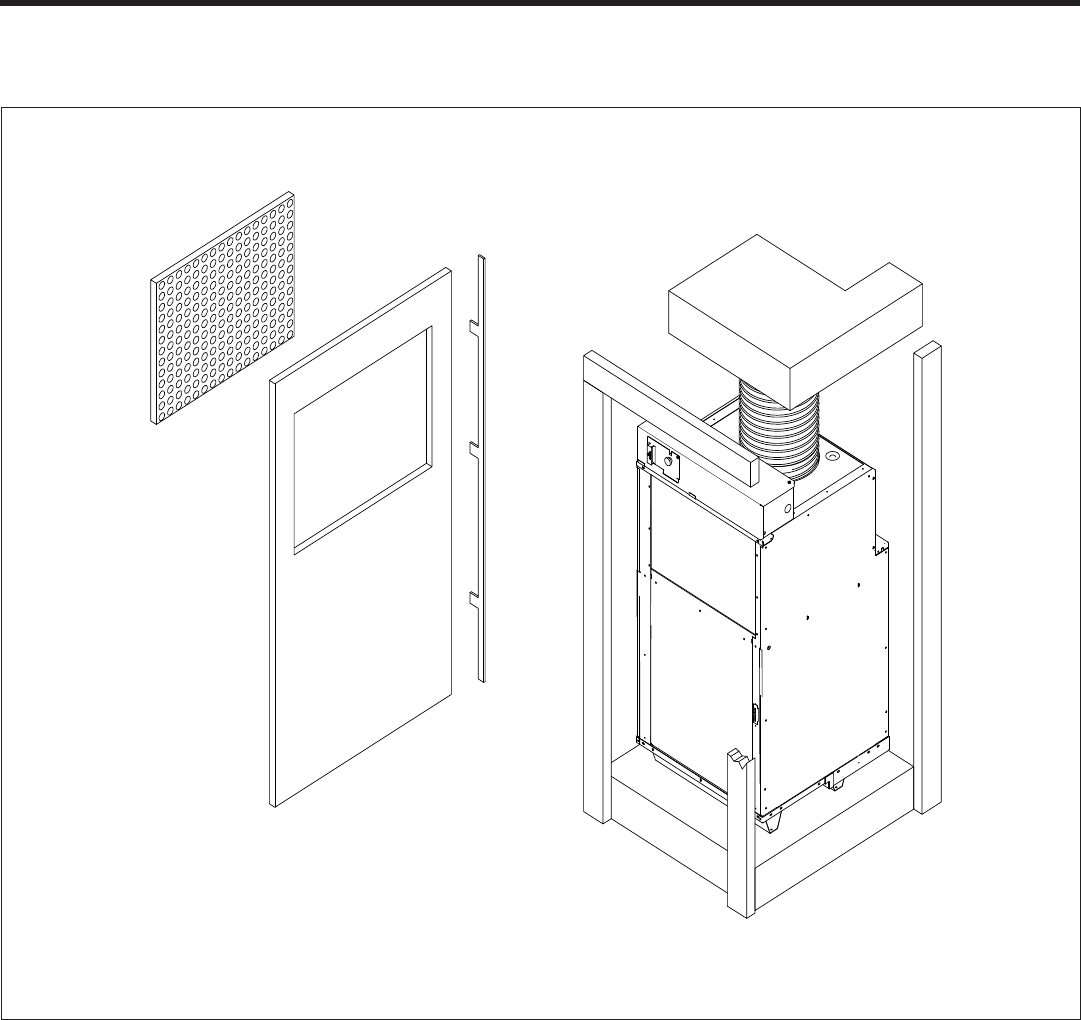

Closet View

Rigid Ductwork

Exterior Wall

Flexible

Ductwork

VPAWPX-XX

Wall Plenum

Minimum 3” clearance on all three

sides required for air ow, service,

and installation

Optional Platform

Electrical

Connection

VPRG4/R Access Panel

and Return Air Grille

Optional 25” x 20”

access panel lter

(eld supplied)

Example Closet

NOTE: It is recommended that 6” of clearance is provided on the side where the primary condensate is plumbed.

12

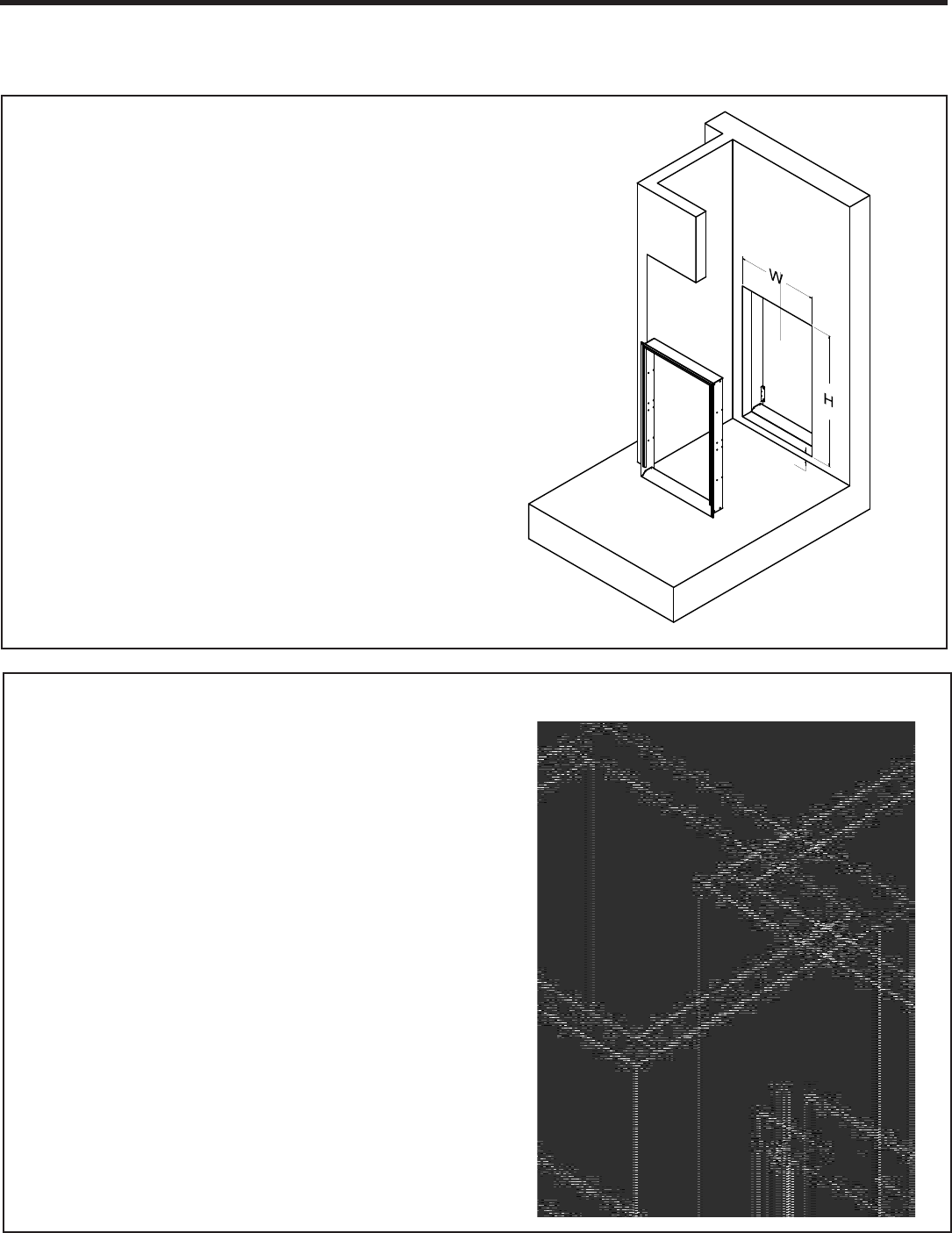

Dimensions (W x H):

27” x 55 3/4”

Dimensions (W x H):

24 5/8” x 30 7/8”

Wall Opening Dimensions

NOTE: The distance between the rough opening and

the nished oor/platform must be 1 1/2”. If the in-

stallation will utilize an auxiliary drain pan it may not

exceed 1 1/2” in height.

1 1/2”

Return Air Access Door Wall Cut-Out

27”

55 3/4”

