--28

°

to 290

°

C

(--18

°

to 550

°

F)

Efficient, reliable medium-

temperature-range fluid

heat transfer fluid

THERMINOL

®

55

Eastman Therminol® 55 heat transfer fluid is

a unique, synthetic fluid designed to provide

reliable, consistent heat transfer performance

over a long life at maximum bulk temperatures

up to 290°C (550°F).

•

Delivers excellent cost performance over the fluid life when

compared to common mineral oil-based heat transfer fluids,

even when operating temperatures reach a maximum

extended use temperature of 315°C (600°F).

•

More readily pumpable at low temperatures than the majority

of other mineral oil-based heat transfer fluids.

•

Savings in capital, operations, and maintenance costs are

often achieved when used in applications that traditionally

use steam as a heating medium.

Therminol 55 is available in the Americas and Asia-

Pacific. Contact your local Eastman Therminol sales

representative for more information.

Physical and chemical

characteristics

Therminol 55 fluid is designed for use in nonpressurized/low-

pressure, indirect heating systems. It delivers efficient, dependable,

uniform process heat with no need for high pressures. The high

boiling point of Therminol 55 helps reduce the volatility and fluid

leakage problems associated with other fluids.

The recommended maximum bulk and film temperatures for

Therminol 55 are based on industry-standard thermal studies.

Operation at or below these temperature maximums can

provide long service life under most operating conditions.

Actual fluid life is dependent on the total system design and

operation and can vary by heat transfer fluid chemistry. As

fluid ages, the formation of low- and high-boiling compounds

may result. Low-boiling compounds should be vented from the

system as necessary to a safe location away from personnel and

sources of ignition and in compliance with applicable regulations

and laws. The high-boiling compounds can be very soluble in

the fluid. Significant overheating or fluid contamination will

accelerate decomposition and may result in increased high-

boiler and solids concentrations. Excess solids can typically be

filtered for removal.

Therminol 55 has been shown to be significantly less sensitive

than mineral oils to the negative consequences (sludging,

fouling) of thermal oxidation. Eastman recommends that

systems utilizing Therminol 55 fluid should be blanketed with an

atmosphere of inert gas to protect against the effects of fluid

oxidation on its performance and life expectancy. Pressure relief

device(s) should be installed where required.

Therminol 55 is noncorrosive to metals commonly used in the

construction of heat transfer systems.

While Therminol 55 has a relatively high flash point, it is not

classified as a fire-resistant heat transfer fluid. Consequently,

the use of protective devices may be required to minimize fire

risk and users of Therminol 55 should check with their safety

and risk management experts for specific instructions.

800

–225

Max. extended use temp, 600

Max. bulk use temp., 550

Min. use temp., –18

°F

427

–145

315

290

–28

°C

heat transfer fluid

THERMINOL

®

55

Typical properties

a

a

These data are based on samples tested in the laboratory and are not guaranteed for all samples. Contact us for complete sales specifications for

Therminol 55 fluid. Does not constitute an express warranty. See disclaimer on the back page of this bulletin.

For the technical service contact in your region,

visit the CONTACT US page on our website, www.therminol.com.

Appearance Clear, yellow liquid

Composition Synthetic hydrocarbon mixture

Maximum bulk temperature 290°C (550°F)

Maximum extended use temperature 315°C (600°F)

Maximum film temperature 335°C (635°F)

Normal boiling point 351°C (664°F)

Pumpability, at 300 mm²/s (cSt) –8°C (17°F)

Pumpability, at 2000 mm²/s (cSt) –28°C (–18°F)

Flash point, COC (ASTM D-92) 177°C (350°F)

Autoignition temperature (ASTM E-659) 366°C (691°F)

Autoignition temperature (DIN 51794) 382°C (719°F)

Pour point (ISO 3016) –54°C (–65°F)

Minimum liquid temperatures for fully developed turbulent flow (N

Re

> 10000)

10 ft/s, 1-in. tube (3.048 m/s, 2.54-cm tube) 67°C (152°F)

20 ft/s, 1-in. tube (6.096 m/s, 2.54-cm tube) 45°C (114°F)

Minimum liquid temperatures for transitional region flow (N

Re

> 2000)

10 ft/s, 1-in. tube (3.048 m/s, 2.54-cm tube) 24°C (75°F)

20 ft/s, 1-in. tube (6.096 m/s, 2.54-cm tube) 11°C (52°F)

Coefficient of thermal expansion @ 200°C 0.000961/°C (0.000534/°F)

Heat of vaporization at maximum use temperature 228 kJ/kg (98.1 Btu/lb)

Average molecular weight 320

Pseudocritical temperature 512°C (953°F)

Pseudocritical pressure 13.2 bar (191 psia)

Pseudocritical density 258 kg/m

3

(16.1 lb/ft

3

)

Moisture content, maximum (ASTM E-203) 150 ppm

Dielectric constant @ 23°C (ASTM D-924) 2.23

To create your own customized table

with preferred properties, units of measure,

and temperature intervals, visit

www.therminol.com/resources

and download the Therminol heat transfer fluid calculator.

