Shell Heat Transfer Oil S2 X

MSDS# 17032

Version 1.1

Material Safety Data Sheet

Effective Date 02/05/2014

According to OSHA Hazard Communication Standard, 29 CFR

1910.1200

1/9

Print Date 02/07/2014 000000020351

MSDS_US

1. MATERIAL AND COMPANY IDENTIFICATION

Material Name

:

Shell Heat Transfer Oil S2 X

Product Code

: 001D8401

Uses

: Heat transfer oil.

Manufacturer/Supplier

:

SOPUS Products

PO BOX 4427

Houston, TX 77210-4427

USA

SDS Request

: 877-276-7285

Emergency Telephone Number

Spill Information

: 877-242-7400

Health Information

: 877-504-9351

2. COMPOSITION/INFORMATION ON INGREDIENTS

Highly refined mineral oils and additives.

The highly refined mineral oil contains <3% (w/w) DMSO-extract, according to IP346.

3. HAZARDS IDENTIFICATION

Emergency Overview

Appearance and Odour

: Amber. Liquid at room temperature. Slight hydrocarbon.

Health Hazards

: Not classified as dangerous for supply or conveyance.

Safety Hazards

: Not classified as flammable but will burn.

Environmental Hazards

: Not classified as dangerous for the environment.

Health Hazards

: Not expected to be a health hazard when used under normal

conditions.

Health Hazards

Inhalation

: Under normal conditions of use, this is not expected to be a

primary route of exposure.

Skin Contact

: Prolonged or repeated skin contact without proper cleaning can

clog the pores of the skin resulting in disorders such as oil

acne/folliculitis.

Eye Contact

: May cause slight irritation to eyes.

Ingestion

: Low toxicity if swallowed.

Other Information

: Used oil may contain harmful impurities.

Signs and Symptoms

: Oil acne/folliculitis signs and symptoms may include formation

of black pustules and spots on the skin of exposed areas.

Ingestion may result in nausea, vomiting and/or diarrhoea.

Aggravated Medical

Conditions

: Pre-existing medical conditions of the following organ(s) or

organ system(s) may be aggravated by exposure to this

material: Skin.

Shell Heat Transfer Oil S2 X

MSDS# 17032

Version 1.1

Material Safety Data Sheet

Effective Date 02/05/2014

According to OSHA Hazard Communication Standard, 29 CFR

1910.1200

2/9

Print Date 02/07/2014 000000020351

MSDS_US

Environmental Hazards

: Not classified as dangerous for the environment.

Additional Information

: Under normal conditions of use or in a foreseeable emergency,

this product does not meet the definition of a hazardous

chemical when evaluated according to the OSHA Hazard

Communication Standard, 29 CFR 1910.1200.

4. FIRST-AID MEASURES

General Information

: Not expected to be a health hazard when used under normal

conditions.

Inhalation

: No treatment necessary under normal conditions of use. If

symptoms persist, obtain medical advice.

Skin Contact

: Remove contaminated clothing. Flush exposed area with water

and follow by washing with soap if available. If persistent

irritation occurs, obtain medical attention.

Eye Contact

: Flush eye with copious quantities of water. If persistent

irritation occurs, obtain medical attention.

Ingestion

: In general no treatment is necessary unless large quantities

are swallowed, however, get medical advice.

Advice to Physician

: Treat symptomatically.

5. FIRE-FIGHTING MEASURES

Clear fire area of all non-emergency personnel.

Flash point

: Typical 260 °C / 500 °F (COC)

Upper / lower

Flammability or

Explosion limits

: Typical 1 - 10 %(V)(based on mineral oil)

Auto ignition temperature

: > 320 °C / 608 °F

Specific Hazards

: Hazardous combustion products may include: A complex

mixture of airborne solid and liquid particulates and gases

(smoke). Carbon monoxide may be evolved if incomplete

combustion occurs. Unidentified organic and inorganic

compounds.

Suitable Extinguishing

Media

: Foam, water spray or fog. Dry chemical powder, carbon

dioxide, sand or earth may be used for small fires only.