Exterior Wall Plenum Cut-Out

13

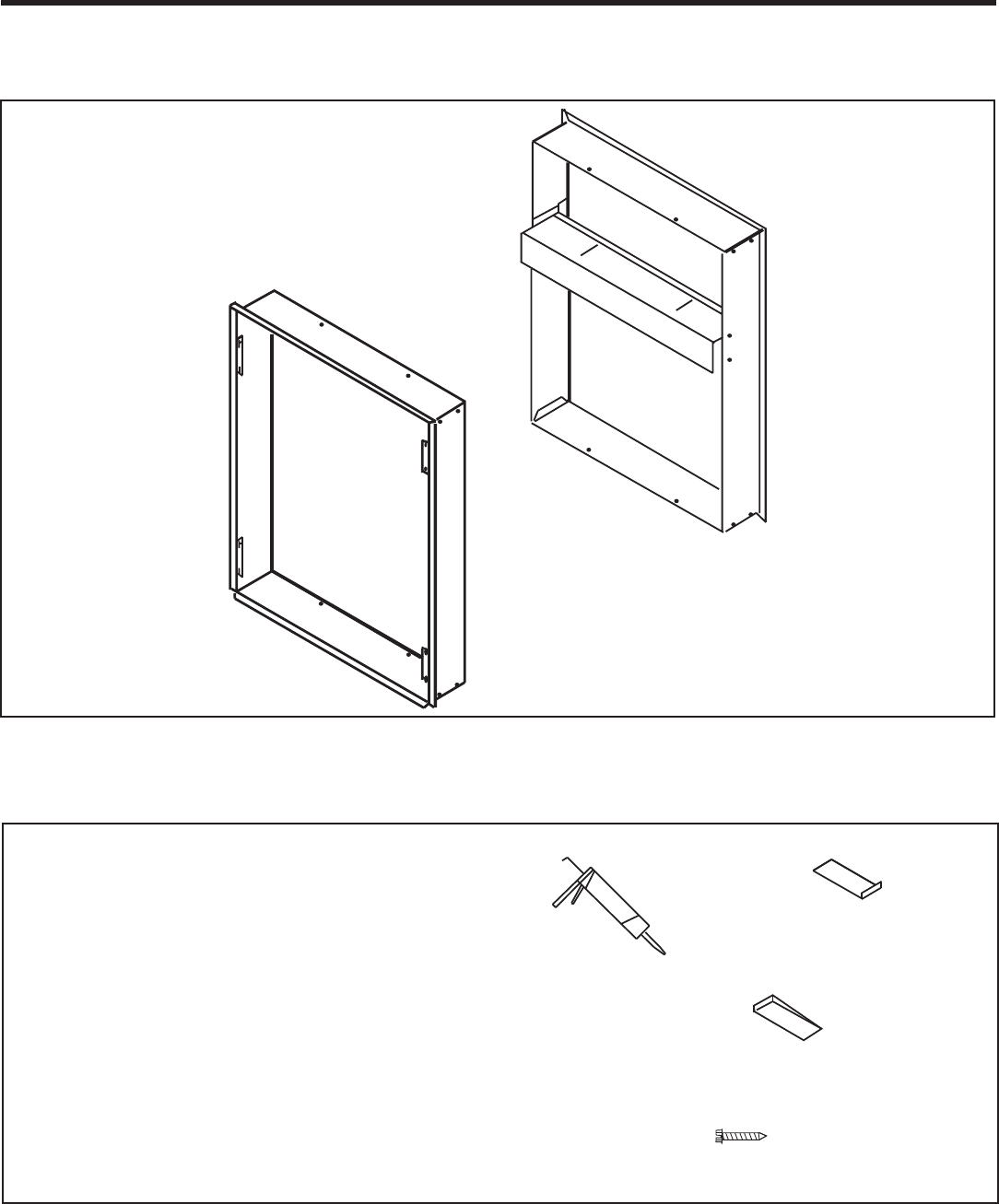

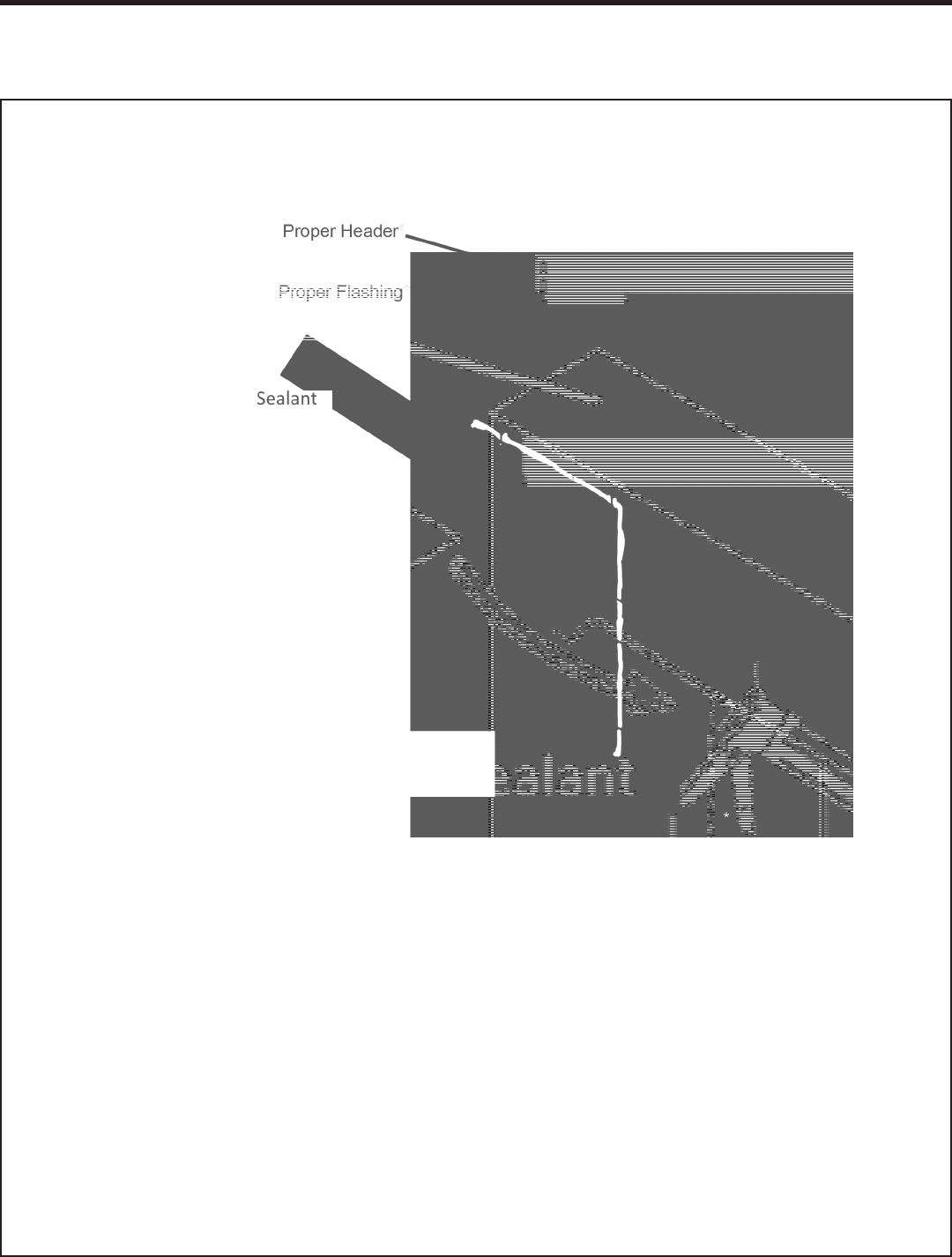

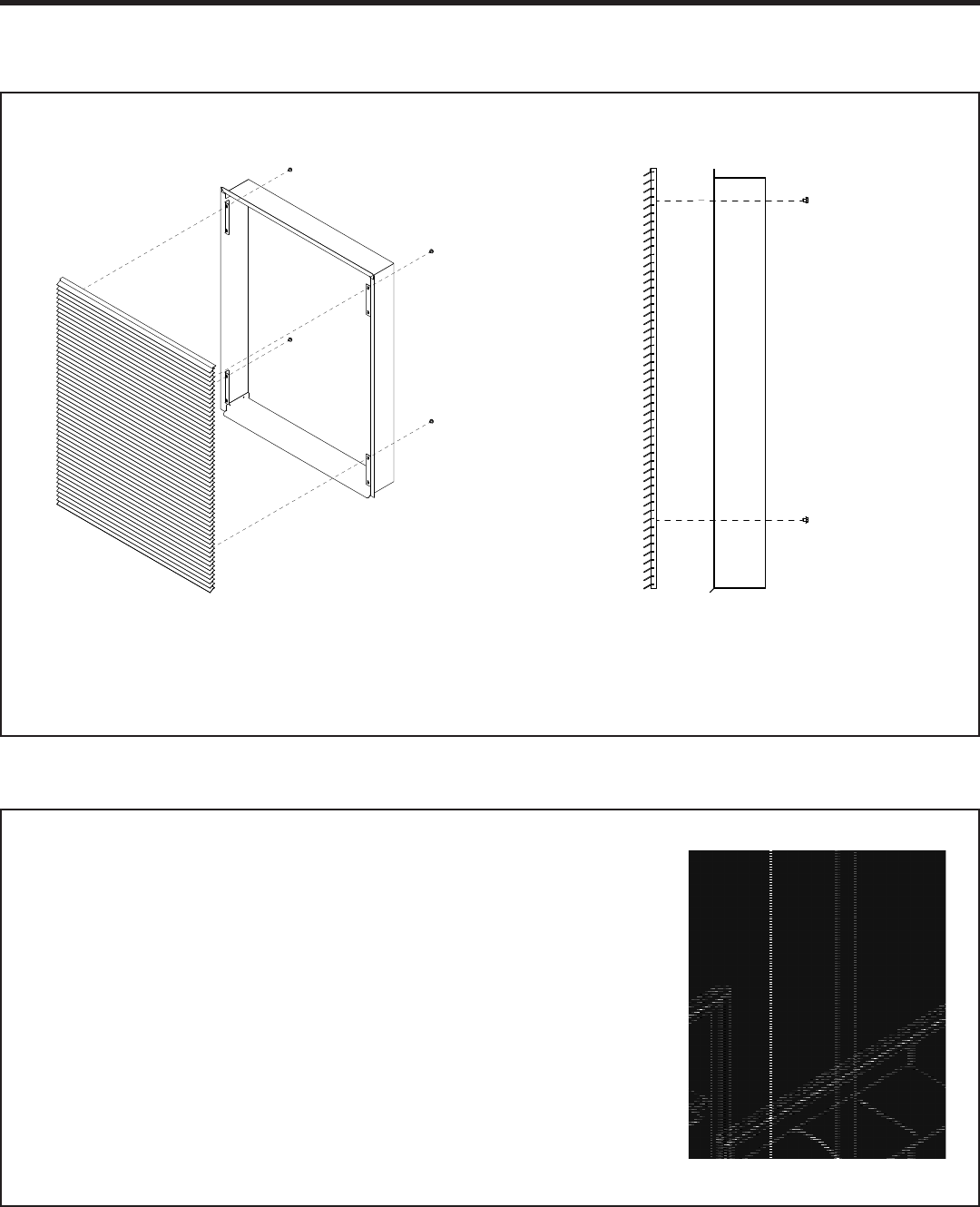

Wall Plenum Installation

A

B

Parts included in Plenum kit:

Outside Plenum Half (Part A)

Inside Plenum Half (Part B)

Field Supplied Parts:

Sealant, attachment screws, and ashing

are eld supplied. Silicone sealant is recommended.

VPAWP-8 adjust for walls up to 4”- 8” thick.

VPAWP-14 adjust for walls up to 8” - 14” thick

All installations are similar.

Flashing

1”-3” screws to at-

tach the plenum

assembly to the wall

studs

Sealant

Shim

14

Wall Plenum Installation

Note: The wall plenum is not designed to carry any structural load. A load bearing header must be built above

the rough opening.

1. Prepare the rough opening. The rough opening should be lined with metal or wood. The plenum will warp if

sealed against concrete or brick.