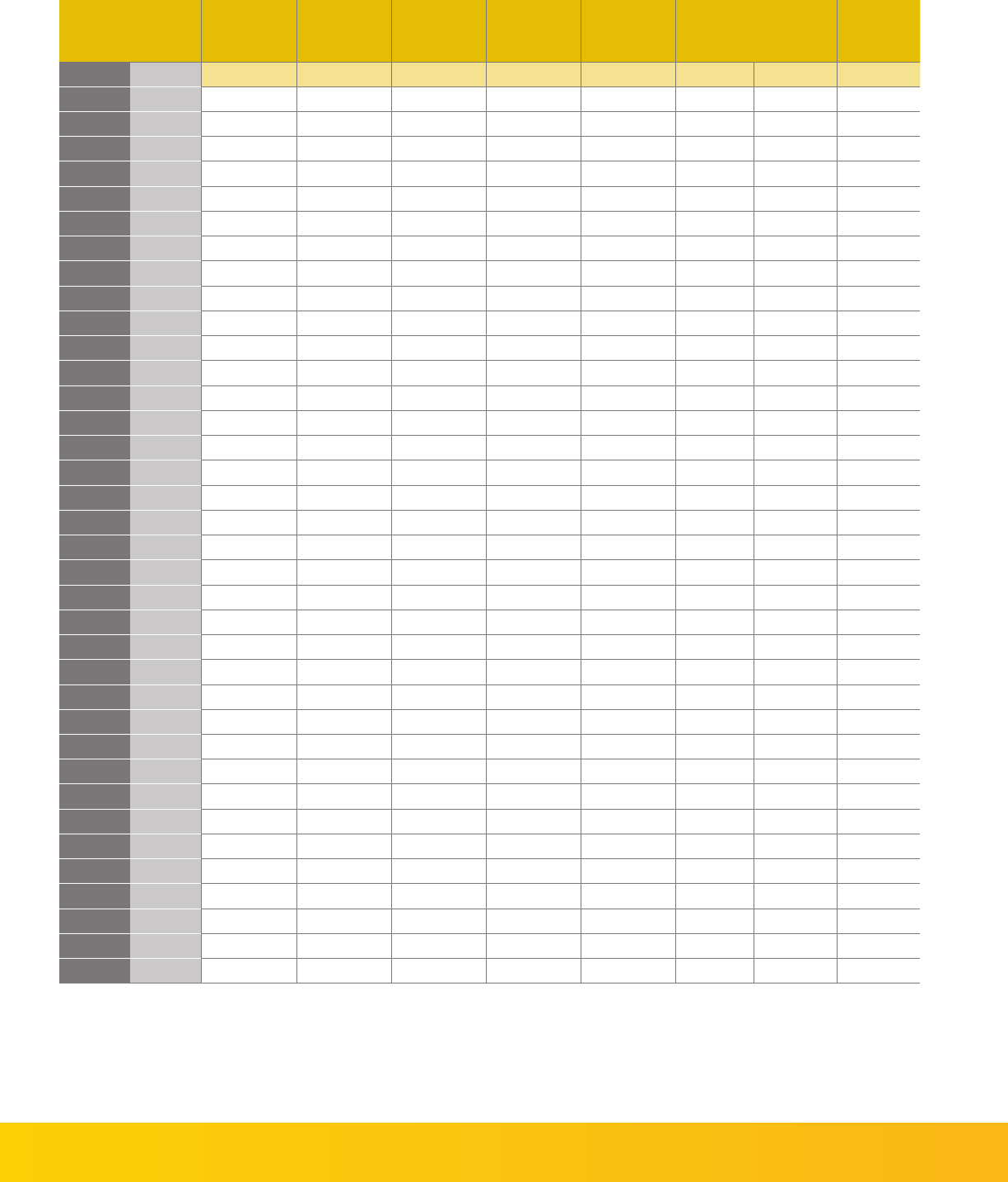

Temperature

Liquid

density

Liquid

heat

capacity

Heat of

vaporization

Liquid

enthalpy

b

Liquid

thermal

conductivity Liquid viscosity

c

Vapor

pressure

d

°C °F kg/m

3

kJ/(kg·K) kJ/kg kJ/kg W/(m·K) cP (mPa·s) cSt (mm

2

/s) kPa

–28

–18 904 1.73 418.0 –18.8 0.1340 1820 2010 —

–20

–4 899 1.76 412.0 –3.9 0.1331 756 841 —

–10

14 892 1.80 405.0 13.9 0.1319 309 346 —

0

32 885 1.83 398.1 32.0 0.1307 143 162 —

10

50 878 1.87 391.3 50.6 0.1296 73.8 84.0 —

20

68 872 1.91 384.6 69.4 0.1284 41.6 47.7 —

30

86 865 1.94 377.9 88.7 0.1273 25.2 29.2 —

40

104 858 1.98 371.4 108.3 0.1261 16.3 19.0 —

50

122 852 2.01 364.9 128.2 0.1249 11.1 13.1 —

60

140 845 2.05 358.5 148.5 0.1238 7.93 9.39 —

70

158 838 2.08 352.2 169.2 0.1226 5.89 7.02 —

80

176 831 2.12 345.9 190.2 0.1214 4.52 5.43 0.011

90

194 825 2.16 339.8 211.6 0.1203 3.56 4.32 0.019

100

212 818 2.19 333.7 233.3 0.1191 2.88 3.52 0.032

110

230 811 2.23 327.8 255.4 0.1179 2.38 2.93 0.054

120

248 804 2.26 321.8 277.9 0.1168 2.00 2.49 0.088

130

266 797 2.30 316.0 300.7 0.1156 1.71 2.14 0.140

140

284 790 2.33 310.2 323.8 0.1144 1.48 1.87 0.219

150

302 784 2.37 304.5 347.3 0.1133 1.29 1.65 0.334

160

320 777 2.40 298.8 371.2 0.1121 1.14 1.47 0.501

170