Unsuitable Extinguishing

Media

: Do not use water in a jet.

Protective Equipment for

Firefighters

: Proper protective equipment including breathing apparatus

must be worn when approaching a fire in a confined space.

6. ACCIDENTAL RELEASE MEASURES

Avoid contact with spilled or released material. For guidance on selection of personal protective

equipment see Chapter 8 of this Material Safety Data Sheet. See Chapter 13 for information on

disposal. Observe the relevant local and international regulations.

Protective measures

: Avoid contact with skin and eyes. Use appropriate containment

to avoid environmental contamination. Prevent from spreading

or entering drains, ditches or rivers by using sand, earth, or

Shell Heat Transfer Oil S2 X

MSDS# 17032

Version 1.1

Material Safety Data Sheet

Effective Date 02/05/2014

According to OSHA Hazard Communication Standard, 29 CFR

1910.1200

3/9

Print Date 02/07/2014 000000020351

MSDS_US

other appropriate barriers.

Clean Up Methods

: Slippery when spilt. Avoid accidents, clean up immediately.

Prevent from spreading by making a barrier with sand, earth or

other containment material. Reclaim liquid directly or in an

absorbent. Soak up residue with an absorbent such as clay,

sand or other suitable material and dispose of properly.

Additional Advice

: Local authorities should be advised if significant spillages

cannot be contained.

7. HANDLING AND STORAGE

General Precautions

: Use local exhaust ventilation if there is risk of inhalation of

vapours, mists or aerosols. Use the information in this data

sheet as input to a risk assessment of local circumstances to

help determine appropriate controls for safe handling, storage

and disposal of this material.

Handling

: Avoid prolonged or repeated contact with skin. Avoid inhaling

vapour and/or mists. When handling product in drums, safety

footwear should be worn and proper handling equipment

should be used. Properly dispose of any contaminated rags or

cleaning materials in order to prevent fires.

Storage

: Keep container tightly closed and in a cool, well-ventilated

place. Use properly labelled and closeable containers. Store at

ambient temperature.

Product Transfer

: This material has the potential to be a static accumulator.

Proper grounding and bonding procedures should be used

during all bulk transfer operations.

Recommended Materials

: For containers or container linings, use mild steel or high

density polyethylene.

Unsuitable Materials

: PVC.

Additional Information

: Polyethylene containers should not be exposed to high

temperatures because of possible risk of distortion.