2. Dry t the outside plenum half into the rough opening and check the t and level.

3. Remove the outside plenum half, ash the rough opening to ensure proper t and level.

4. Pre-installing the exterior louver (VPAL2) as shown above is optional (See Page 17).

5. Apply sealant to the outside plenum half and insert into the rough opening to ensure a water-tight seal.

Ensure that the outside plenum half is securely attached to the framed opening.

Step 1 - Outside Wall Plenum Half

15

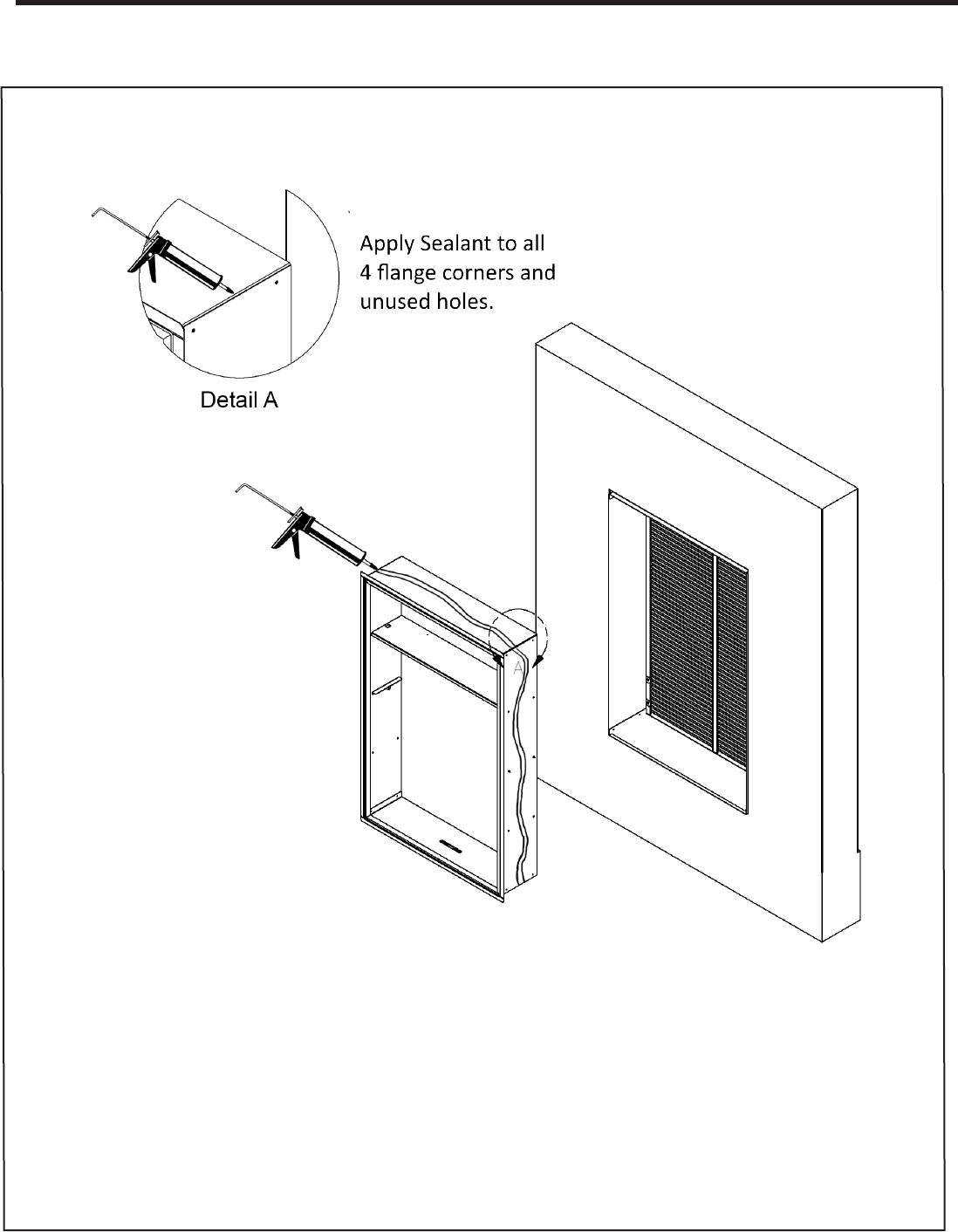

Wall Plenum Installation

Step 2 - Inside Wall Plenum Half

Caulk all 8

Flange Corners

and Unused

Holes

Detail A

1. Apply sealant to all 4 ange corners and unused holes. See Detail A.

2. Flash the inside of the rough opening to ensure the proper t and level.

3. Insert inside plenum half (Part B) into outside plenum half (Part A). Ensure that Part A does not back out of

the rough opening.

4. Remove the inside plenum half.

5. Apply sealant to the outside plenum half and insert into the rough opening to ensure a water-tight seal.

16

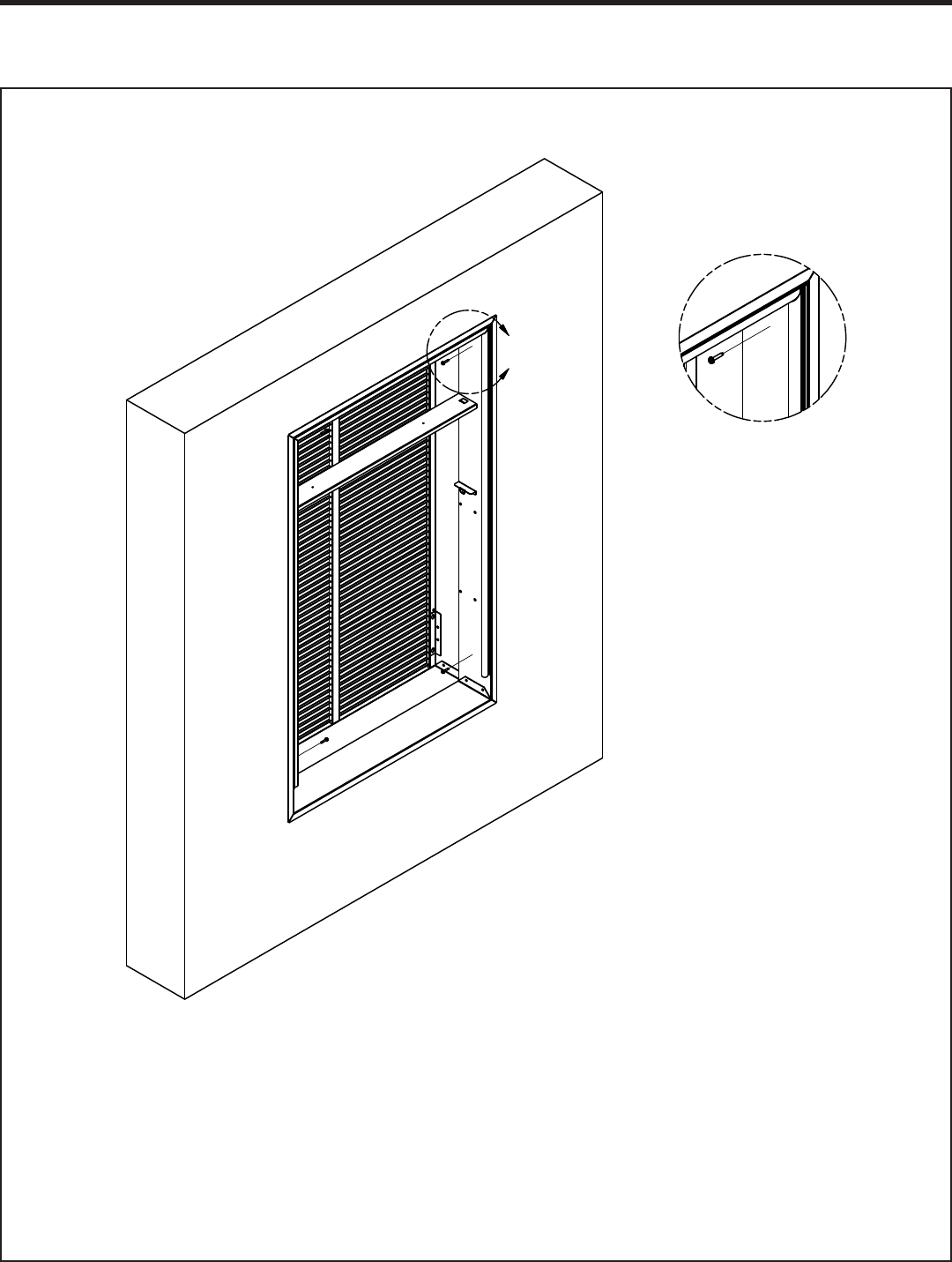

Wall Plenum Installation

B

Detail B

Step 3 - Inside Wall Plenum (cont.)

NOTE: Do not place any screws, fasteners, or penetrating holes through the top or bottom of the plenum

assembly.

1. Drill pilot holes on the interior of the inside plenum half (Part B) as show in Detail B. Pilot holes should be

located approximately 4” from the top and bottom of the inside plenum half, on both the left and right sides.

2. Install fasteners through each pilot hole. Fastener must pass through both Part A and Part B. If the inside

and outside plenum halves do not overlap at fastening point, be certain to drill extra holes where needed to

secure both Part A and Part B to the rough opening.