338 770 2.44 293.2 395.4 0.1109 1.02 1.32 0.738

180

356 763 2.47 287.7 420.0 0.1098 0.913 1.20 1.07

190

374 755 2.51 282.2 444.9 0.1086 0.825 1.09 1.53

200

392 748 2.54 276.7 470.1 0.1074 0.749 1.00 2.15

210

410 741 2.58 271.3 495.7 0.1062 0.683 0.921 2.98

220

428 734 2.61 265.9 521.7 0.1051 0.625 0.852 4.07

230

446 726 2.65 260.5 548.0 0.1039 0.574 0.790 5.51

240

464 719 2.68 255.1 574.7 0.1027 0.528 0.735 7.37

250

482 711 2.72 249.7 601.7 0.1015 0.488 0.686 9.76

260

500 704 2.75 244.3 629.1 0.1004 0.451 0.641 12.8

270

518 696 2.79 239.0 656.8 0.0992 0.418 0.600 16.6

280

536 688 2.83 233.5 684.9 0.0980 0.387 0.563 21.3

290

554 680 2.86 228.1 713.3 0.0968 0.360 0.529 27.2

300

572 672 2.90 222.6 742.1 0.0957 0.334 0.497 34.4

310

590 663 2.93 217.1 771.2 0.0945 0.311 0.468 43.1

320

608 655 2.97 211.5 800.7 0.0933 0.289 0.441 53.7

Liquid properties of Therminol

®

55 heat transfer fluid by temperature

a

(SI units)

a

Maximum recommended bulk temperature 290°C (550°F). These data are based on samples tested in the laboratory and are not guaranteed for all samples. Contact us for complete

sales specifications for Therminol 55 fluid.

b

Liquid enthalpy basis is –17.8ºC (0ºF).

c

1 cSt = 1 mm

2

/s and 1 mPa•s =1 cP.

d

100 kPa =1 bar.

e

Maximum extended use temperature

is 315ºC (600ºF).