8. EXPOSURE CONTROLS/PERSONAL PROTECTION

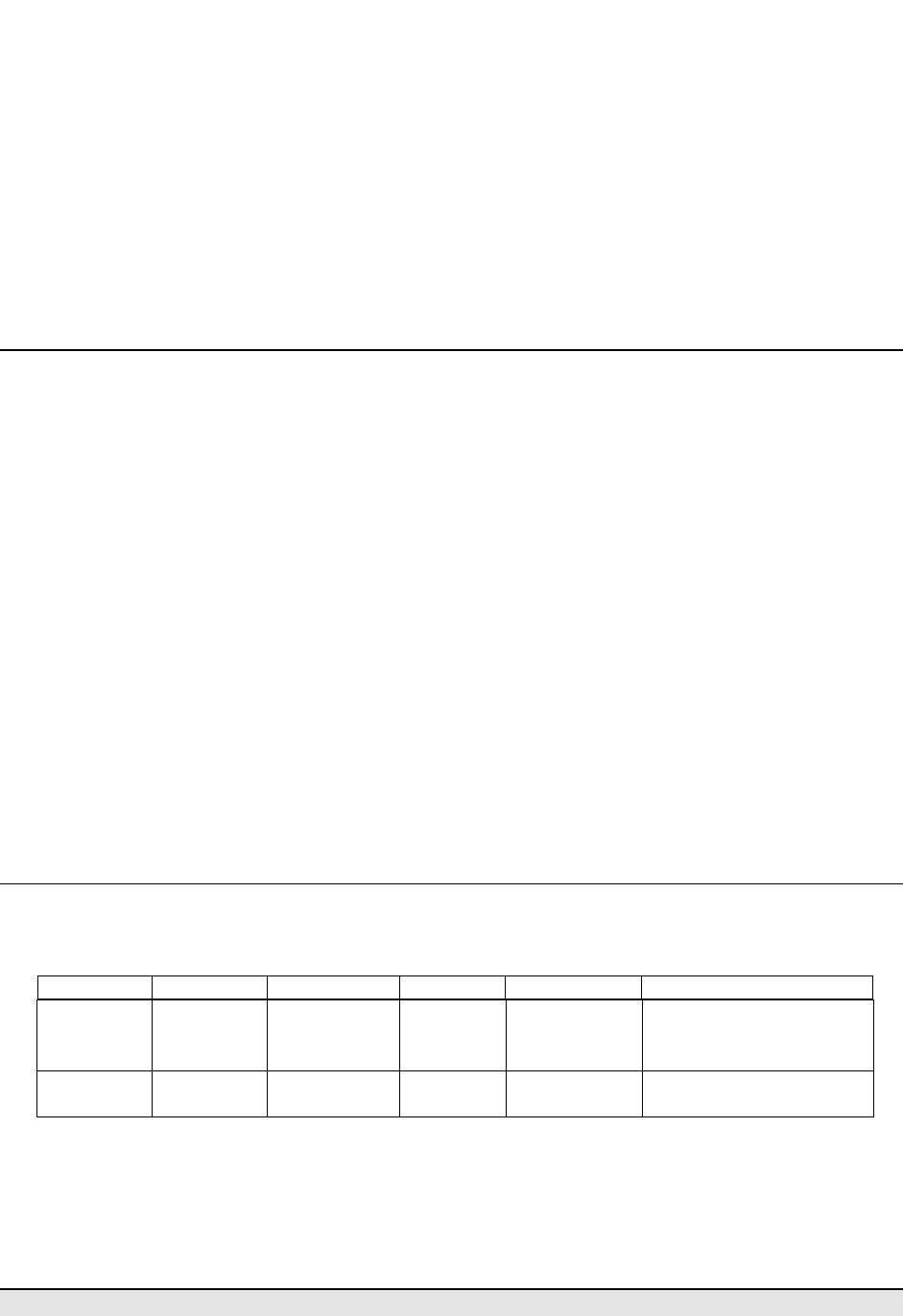

Occupational Exposure Limits

Material Source Type ppm mg/m3 Notation

Oil mist,

mineral

ACGIH TWA(Inhalabl

e fraction.)

5 mg/m3

Oil mist,

mineral

OSHA Z1 PEL(Mist.) 5 mg/m3

Biological Exposure Index (BEI)

No biological limit allocated.

Shell Heat Transfer Oil S2 X

MSDS# 17032

Version 1.1

Material Safety Data Sheet

Effective Date 02/05/2014

According to OSHA Hazard Communication Standard, 29 CFR

1910.1200

4/9

Print Date 02/07/2014 000000020351

MSDS_US

Exposure Controls

: The level of protection and types of controls necessary will vary

depending upon potential exposure conditions. Select controls

based on a risk assessment of local circumstances.

Appropriate measures include: Adequate ventilation to control

airborne concentrations. Where material is heated, sprayed or

mist formed, there is greater potential for airborne

concentrations to be generated.

Define procedures for safe handling and maintenance of

controls. Educate and train workers in the hazards and control

measures relevant to normal activities associated with this

product. Ensure appropriate selection, testing and

maintenance of equipment used to control exposure, e.g.

personal protective equipment, local exhaust ventilation. Drain

down system prior to equipment break-in or maintenance.

Retain drain downs in sealed storage pending disposal or for

subsequent recycle. Always observe good personal hygiene

measures, such as washing hands after handling the material

and before eating, drinking, and/or smoking. Routinely wash

work clothing and protective equipment to remove

contaminants. Discard contaminated clothing and footwear that

cannot be cleaned. Practice good housekeeping.