17

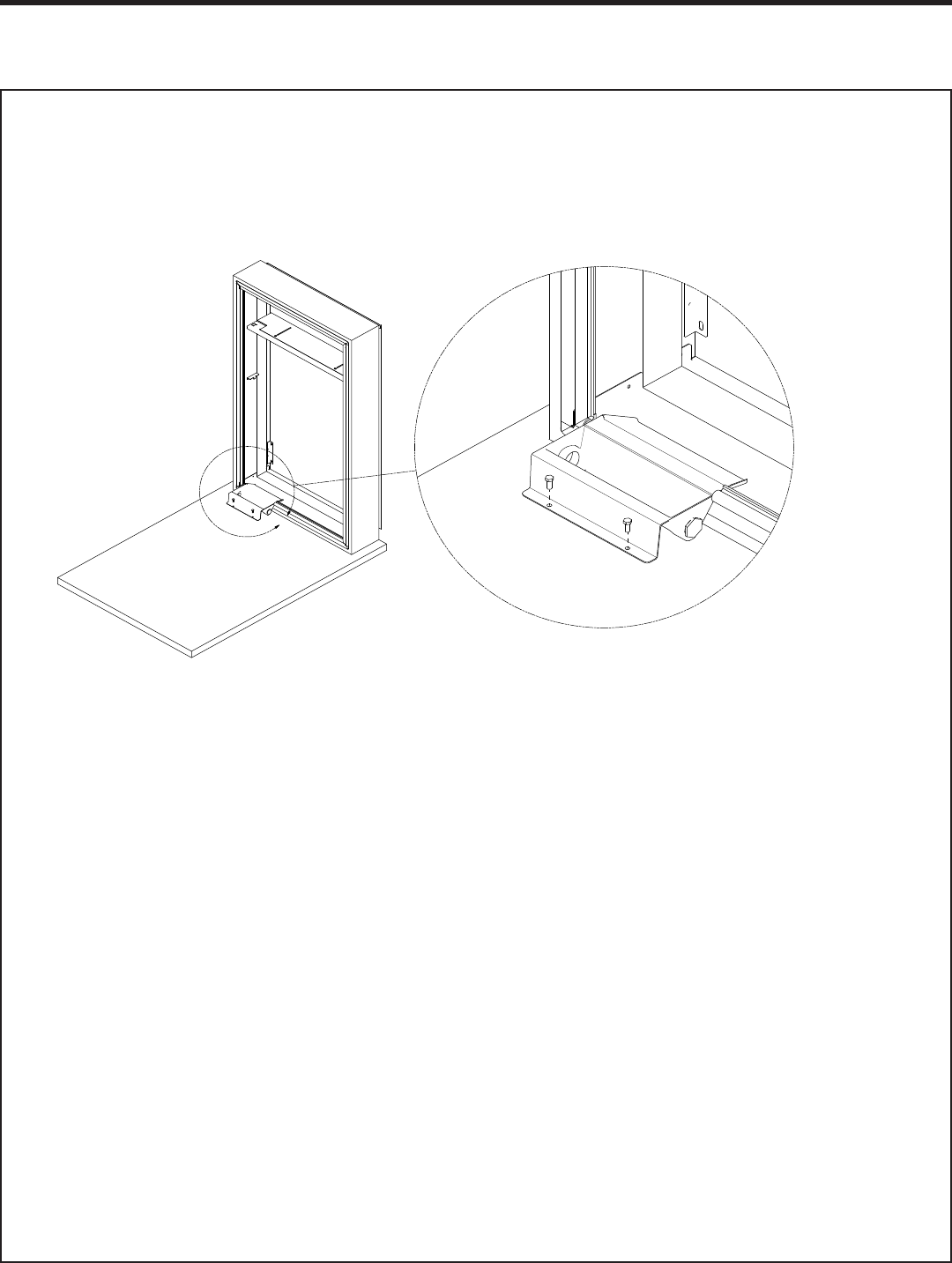

Drain Kit Installation

A

Step 4 - VPDP1 Installation

NOTE: VPDP1 (Drain Kit) should be installed prior to the installation of the chassis.

1. Cut the weather seal gasket at the left corner of the plenum.

2. From the initial cut, measure 8” toward the center of the plenum and make a second cut.

3. Peel away the cut section of gasket from the plenum surface.

4. Run a 1/4” bead of sealent the entire width of the removed gasket.

5. Insert the drain kit with the overow lip toward the plenum and ensure it is ush.

6. Finish installation with the eld supplied parts.

18

Louver Installation

Installation of the louver PRIOR to wall plenum installation

1. Hold the louver up to the outside plenum half (Part A) and line up the louver top with the very top edge of the ¾”

ange.

2. Line up the wall plenum holes with the threaded holes in the louver and securely tighten fasteners.

Installation of the louver AFTER the installation of wall plenum on

elevated oors

From the interior of the utility closet:

1. Tie a rope or tether to the architectural louver and the divider in

the wall plenum to prevent it from falling if dropped.

2. Turn the louver sideways and push the louver out below the

divider in the wall plenum.

3. Pull the louver back against the wall plenum and align the holes.

4. Insert and tighten all eight provided fasteners. When the louver

is secured, remove the safety tether.

19

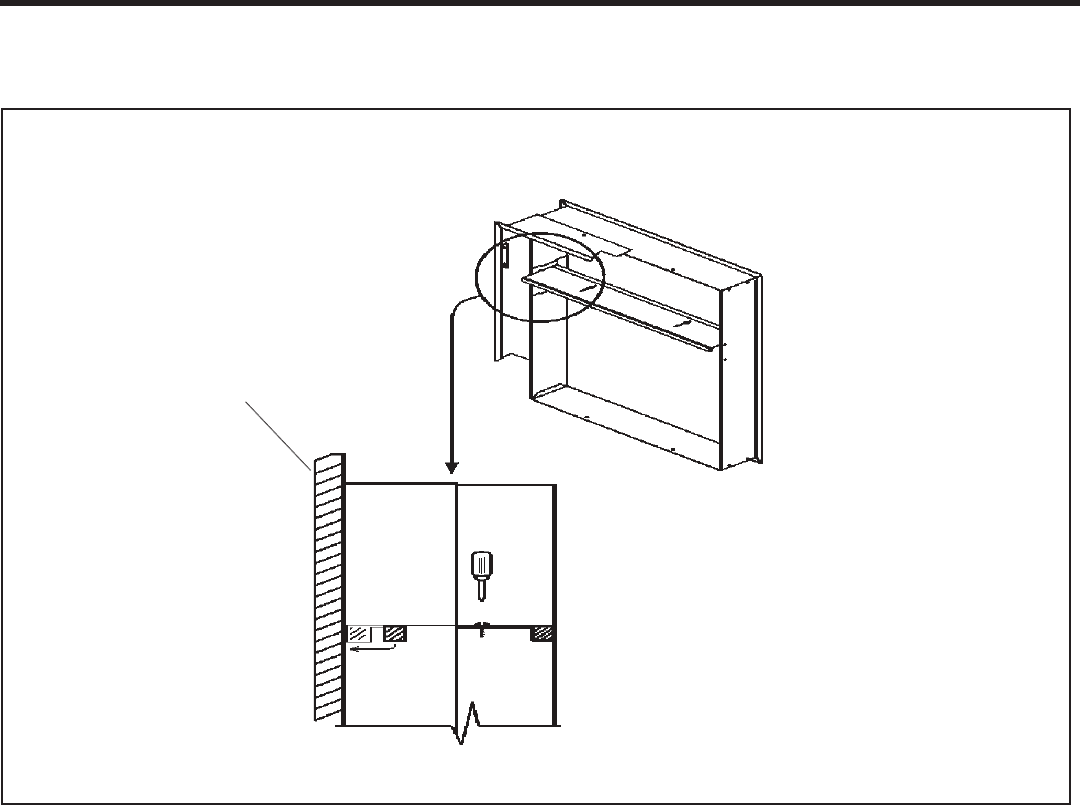

Final Wall Plenum and Architectural Louver Installation

NOTE: Ensure that the weather strip is undamaged and provides a continuous

seal around the inner perimeter of the plenum.

Apply silicone grease or other non-petroleum-based lubricants to the weather strip to enhance the sealing

capability of the weather strip and ease installation of the air conditioner chassis.

1. Loosen the two set screws located on the top side of the divider.

2. Slide the top part of the divider toward the outside until the sealing strip makes contact with the exterior

louver.

3. Tighten the set screws to complete the adjustment.

NOTE: Let all ashing cure completely before installing the chassis.

Louver

20

A

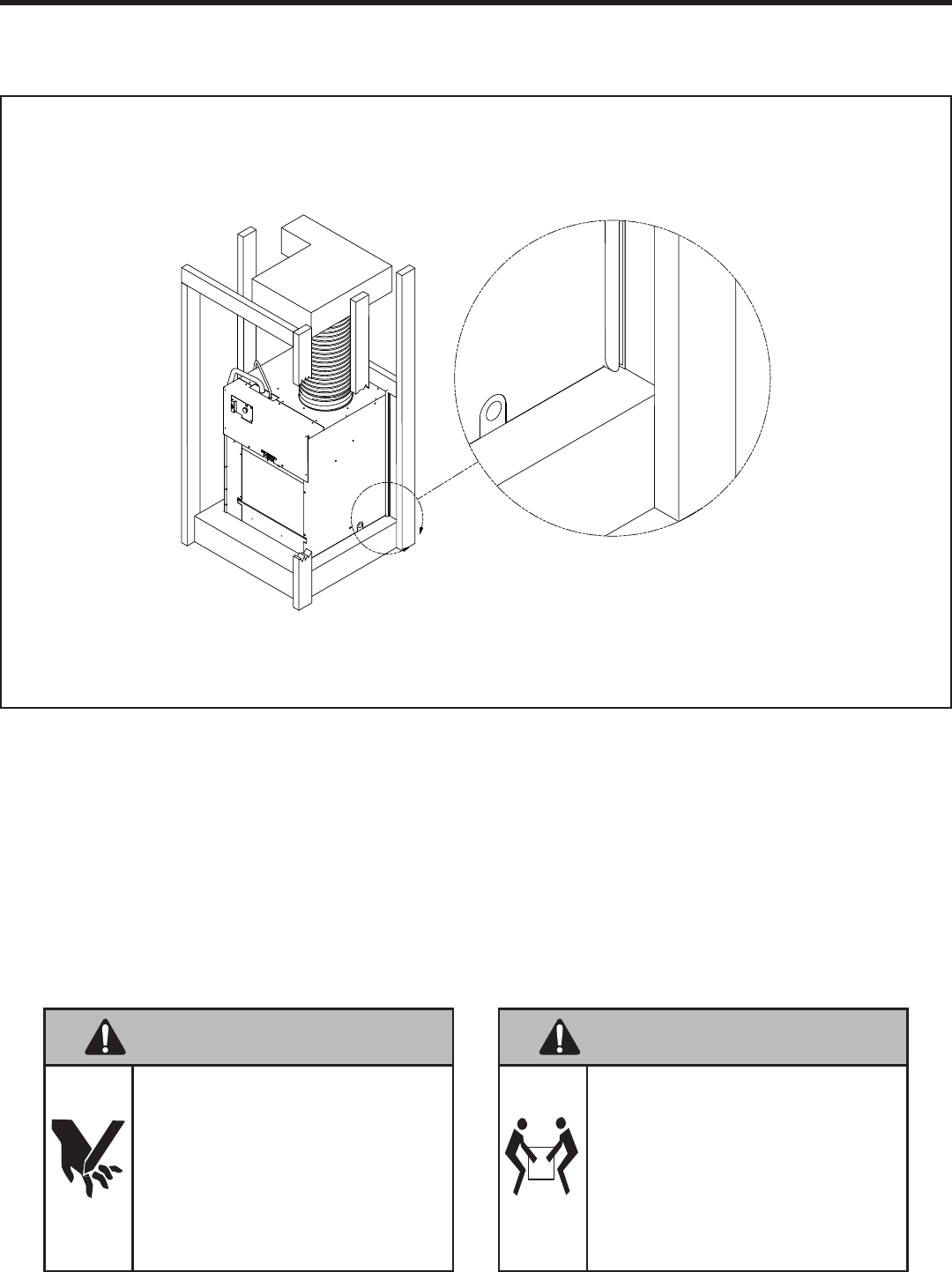

Chassis Installation

CAUTION

Excessive Weight Hazard

Use two or more people when installing your air

conditioner.