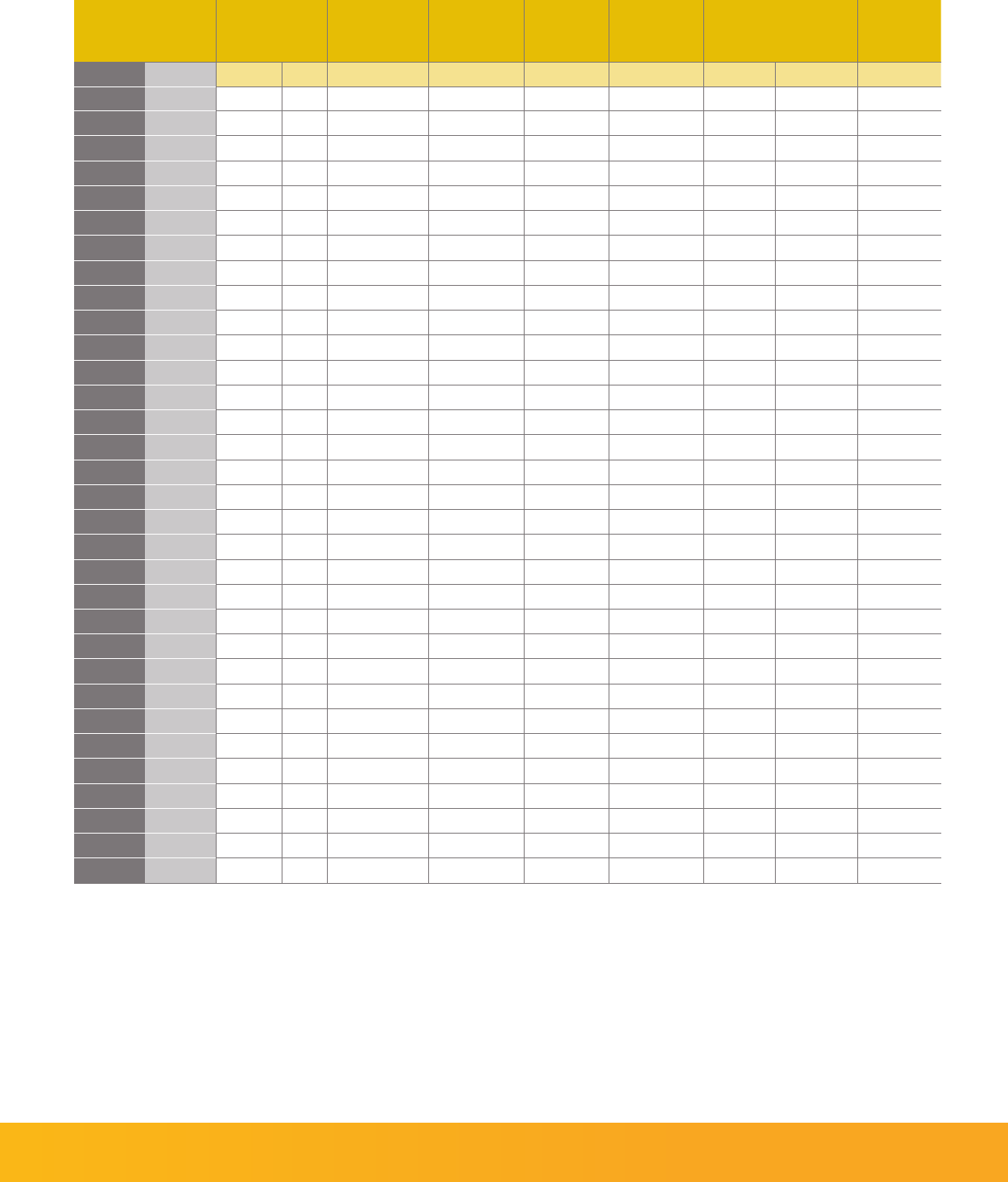

Liquid properties of Therminol

®

55 heat transfer fluid by temperature

a

(English units)