Personal Protective

Equipment

: Personal protective equipment (PPE) should meet

recommended national standards. Check with PPE suppliers.

Respiratory Protection

: No respiratory protection is ordinarily required under normal

conditions of use. In accordance with good industrial hygiene

practices, precautions should be taken to avoid breathing of

material. If engineering controls do not maintain airborne

concentrations to a level which is adequate to protect worker

health, select respiratory protection equipment suitable for the

specific conditions of use and meeting relevant legislation.

Check with respiratory protective equipment suppliers. Where

air-filtering respirators are suitable, select an appropriate

combination of mask and filter. Select a filter suitable for

combined particulate/organic gases and vapours [boiling point

>65°C(149 °F)].

Hand Protection

: Where hand contact with the product may occur the use of

gloves approved to relevant standards (e.g. Europe: EN374,

US: F739) made from the following materials may provide

suitable chemical protection: PVC, neoprene or nitrile rubber

gloves. Suitability and durability of a glove is dependent on

usage, e.g. frequency and duration of contact, chemical

resistance of glove material, dexterity. Always seek advice

from glove suppliers. Contaminated gloves should be replaced.

Personal hygiene is a key element of effective hand care.

Gloves must only be worn on clean hands. After using gloves,

hands should be washed and dried thoroughly. Application of a

non-perfumed moisturizer is recommended.

For continuous contact we recommend gloves with

breakthrough time of more than 240 minutes with preference

for > 480 minutes where suitable gloves can be identified. For

Shell Heat Transfer Oil S2 X

MSDS# 17032

Version 1.1

Material Safety Data Sheet

Effective Date 02/05/2014

According to OSHA Hazard Communication Standard, 29 CFR

1910.1200

5/9

Print Date 02/07/2014 000000020351

MSDS_US

short-term/splash protection we recommend the same, but

recognise that suitable gloves offering this level of protection

may not be available and in this case a lower breakthrough

time may be acceptable so long as appropriate maintenance

and replacement regimes are followed. Glove thickness is not

a good predictor of glove resistance to a chemical as it is

dependent on the exact composition of the glove material.

Glove thickness should be typically greater than 0.35 mm

depending on the glove make and model.

Eye Protection

: Wear safety glasses or full face shield if splashes are likely to

occur.

Protective Clothing

: Skin protection not ordinarily required beyond standard issue

work clothes.

Monitoring Methods

: Monitoring of the concentration of substances in the breathing

zone of workers or in the general workplace may be required to

confirm compliance with an OEL and adequacy of exposure

controls. For some substances biological monitoring may also

be appropriate. Validated exposure measurement methods

should be applied by a competent person and samples

analysed by an accredited laboratory. Examples of sources of

recommended exposure measurement methods are given

below or contact the supplier. Further national methods may be

available.

National Institute of Occupational Safety and Health (NIOSH),

USA: Manual of Analytical Methods http://www.cdc.gov/niosh/

Occupational Safety and Health Administration (OSHA), USA:

Sampling and Analytical Methods http://www.osha.gov/

Health and Safety Executive (HSE), UK: Methods for the

Determination of Hazardous Substances

http://www.hse.gov.uk/

Institut für Arbeitsschutz Deutschen Gesetzlichen

Unfallversicherung (IFA), Germany.

http://www.dguv.de/inhalt/index.jsp

L'Institut National de Recherche et de Securité, (INRS), France

http://www.inrs.fr/accueil

Environmental Exposure

Controls

: Take appropriate measures to fulfil the requirements of

relevant environmental protection legislation. Avoid

contamination of the environment by following advice given in

Chapter 6. If necessary, prevent undissolved material from

being discharged to waste water. Waste water should be

treated in a municipal or industrial waste water treatment plant

before discharge to surface water. Local guidelines on

emission limits for volatile substances must be observed for the

discharge of exhaust air containing vapour.

9. PHYSICAL AND CHEMICAL PROPERTIES

Appearance : Amber. Liquid at room temperature.