Failure to do so can result in back or other injury.

CAUTION

Cut/Sever Hazard

Some edges may be sharp.

Use gloves or other hand protection when han-

dling the unit.

Failure to do so can result in minor to moderate

personal injury

1. Ensure that the wall plenum and louver are installed in accordance with the instructions listed on pages 13-18.

2. Place the chassis into the closet with the outdoor side facing the wall plenum opening.

3. Slide the chassis into the wall plenum until the plenum divider seal is established.

NOTE: The Vert-I-Pak chassis must be inserted into the wall plenum so that the plenum divider gasket makes contact with

the plastic condenser bafe on the unit. The chassis will t approximately 2 3/8” into the wall plenum.

21

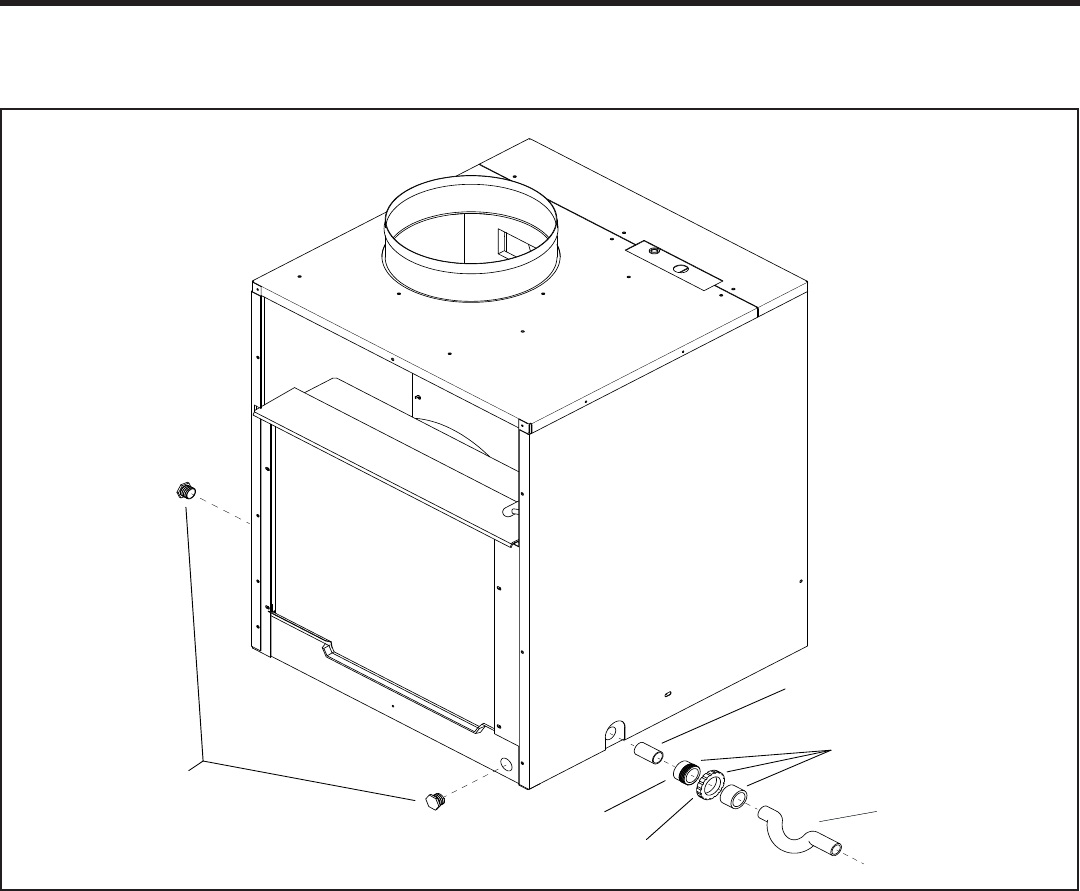

Nipple 3/4” PVC/NPT

Union 3/4” FTP/SLIP

Example of field

supplied DWV system

Threaded end

Slip end

Supplied 3/4” plugs

Primary Drain Installation

NOTE: Failure to follow the following procedures may result in serious property damage. A eld supplied secondary con-

densate pan or P-trap may be required. Check with local codes. In case of drainage system blockage, the unit base will

allow excess water to ow out of the unit through the plenum and the architectural louver. It is critical to ensure that the

drainage path is not blocked or obstructed in any way during installation.

1. The supplied drain kit must be connected to one of the two 3/4” FPT connections on the VPDP1.

2. Insert the provided 3/4” nipple into the determined connection using eld-supplied Teon tape or pipe joint

compound.

3. With the slip end of a 3/4” union, connect to the nipple with Teon tape or pipe joint compound.

4. Hand-tighten all ttings to prevent damage to unit or ttings.

5. Install a eld-supplied drain system to the slip end of the union. A trap is recommended and drain connections

should be connected to building DWV system. Pitch the drain line of a 1/4” downward slope for every foot (1’) of

lateral horizontal run to the DWV.

6. Plug the unused connection port on the VPDP1 with the provided 3/4” pipe plug with eld-supplied Teon tape or

pipe joint compound. Hand tighten to prevent damage to the unit or ttings. Do not thread metal or copper pipe

ttings directly into unit.

7. Check the system for leaks.

22

Indoor Return Air Grille and Ductwork Installation

Option 1 Option 2

VPRG4/R Return Air Grille with Access Panel

A eld-supplied (25” x 20”) can be mounted inside

the hinged access door. The door can be installed

with the grille oriented at the top of the panel for

improved sound attenuation.

NOTE: All Vert-I-Pak chassis are shipped with a 20” x 14” lter installed. If a different lter holder or location is to be used,

the lter on the chassis MUST be removed.

Ductwork

The supply duct system should be designed using a recognized method such as the equal fraction or velocity reduction

method, using the appropriate duct calculator(s) for the type(s) of duct being used in the system. The duct system should

be designed for a maximum friction rate of .3” water column taking into consideration all ttings, registers and/or diffus-

ers.

NOTE; Do not operate the unit without a supply duct attached. The return air to the Vert-I-Pak unit MUST NOT be ducted

and all units must have a free return air conguration to perform properly.

Field Supplied Return Air Grille

A eld supplied return air grille divorced from the

access panel must have a minimum 250 square

inches of free area.

23

Remote Thermostat

All Friedrich Vert-I-Pak units are factory congured to be

controlled by using a single stage heat/cool remote wall

mounted thermostat. The thermostat may be auto or

manual changeover as long as the control conguration

matches that of the Vert-I-Pak unit.

To connect the wall mounted thermostat:

1. Pull the disconnect switch.

2. Unscrew and remove the control box panel.

3. Select which side to run your thermostat wire.

4. Run the wires through the side hole in the box to

reach the connection terminal wiring.

5. Make the connections, appropriately matching the

wires as shown in the wiring diagram.

6. Reattach the control box cover.

Front Desk Control Terminals

The Friedrich Vert-I-Pak has built-in provisions for con-

nection to an external switch to control power to the unit.

The switch can be a central desk control system door

switch.

For desk control operation, connect on side of the switch

to the D1 terminal and the other to the D2 terminal.

When the circuit is closed, unit operation will stop.

NOTE: The desk control system and switches must be

eld supplied.

Maximum Wire Length for Desk Control Switch

Auxiliary Fan Control

The Friedrich Vert-I-Pak also has the ability to control a

24VAC relay to activate an auxiliary or transfer fan. The

outputs are F1 and F2 on the control board.

To connect the relay, simply wire one side of the relay to

F1 and the other side to F2.

NOTE: The relay and auxiliary fans must be eld sup-

plied. The relay must be 24VAC @ 100mA or less.

Interface Denition

NOTE: It is the installer’s responsibility to ensure that all

control wiring connections are made in accordance with

the installation instructions. Improper connection of the

thermostat control wiring and/or tampering with the

unit’s internal wiring can void the equipment warranty

and may result in property damage, personal injury, or

death. Questions concerning proper connections to the

unit should be directed to the factory.

Remote Thermostat and Low Voltage Control Connection

AWG Wire Size Maximum Length (ft.)