Temperature Liquid density

Liquid

heat capacity

Heat of

vaporization

Liquid

enthalpy

b

Liquid

thermal

conductivity Liquid viscosity

c

Vapor

pressure

d

°F °C lb/gal lb/ft

3

Btu/(lb·°F) Btu/lb Btu/lb Btu/(ft·h·°F) lb/(ft·h) cSt (mm

2

/s) psia

–18

–28 7.55 56.5 0.414 179.8 –8.1 0.0775 4400 2010 —

0

–18 7.49 56.0 0.423 176.6 0.0 0.0768 1480 683 —

20

–7 7.42 55.5 0.433 173.3 8.6 0.0760 571 265 —

40

4 7.36 55.1 0.442 170.0 17.3 0.0753 255 120 —

60

16 7.30 54.6 0.452 166.7 26.2 0.0745 128 60.7 —

80

27 7.24 54.1 0.461 163.5 35.4 0.0738 71.5 34.1 —

100

38 7.18 53.7 0.471 160.4 44.7 0.0731 43.2 20.8 —

120

49 7.11 53.2 0.480 157.3 54.2 0.0723 28.0 13.6 —

140

60 7.05 52.7 0.490 154.2 63.9 0.0716 19.2 9.39 —

160

71 6.99 52.3 0.499 151.2 73.8 0.0708 13.8 6.82 —

180

82 6.93 51.8 0.509 148.2 83.9 0.0701 10.3 5.15 0.0018

200

93 6.86 51.3 0.518 145.3 94.1 0.0693 8.01 4.03 0.0033

220

104 6.80 50.9 0.527 142.4 104.6 0.0686 6.39 3.24 0.0059

240

116 6.74 50.4 0.537 139.6 115.2 0.0678 5.22 2.67 0.010

260

127 6.67 49.9 0.546 136.8 126.1 0.0671 4.35 2.25 0.017

280

138 6.61 49.4 0.556 134.0 137.1 0.0663 3.69 1.92 0.029

300

149 6.55 49.0 0.565 131.3 148.3 0.0656 3.17 1.67 0.046

320

160 6.48 48.5 0.574 128.6 159.7 0.0648 2.76 1.47 0.073

340

171 6.42 48.0 0.584 125.9 171.3 0.0641 2.43 1.31 0.112

360

182 6.35 47.5 0.593 123.2 183.0 0.0633 2.16 1.17 0.168

380

193 6.28 47.0 0.602 120.6 195.0 0.0626 1.93 1.06 0.248

400

204 6.22 46.5 0.612 118.0 207.1 0.0618 1.74 0.964 0.360

420

216 6.15 46.0 0.621 115.4 219.5 0.0610 1.57 0.881 0.515

440

227 6.08 45.5 0.630 112.8 232.0 0.0603 1.43 0.810 0.724

460

238 6.01 45.0 0.640 110.3 244.7 0.0595 1.30 0.747 1.00

480

249 5.94 44.5 0.649 107.7 257.6 0.0588 1.19 0.691 1.37

500

260 5.87 43.9 0.658 105.1 270.6 0.0580 1.09 0.641 1.85

520

271 5.80 43.4 0.668 102.5 283.9 0.0573 1.00 0.596 2.47

540

282 5.73 42.8 0.677 100.0 297.3 0.0565 0.922 0.555 3.27

560

293 5.65 42.3 0.686 97.3 311.0 0.0558 0.849 0.518 4.27

580

304 5.58 41.7 0.696 94.7 324.8 0.0550 0.783 0.484 5.52

600

e

316 5.50 41.1 0.705 92.1 338.8 0.0542 0.722 0.453 7.07

In-service heat transfer fluid

sample analysis

When Therminol heat transfer fluids are used within suggested

temperature limits, they may provide years of trouble-free service.

To help users get maximum life, Eastman offers testing of

in-service heat transfer fluids to detect contamination, moisture,

thermal degradation, and other conditions that may impact

system performance. This comprehensive analysis includes

acid number, kinematic viscosity, insoluble solids, low boilers,

high boilers, and moisture content. Additional special analyses

are available on request. Sample analysis includes sample

collection kits that are easy to use. Most systems should be

sampled annually. Users should also sample anytime a fluid-

related problem is suspected.

Results of the test are presented in a detailed report that provides

suggestions for corrective action. Test results are stored in a

database for future reference. Customers can access their specific

test information via my.therminol.com.

Technical service hotline

Experienced technical service specialists can help answer your

questions regarding heat transfer fluid selection, system start-ups,

system design, and operational issues.

System design support

Eastman regularly assists some of the world’s largest engineering,

chemical, and equipment manufacturing companies on the design

and operation of heat transfer systems. Our liquid phase and

vapor phase design guide information and system design data

have been field tested in numerous installations. Eastman also

conducts engineering seminars for customers, engineering firms,

and equipment manufacturers to cover a wide range of heat

transfer fluid system design and operation issues. Customers can

request a technical service visit to audit heat transfer systems for

fluid loss and leak prevention opportunities.

Operational training

Eastman believes that by sharing our experience with customers,

we can help improve system design, promote safety, and reduce

overall cost. Customers can take advantage of Eastman’s heat

transfer system operation and product training programs. These

programs are customized to suit the varied needs of frontline

technicians, operations supervisors, and maintenance technicians

to design engineers. Customers can also receive training assistance

for dealing with important topics like fluid safety and handling.