Odour : Slight hydrocarbon.

pH : Not applicable.

Shell Heat Transfer Oil S2 X

MSDS# 17032

Version 1.1

Material Safety Data Sheet

Effective Date 02/05/2014

According to OSHA Hazard Communication Standard, 29 CFR

1910.1200

6/9

Print Date 02/07/2014 000000020351

MSDS_US

Initial Boiling Point and

Boiling Range

: > 280 °C / 536 °F estimated value(s)

Pour point : Typical -6 °C / 21 °F

Flash point : Typical 260 °C / 500 °F (COC)

Upper / lower Flammability

or Explosion limits

: Typical 1 - 10 %(V) (based on mineral oil)

Auto-ignition temperature : > 320 °C / 608 °F

Vapour pressure : < 0.5 Pa at 20 °C / 68 °F (estimated value(s))

Specific gravity : Typical 0.865 at 15 °C / 59 °F

Density : Typical 865 kg/m3 at 15 °C / 59 °F

Water solubility : Negligible.

n-octanol/water partition

coefficient (log Pow)

: > 6 (based on information on similar products)

Kinematic viscosity : Typical 64 mm2/s at 40 °C / 104 °F

Vapour density (air=1) : > 1 (estimated value(s))

Electrical conductivity : This material is not expected to be a static accumulator.

Evaporation rate (nBuAc=1) : Data not available

10. STABILITY AND REACTIVITY

Stability

: Stable.

Conditions to Avoid

: Extremes of temperature and direct sunlight.

Materials to Avoid

: Strong oxidising agents.

Hazardous Decomposition

Products

: Hazardous decomposition products are not expected to form

during normal storage.

11. TOXICOLOGICAL INFORMATION

Basis for Assessment

: Information given is based on data on the components and the

toxicology of similar products.

Unless indicated otherwise, the data presented is

representative of the product as a whole, rather than for

individual component(s).

Acute Oral Toxicity

: Expected to be of low toxicity: LD50 > 5000 mg/kg , Rat

Acute Dermal Toxicity

: Expected to be of low toxicity: LD50 > 5000 mg/kg , Rabbit

Acute Inhalation Toxicity

: Not considered to be an inhalation hazard under normal

conditions of use.

Skin Irritation

: Expected to be slightly irritating.

Eye Irritation

: Expected to be slightly irritating.

Respiratory Irritation

: Inhalation of vapours or mists may cause irritation.

Sensitisation

: Not expected to be a skin sensitiser.

Repeated Dose Toxicity

: Not expected to be a hazard.

Mutagenicity

: Not considered a mutagenic hazard.

Carcinogenicity

: Not expected to be carcinogenic. Product contains mineral oils

of types shown to be non-carcinogenic in animal skin-painting

studies. Highly refined mineral oils are not classified as

carcinogenic by the International Agency for Research on

Cancer (IARC).