24 400

22 600

20 900

18 1500

16 2000

Terminal Code Wire Connection Function

C Common Ground Terminal

GH Call for High Fan

GL Call for Low Fan

B Call for Heat Pump (Reversing Valve)

Y Call for Compressor

W Call for Heating (Electric)

R 24VAC to Wall Thermostat

24

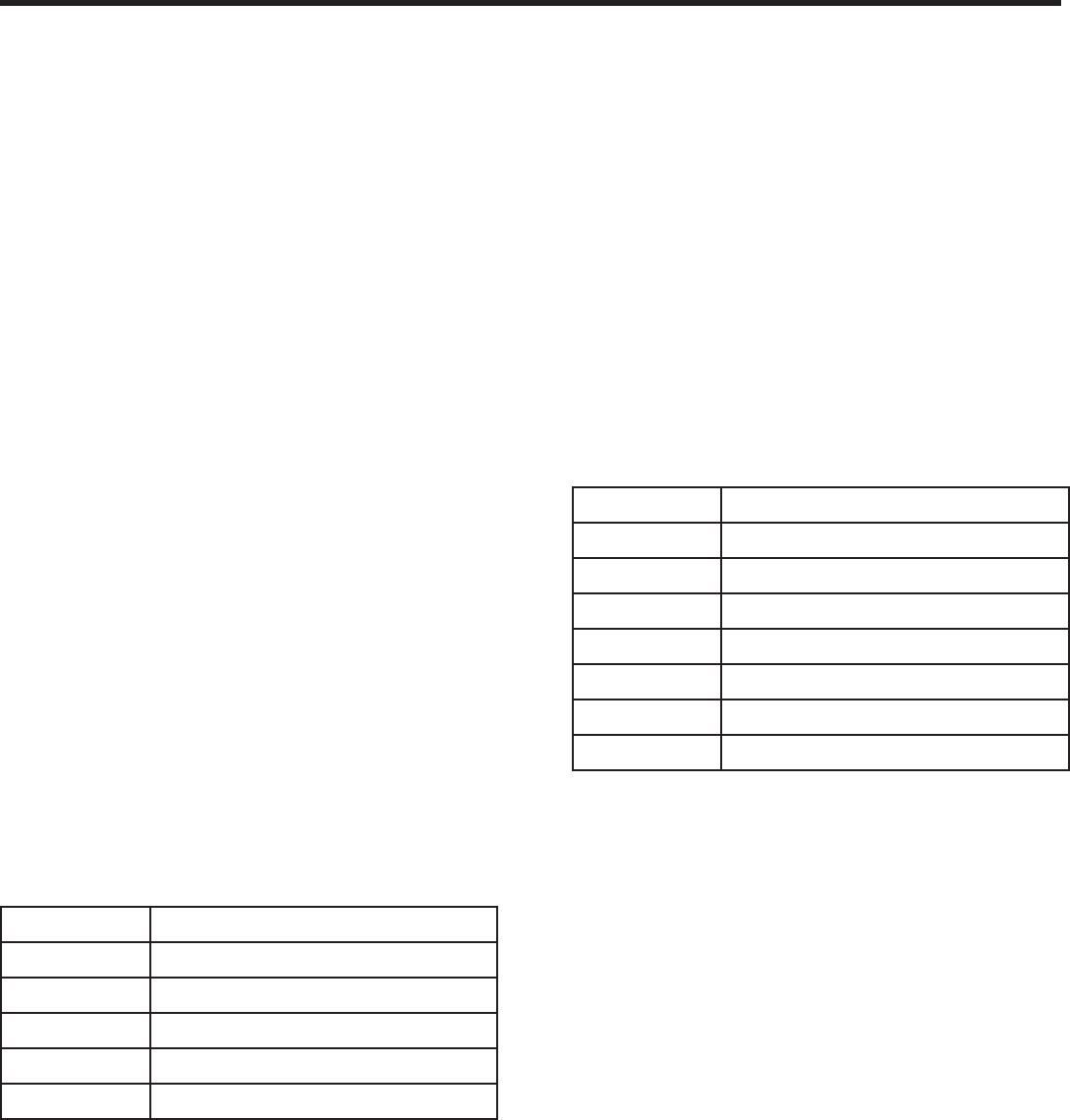

VEA 230/208 Electrical Wiring Diagram

B

L

U

E

RED

WHITE

WHITE

GREEN

BROWN

ORANGE

C

H

E

R

M

F

A

N

L1

L2

ELECTRONIC CONTROL

"

F

"

R

S

C

TERMINAL DETAIL

BLACK

B

L

A

C

K

BLUE

HEATER

2.5 KW & 3.4 KW

5.0 KW

BLACK (TO L1)

RED

QUICK

DISCONNECT

CAPACITOR

BLOWER

MOTOR

TO MOTOR

MOUNT

W

H

IT

E

5

2

0

(

T

O

L

2

)

COMPRESSOR

GASKET

TEMINAL COVER

WASHER

NUT

HARNESS

COMPRESSOR

W Call for Heating

B Reversing valve Energized in heating mode

GL Call for Low Fan

GH Call for High Fan

R 24VAC Power From Unit

Y Call for Cooling

05

PART NO. REV

LEGEND

92160001

LEGEND FOR TSTAT WIRING HARNESS

C COMMON

FUSE HOLDER

FUSE

BLACK

INDOOR COIL SENSOR

OUTDOOR COIL SENSOR

SERVICE DISPLAY

AMBIENT

AIR SENSOR

L2 or ACN

L1

VOLTAGE SELECTION SWITCH

SET VOLTAGE TO 230V

RV

RELAY

FAN 4

RELAY

FAN 3

RELAY

FAN 2

RELAY

FAN 1

RELAY

HEAT

RELAY

HEAT

RELAY

COMP

RELAY

VOLTAGE SWITCH

WIRING DIAGRAM

COOL, ELECTRIC HEAT

SMALL CHASSIS, 230/208V

HEATERS: 2.5KW, 3.4KW, 5.0KW

25

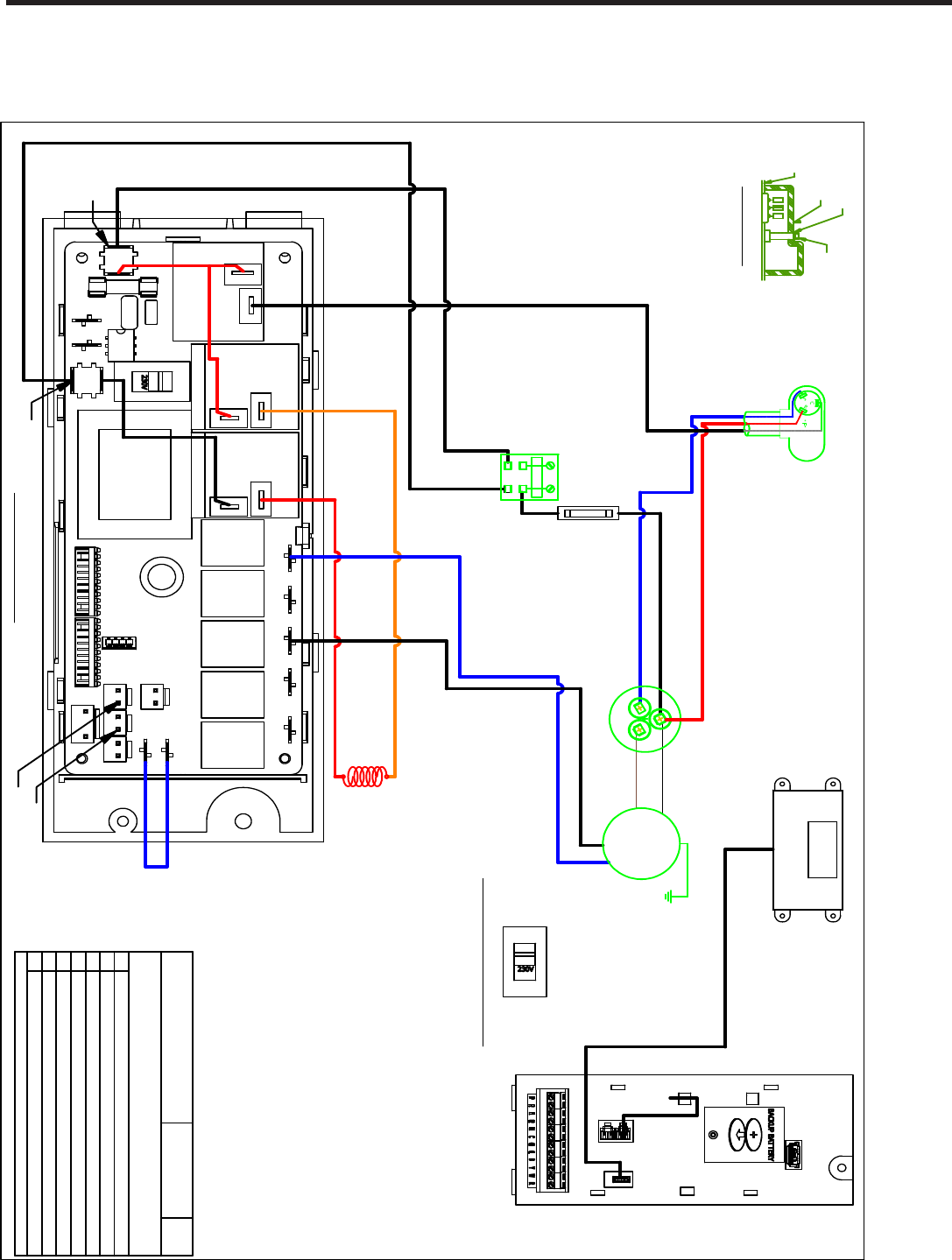

VHA 230/208 Electrical Wiring Diagram

B

L

U

E

RED

WHITE

WHITE

BLACK

GREEN

BROWN

ORANGE

C

F

A

N

L1

L2

ELECTRONIC CONTROL

"

F

"

R

S

C

TERMINAL DETAIL

BLACK

B

LA

C

K

BLUE

HEATER

2.5 KW & 3.4 KW

5.0 KW

BLACK (TO L1)

B

L

A

C

K

RED

QUICK

DISCONNECT

COIL

SOLENOID

CAPACITOR

BLOWER

MOTOR

TO MOTOR

MOUNT

W

H

IT

E

5

2

0

(

T

O

L

2

)

COMPRESSOR

GASKET

TEMINAL COVER

WASHER

NUT

HARNESS

COMPRESSOR

W Call for Heating

B Reversing valve Energized in heating mode

GL Call for Low Fan

GH Call for High Fan

R 24VAC Power From Unit

Y Call for Cooling

05

PART NO. REV

LEGEND

LEGEND FOR TSTAT WIRING HARNESS

92160301

C COMMON

BLACK

H

E

R

M

FUSE

FUSE HOLDER

INDOOR COIL SENSOR

OUTDOOR COIL SENSOR

SERVICE DISPLAY

AMBIENT

AIR SENSOR

L2 or ACN

L1

VOLTAGE SELECTION SWITCH

SET VOLTAGE TO 230V

RV

RELAY

FAN 4

RELAY

FAN 3

RELAY

FAN 2

RELAY

FAN 1

RELAY

HEAT

RELAY

HEAT

RELAY

COMP

RELAY

VOLTAGE SWITCH

WIRING DIAGRAM

COOL, ELECTRIC HEAT, HEAT PUMP

SMALL CHASSIS, 230/208V

HEATERS: 2.5KW, 3.4KW, 5.0KW

(IF APPLICABLE)