Safety awareness training

At Eastman, we’re “All in for Safety.” We provide our customers

safety awareness training that focuses on the design, start-up,

operation, and maintenance of heat transfer fluid systems.

Start-up assistance

Eastman provides start-up assistance by reviewing procedures

and offering suggestions to reduce typical problems. Customers

can also receive help by calling their local Eastman technical

specialist or through on-site assistance.

Flush fluid and fluid refill

Liquid phase heat transfer systems can be cleaned with Therminol®

FF flushing fluid. After the system is flushed, the appropriate liquid

phase Therminol heat transfer fluid can be added.

Fluid trade-in program*

As part of our commitment to sustainability

and the environment, Eastman offers a trade-in

program for used Therminol and competitive heat

transfer fluids. Depending on the fluid and its

condition, it may be turned in for potential credit

towards the purchase of new Therminol heat

transfer fluid.

TLC Total Lifecycle Care

®

*Available in North America. Contact your local sales representative for more information.

Eastman’s TLC Total Lifecycle Care

®

program is

designed to support Therminol customers throughout

their systems’ life cycle. This comprehensive program

includes system design support, start-up assistance,

training, sample analysis, flush and refill fluids, and our

fluid trade-in program. In North America, call our

hotline at 1-800-433-6997 or contact your local sales

or technical representative.

TF-25 12/15

Although the information and recommendations set forth herein are presented in good faith, Eastman Chemical

Company and its subsidiaries make no representations or warranties as to the completeness or accuracy thereof.

You must make your own determination of its suitability and completeness for your own use, for the protection

of the environment, and for the health and safety of your employees and purchasers of your products. Nothing

contained herein is to be construed as a recommendation to use any product, process, equipment, or formulation

in conflict with any patent, and we make no representations or warranties, express or implied, that the use thereof

will not infringe any patent. NO REPRESENTATIONS OR WARRANTIES, EITHER EXPRESS OR IMPLIED, OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, OR OF ANY OTHER NATURE ARE MADE HEREUNDER

WITH RESPECT TO INFORMATION OR THE PRODUCT TO WHICH INFORMATION REFERS AND NOTHING HEREIN

WAIVES ANY OF THE SELLER’S CONDITIONS OF SALE.

Safety Data Sheets providing safety precautions that should be observed when handling and storing our products

are available online or by request. You should obtain and review available material safety information before

handling our products. If any materials mentioned are not our products, appropriate industrial hygiene and other

safety precautions recommended by their manufacturers should be observed.

© 2015 Eastman Chemical Company. Eastman brands referenced herein are trademarks of Eastman Chemical

Company or one of its subsidiaries. The ® used on Eastman brands denotes registered trademark status in the U.S.;

marks may also be registered internationally. Non-Eastman brands referenced herein are trademarks of their

respective owners.

Eastman Chemical Company

Corporate Headquarters

P.O. Box 431

Kingsport, TN 37662-5280 U.S.A.

U.S.A. and Canada, 800-EASTMAN (800-327-8626)

Other Locations, +(1) 423-229-2000

www.eastman.com/locations

North America

Solutia Inc.

A subsidiary of Eastman Chemical Company

575 Maryville Centre Drive

St. Louis, MO 63141 U.S.A.

Telephone:

Customer Service, 800-426-2463

Technical Service, 800-433-6997

Fax: Customer Service, (1) 314-674-7433

Latin America

Solutia Brasil Ltda.

A subsidiary of Eastman Chemical Company

Rua Alexandre Dumas, 1711—Birmann 12—

7º Andar 04717-004

São Paulo, SP, Brazil

Telephone:

Brazil, 0800 55 9989

Other Locations, +55 11 3579 1800

Fax: +55 11 3579 1833

Europe/Middle East/Africa

Solutia Europe SPRL/BVBA

A subsidiary of Eastman Chemical Company

Corporate Village—Aramis Building

Leonardo Da Vincilaan 1

1935 Zaventem, Belgium

Telephone: +32 2 746 5000

Fax: +32 2 746 5700

Asia Pacific

Eastman (Shanghai) Chemical

Commercial Company Ltd.

Building 3, Yaxin Science & Technology Park

Lane 399 Shengxia Road

Pudong New District

201210, Shanghai, P.R. China

Telephone: +86 21 6120 8700

Fax: +86 21 5027 9229

For more information or to find the sales or technical contact nearest you, visit the “Contact us” page on our website:

www.therminol.com.