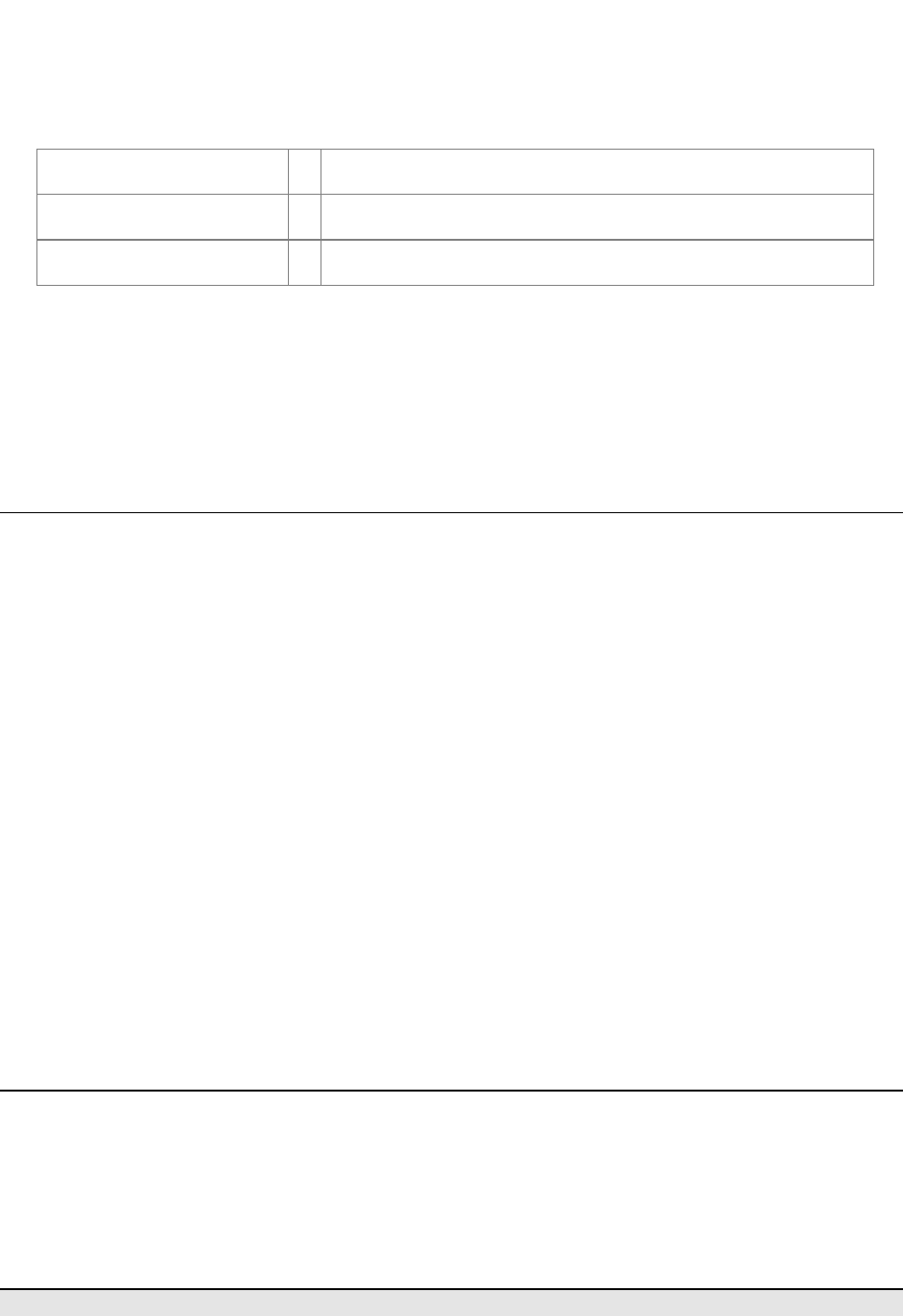

Material

:

Carcinogenicity Classification

Shell Heat Transfer Oil S2 X

MSDS# 17032

Version 1.1

Material Safety Data Sheet

Effective Date 02/05/2014

According to OSHA Hazard Communication Standard, 29 CFR

1910.1200

7/9

Print Date 02/07/2014 000000020351

MSDS_US

Highly refined mineral oil

(IP346 <3%)

: ACGIH Group A4: Not classifiable as a human carcinogen.

Highly refined mineral oil

(IP346 <3%)

: IARC 3: Not classifiable as to carcinogenicity to humans.

Highly refined mineral oil

(IP346 <3%)

: GHS / CLP: No carcinogenicity classification

Reproductive and

Developmental Toxicity

: Not expected to be a hazard.

Additional Information

: Used oils may contain harmful impurities that have

accumulated during use. The concentration of such impurities

will depend on use and they may present risks to health and

the environment on disposal. ALL used oil should be handled

with caution and skin contact avoided as far as possible.

12. ECOLOGICAL INFORMATION

Ecotoxicological data have not been determined specifically for this product. Information given is

based on a knowledge of the components and the ecotoxicology of similar products. Unless

indicated otherwise, the data presented is representative of the product as a whole, rather than

for individual component(s).