26

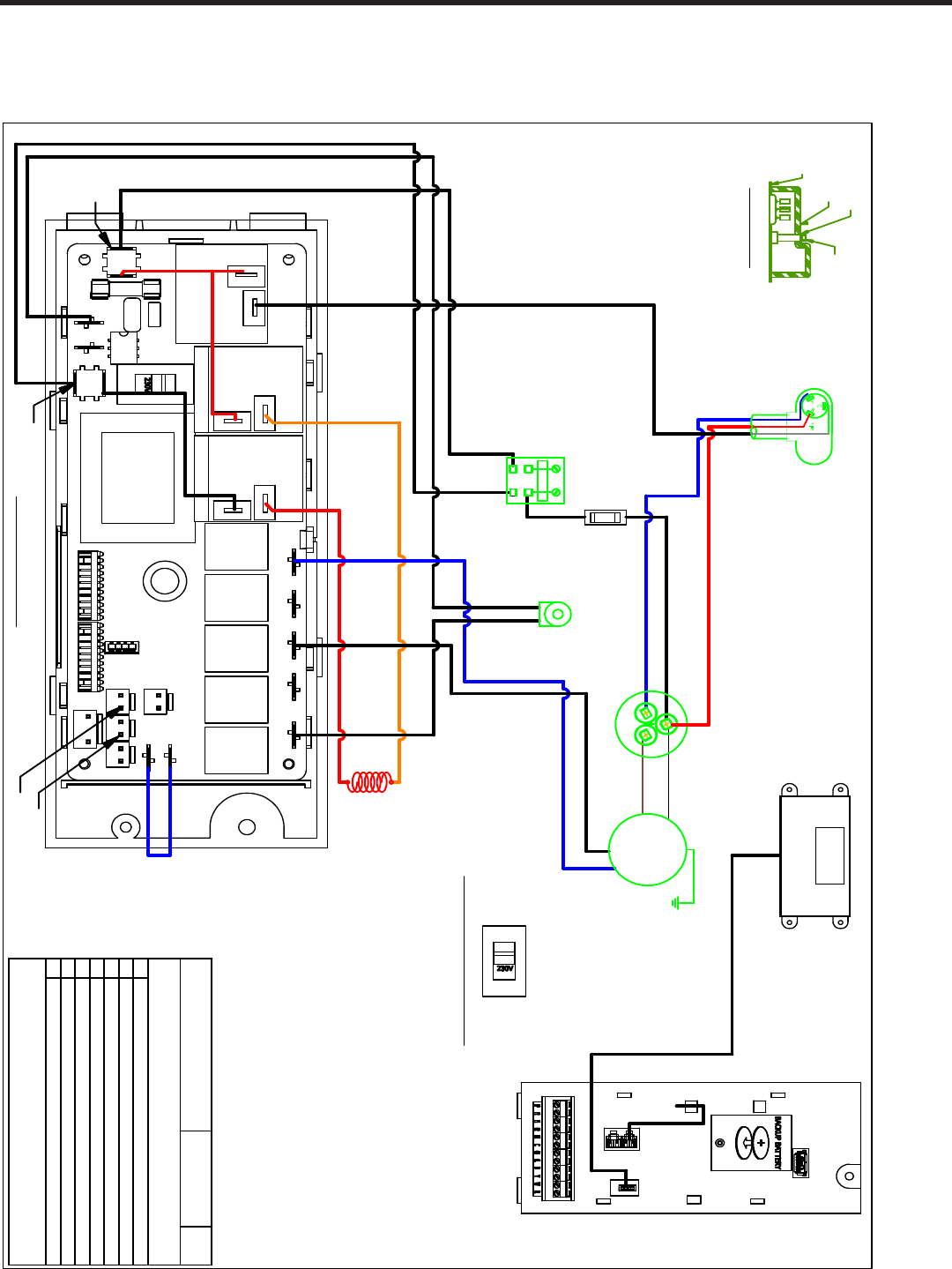

VHA 265 Electrical Wiring Diagram

B

L

U

E

RED

WHITE

BLACK

GREEN

BROWN

BLACK

C

F

A

N

L1

L2

ELECTRONIC CONTROL

"

F

"

R

S

C

TERMINAL DETAIL

BLACK

W

H

I

T

E

BLUE

HEATER

2.5 KW & 3.4 KW

5.0 KW

B

L

A

C

K

WHITE

QUICK

DISCONNECT

COIL

SOLENOID

CAPACITOR

MOTOR

TO MOTOR

MOUNT

B

L

A

C

K

COMPRESSOR

GASKET

TEMINAL COVER

WASHER

NUT

HARNESS

COMPRESSOR

W Call for Heating

B Reversing valve Energized in heating mode

GL Call for Low Fan

GH Call for High Fan

R 24VAC Power From Unit

Y Call for Cooling

03

PART NO. REV

LEGEND

LEGEND FOR TSTAT WIRING HARNESS

92160303

C COMMON

BLACK

H

E

R

M

F

U

S

E

F

U

S

E

H

O

L

D

E

R

ORANGE

RED

RELAY

BLACK

RED

B

L

A

C

K

B

L

A

C

K

R

E

D

B

R

O

W

N

WHITE

BLACK

GROUND TO CHASIS

BUILDING

GROUND

265V 60Hz

2Ø 2 WIRES

FLA

MCA

MOP

FUSE

BLOCK

TRANSFORMER

W

H

I

T

E

INDOOR

COIL

SENSOR

OUTDOOR COIL SENSOR

SERVICE DISPLAY

AMBIENT

AIR SENSOR

L2 or ACN

L1

VOLTAGE SELECTION SWITCH

SET VOLTAGE TO 230V

RV

RELAY

FAN 4

RELAY

FAN 3

RELAY

FAN 2

RELAY

FAN 1

RELAY

HEAT

RELAY

HEAT

RELAY

COMP

RELAY

VOLTAGE SWITCH

WIRING DIAGRAM

COOL, ELECTRIC HEAT, HEAT PUMP

SMALL CHASSIS, 265V

HEATERS: 2.5KW, 3.4KW, 5.0KW

F

U S

E

A

F

U S E

A

F

U S E

A

JUMPER

WIRE

TRANSFORMER

ELECTRONIC CONTROL

(REAR VIEW)

27

Final Installation Checklist

Final Installation Checklist

Inspect and ensure that all components and

accessories have been installed properly and

that they have not been damaged during the

installation process.

Ensure that all installation instructions

concerning clearances around the unit have

been adhered to.

Check to ensure that the unit air filter, indoor

coil, and outdoor coil are free from any

obstructions.

Ensure that the circuit breaker(s) or fuse(s)

and supply circuit wire size have been sized

correctly.

Check the condensate water drain(s) to

ensure that they are adequate for the

removal of condensate water and that they

meet approval of the end user.

Ensure that the entire installation is in

compliance with all applicable national and

local codes and ordinances having

jurisdiction.

Secure all access panels (i.e. front cover

and/or control box), apply power to the unit

The unit commissioning should be done at

this time to ensure unit function.

NOTE: Maintaining a log for recording the dates

of maintenance and/or service is recommended,

and should be suggested to the owner or

operator of the equipment.

Present the owner or operator of the

equipment with the Installation & Operation

Manual, all accessory installation

instructions, and the name, address and

telephone number of the Authorized Friedrich

Warranty Service Company in the area for

future reference if necessary.

Chassis Operation

Cooling Operation

The set point must be at least 3°F below room

temperature to ensure compressor operation.

In the cooling mode, when demand is present, the

indoor blower and outdoor fan will operate. The

compressor will vary operating speed to maintain

desired set point.

Heat Pump Operation

The set point must be greater than 3°F but not

greater than 6°F above room temperature to ensure

compressor operation.

In the heating mode, when demand is present, the

indoor blower and outdoor fan will operate. The

compressor will vary operating speed to maintain

desired set point.

Electric Heat Operation

If the set-point is greater than 6°F above room

temperature, the heat pump operation will be

terminated and the electric heater will be energized

to satisfy the heating demand.

If heat pump operation is not available due to

defrost or error, the electric heater will be used to

satisfy heating demand.

FreshAire™

The FreshAire™ System (optional) delivers outside

air to the indoor space. The module has a fan that

draws outdoor air into the module. The outdoor air

leaves the module through a filter and enters the

indoor space in front of the indoor conditioning coil.

The outdoor air mixes with the return air and is

drawn through the indoor conditioning coil. The

optional module can be configured as either a single

(F option) or a dual (D option)..

Inspect and ensure that all components and

accessories have been installed properly and

that they have not been damaged during the

installation process.

Ensure that all installation instructions

concerning clearances around the unit have been

adhered to.

Check to ensure that the unit air lter, indoor

coil, and outdoor coil are free from any

obstructions.

Ensure that the circuit breaker(s) or fuse(s) and

supply circuit wire size have been sized correctly.

Check the condensate water drain(s) to ensure

that they are adequate for the removal of

condensate water and that they meet approval of

the end user.

Ensure that the entire installation is in

compliance with all applicable national and local

codes and ordinances having jurisdiction.

ENSURE THAT THE SUPPLY VOLTAGE TO THE

UNIT IS WITHIN THE OPERATING RANGE

Secure all access panels (i.e. front cover and/or

control box), apply power to the unit.

The unit commissioning should be done at this

time to ensure unit function.

NOTE: Maintaining a log for recording the dates

of maintenance and/or service is recommended,

and should be suggested to the owner or

operator of the equipment.

Present the owner or operator of the equipment

with the Installation & Operation Manual, all

accessory installation instructions, and the name,

address and telephone number of the Authorized

Friedrich Warranty Service Company in the area

for future reference if necessary.

NOTE: The unit is not designed to guarantee

continuous operation with outdoor ambient

conditions greater than 110F.

•

•

•

•

•

•

•

•

•

Chassis Operation

Fresh Air Door

The fresh air door is an “intake” system. It is

opened via a slide mechanism on the front of the

chassis located just above the indoor coil. Move

the slide left to open and right to close the door.

The system is capable of delivering up to 60 CFM of

outdoor air.

Low Ambient Compressor Cut Out

Each chassis is equipped with low ambient

protection that is determined by thermistor

feedback. The feedback will prevent the

compressor from operating at low suction

temperatures.