Acute Toxicity

: Poorly soluble mixture. May cause physical fouling of aquatic

organisms. Expected to be practically non toxic: LL/EL/IL50 >

100 mg/l (to aquatic organisms) LL/EL50 expressed as the

nominal amount of product required to prepare aqueous test

extract. Mineral oil is not expected to cause any chronic effects

to aquatic organisms at concentrations less than 1 mg/l.

Mobility

: Liquid under most environmental conditions. If it enters soil, it

will adsorb to soil particles and will not be mobile. Floats on

water.

Persistence/degradability

: Expected to be not readily biodegradable. Major constituents

are expected to be inherently biodegradable, but the product

contains components that may persist in the environment.

Bioaccumulation

: Contains components with the potential to bioaccumulate.

Other Adverse Effects

: Product is a mixture of non-volatile components, which are not

expected to be released to air in any significant quantities. Not

expected to have ozone depletion potential, photochemical

ozone creation potential or global warming potential.

13. DISPOSAL CONSIDERATIONS

Material Disposal

: Recover or recycle if possible. It is the responsibility of the

waste generator to determine the toxicity and physical

properties of the material generated to determine the proper

waste classification and disposal methods in compliance with

applicable regulations. Do not dispose into the environment, in

drains or in water courses.

Shell Heat Transfer Oil S2 X

MSDS# 17032

Version 1.1

Material Safety Data Sheet

Effective Date 02/05/2014

According to OSHA Hazard Communication Standard, 29 CFR

1910.1200

8/9

Print Date 02/07/2014 000000020351

MSDS_US

Container Disposal

: Dispose in accordance with prevailing regulations, preferably

to a recognised collector or contractor. The competence of the

collector or contractor should be established beforehand.

Local Legislation

: Disposal should be in accordance with applicable regional,

national, and local laws and regulations.

14. TRANSPORT INFORMATION

US Department of Transportation Classification (49CFR)

This material is not subject to DOT regulations under 49 CFR Parts 171-180.

IMDG

This material is not classified as dangerous under IMDG regulations.

IATA (Country variations may apply)

This material is either not classified as dangerous under IATA regulations or needs to follow

country specific requirements.

15. REGULATORY INFORMATION

The regulatory information is not intended to be comprehensive. Other regulations may apply to this

material.

Federal Regulatory Status

Notification Status

EINECS All components listed or

polymer exempt.

TSCA All components listed.

DSL All components listed.

Shell classifies this material as an "oil" under the CERCLA Petroleum Exclusion, therefore

releases to the environment are not reportable under CERCLA.

SARA Hazard Categories (311/312)

No SARA 311/312 Hazards.

Shell Heat Transfer Oil S2 X

MSDS# 17032

Version 1.1

Material Safety Data Sheet

Effective Date 02/05/2014

According to OSHA Hazard Communication Standard, 29 CFR

1910.1200

9/9

Print Date 02/07/2014 000000020351

MSDS_US

State Regulatory Status

California Safe Drinking Water and Toxic Enforcement Act (Proposition 65)

This material does not contain any chemicals known to the State of California to cause cancer, birth

defects or other reproductive harm.

16. OTHER INFORMATION

NFPA Rating (Health,

Fire, Reactivity)

: 0, 1, 0

SDS Version Number

: 1.1

SDS Effective Date

: 02/05/2014

SDS Revisions

: A vertical bar (|) in the left margin indicates an amendment

from the previous version.

SDS Regulation

: The content and format of this MSDS is in accordance with the

OSHA Hazard Communication Standard, 29 CFR 1910.1200.

SDS Distribution

: The information in this document should be made available to

all who may handle the product.

Disclaimer

: The information contained herein is based on our current

knowledge of the underlying data and is intended to describe

the product for the purpose of health, safety and environmental

requirements only. No warranty or guarantee is expressed or

implied regarding the accuracy of these data or the results to

be obtained from the use of the product.