Room Freeze Protection

This feature will monitor the indoor room

conditions and in the event that the room falls

below 40F, the unit will cycle on high fan with the

electric heater. This occurs regardless of mode.

28

Inspect and Clean Indoor Air Coil

Eventually, minor amounts of lint and dirt may pass

through the lter and collect on the indoor-air coil. These

minor accumulations can be carefully vacuumed away

with a brush attachment on a vacuum cleaner. Care must

be taken to avoid bending the aluminum ns on the coil.

Bent ns should be straightened using a special n tool

available from most HVAC supply depots.

Inspect Outdoor Air (OA) Intake and Exhaust

The unit’s outdoor-air intake and outdoor-air exhaust paths

must remain clear. Keep it free of all debris, snow, or ice.

The OA intake should also be kept free of obstructions.

Blocking the OA exhaust or OA intake opening will reduce

the efciency of your unit and could damage it.

Inspect and Clean Condensate Drain

The condensate drain must be routed to a suitable drainage

area. Check the unit condensate drain periodically. Keep

it free of anything that may block or impede the ow of

condensate water. If there is any accumulation of foreign

matter in the drain pipe, it should be removed and cleaned.

The entire drain line must be protected from freezing.

Warranty

All warranty service work must be done by an authorized

servicer. See Product Warranty, and consult your dealer or

contractor for details.

Electronic Control Error Code

Diagnostics and Test Mode

Error Code Diagnostics

The electronic control continuously monitors the Vert-I-

Pak unit operation and will store error codes if certain

conditions are observed. In some cases the unit may take

action and shut the unit off until conditions are corrected.

To access the error code menu press the ‘ENTER’ button. If

error codes are present they will be displayed. If multiple

codes exist you can toggle between error codes using the

‘SCROLL’ button.

Service & Warranty

To Remove the Chassis from the Closet:

1. Switch the unit off at the thermostat.

2. Disconnect the power coming into the unit from

the main breaker panel or the closet mounted

disconnect.

3. Disconnect the electrical connection.

4. Disconnect the duct work.

5. Slide the chassis out of the wall plenum.

6. Slide and slightly lift the chassis out of the utility

closet.

Servicing / Chassis Quick Change Outs

The chassis is designed for quick disconnect

and change out. For minor electrical service, the

control box cover lifts straight up after the screws

and disconnect pull-out are removed. For major

electrical,refrigeration, and fan service the chassis

should be removed from the utility closet.

Routine Maintenance Performing Routine

Maintenance

With proper maintenance and care, your system will

operate economically and dependably. Maintenance

can be accomplished easily by referring to the

following directions. However, before performing any

maintenance, see above stated WARNING.

Replace Air Filter

A dirty air lter reduces the efciency of your Vert-

I-Pak unit and allows lint and dirt to accumulate on

the indoor coil. Lint and dirt on the indoor coil can

damage your unit. The air lter should be replaced

as it becomes dirty. To replace the chassis mounted

return air lter:

1. Slide the holders away from the lter.

2. Remove the lter.

3. Install a new disposable lter.

4. The unit lter size is 20″ x 14″ x 1″

NOTE: DO NOT OPERATE YOUR SYSTEM

WITHOUT A FILTER IN PLACE OR BLOCK THE FRONT

OF THE UNIT RETURN AIR OPENING.

Electrical Shock Hazard

Pull out electrical disconnect on front of

the chassis and turn o all power to unit

before servicing.

Failure to do so can result in property

damage, personal injury and/or death.

Cut/Sever Hazard

Some edges may be sharp, use gloves

or other hand protection when handling

unit.

Failure to do so can result in minor to

moderate personal injury.

29

Unit Control Panel

The display has four (4) digits. The left two digits indicate the error code (1-24) and the “On/Off” icons above these digits

indicate the current state of the error code. The right two digits show the history count (up to 99) of the associated error.

The display contains a maintenance icon (wrench) that will illuminate when the unit requires maintenance.

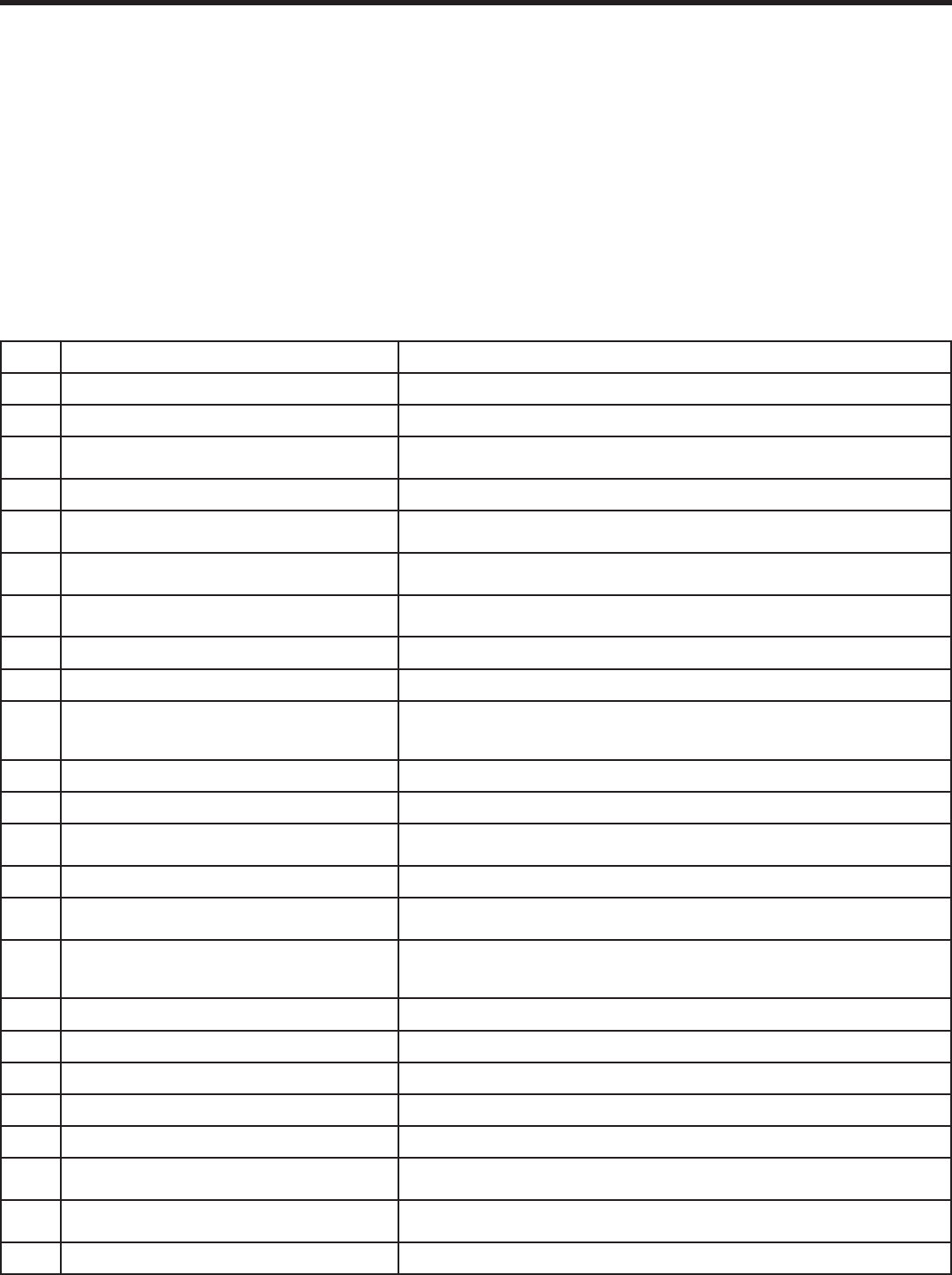

Diagnostic Error Codes

Code Description Action

1 Front panel button stuck for more than 20 seconds Continue to monitor for “open” switch.

2 Input voltage out of specication Unit stops and opens all relays until voltage is back within specication.

3 Indoor temperature sensor open or shorted The unit defaults the sensor to 75F in COOLING and 68F in HEATING and continues

operation.

4 Indoor coil temperature sensor is open or shorted The unit defaults the sensor to 40F and continues operation.

5 Outdoor coil temperature sensor is open or shorted The unit defaults the sensor to 20F and continues operation. The unit will default to

electric heat in HEATING if available.

6 Outdoor coil > (greater than) 175F The unit will shut down for 5 minutes then resume operation. If the failure occurs

three times the severity is increased and unit operation is locked out.

7 Indoor coil < (less than) 30F for 2 consecutive

minutes

The compressor will turn off and the high fan speed will run. When the coil tempera-

ture rises above 45F the unit will resume normal operation.

8 Unit cycles > (greater than) 9 times per hour The unit will continue to operate and be monitored.

9 Unit cycles < (less than) 3 times per hour The unit will continue to operate and be monitored.

10 Room freeze protection Only applicable when electric heat is available. Will run high speed fan and electric

heat until the room temperature reaches 46F. The unit will display “FRZ” during

operation. Logged only.

11 Thermostat or connection issue The unit will not operate

12 Not Applicable Not Applicable

13 High pressure limit switch is open

***Applies to 24000 BTU/hr units only

Compressor is turned off and high speed fan is run until the switch closes. 3 occur-

rences within an hour will lock out unit operation.

14 Not Applicable Not Applicable

15 Heat pump error If the indoor coil temperature is less than the ambient temperature for 3 minutes the

unit will use electric heat to satisfy heating demand.

16 Temperature beyond operating limits Occurs if the ambient temperature falls below 0F or above 130F. The unit is turned off

until the temperature returns within operating range then continues normal opera-

tion.

17 Minimum conguration not met The compressor must be enabled and have at least 2 fan speeds

18 Not Applicable Not Applicable

19 Not Applicable Not Applicable

20 Not Applicable Not Applicable

21 Not Applicable Not Applicable

22 Outdoor coil temperature < 30F for 2 consecutive

minutes

Unit will use electric heat to satisfy heating demands until the coil temperature rises

above 45F. Applicable for heat pump models only.

23 Frost protection Unit will run active defrost for a minimum of 6 minutes when the heat pump run-time

is greater than 60 minutes and the outdoor coil temperature is 26F or less.

24 Not Applicable Not Applicable

30

THIS PAGE INTENTIONALLY LEFT BLANK.