Replacement Window

Installation Guide

Windows without Nailing Fin

tmhsdch

o5

WWW

Project Requirements:

•

Failure to follow these

instructions may void product

warranty.

•

Read guide before starting

installation. Read all warnings

and cautions during installation.

•

Due to ongoing product

changes, updated test results

and/or new industry best

practices, this installation

procedure may change over time.

Visit the manufacturer's website

for current installation

instructions.

•

This product is designed to be

used as a replacement window

installed into an existing “old

style” wood double-hung

window frame.

•

Installation must comply with all

applicable building codes.

•

Existing window frame, wall and

weather-resistant barrier must be

adequate and window frame and

wall must be structurally sound.

•

Window must be installed to be

plumb, level and square.

•

The replacement window should

be approximately 1/4" less in

width and height than the

existing window opening once

the old sash and components

have been removed. Head

expander can be used if up to

1/2" less in height.

•

Instructions are given for

installation from the interior of

the building.

•

Contact local authorities or

waste management companies

for proper recycling and/or

disposal of removed window or

patio door.

•

Visit the manufacturer’s web

site for removal instructions,

additional installation

information and/or guides.

tmhsdcvq“h’““f”

o5

”“

WWWTT

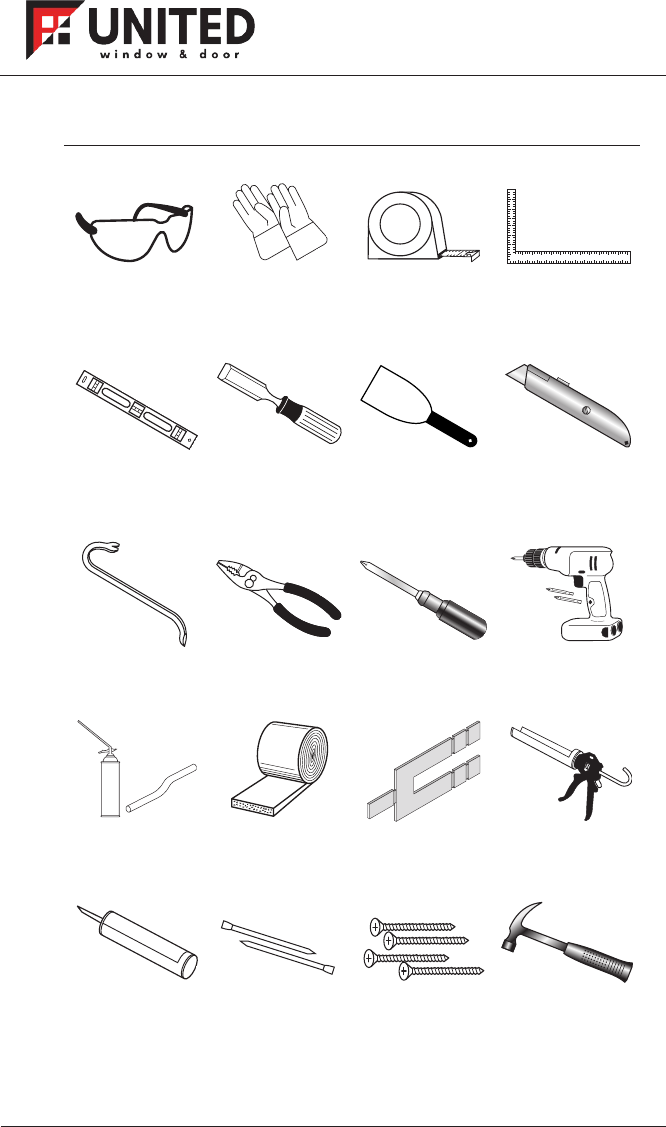

Tools & materials required:

Safety glasses Work gloves Tape measure Framer’s square

4' level Chisel Putty knife Utility knife or other

cutting tool

(as needed)

Pry bar Pliers Phillips hand

screwdriver

Power driver

and bits

Backer rod/

Minimum expanding

foam sealant

Fiberglass insulation Shims Caulk gun

Interior and exterior

window grade

sealant

Finish nails

4 - #8 x 2" flat head

screws (for single-

hung window

installation only)

Hammer

thsdchf

o5

Warnings and Cautions:

Do not drill or fasten

through sill. Product and/or

property damage will result

Do not overdrive screws or

nails. Product damage may

result.

Do not overfill with low

expanding foam or over-pack

with backer rod to avoid bowed

jambs.

Do not leave the window

opening unattended, especially

when small children are present.

A fall from the window opening

could cause death or serious

injury.

Unless specifically ordered,

this window does not have safety

glass, and if broken, could cause

injury. Many laws and building

codes require safety glass in

locations adjacent to or near

doors. This window is available

with safety glass that may reduce

the likelihood of injury if broken.

Information on safety glass is

available from your sales

representative.

tmhsdchf

o5

Use caution when working at

elevated heights and around unit

openings. Follow manufacturers

instructions for ladders and/or

scaffolding. Failure to do so may

result in injury or death.

Follow manufacturer

instructions for hand or power tools.

Always wear safety glasses. Failure

to do so may result in injury and/or

product damage.

Windows and doors can be

heavy. Use safe lifting techniques

and a reasonable number of people

with enough strength to lift, carry

and install window and door

products to avoid injury and/or

product damage.

Sill weep doors are small parts

and, if swallowed, could pose a

choking hazard to young children.

Support window in opening

while shimming. Failure to do so

may result in injury and/or product/

property damage.

Do not position sash at a 90°

angle. Sash may disengage from

frame and may cause injury.

Contains small parts. If

swallowed could pose a choking

hazard to young children. Remove

and dispose of any loose or easily

removed parts.

Before, during, and after

installation, place all tools as well as

any casing or window parts on a

drop cloth or in a location that will

not pose a hazard to installers,

customers, or property.

Warnings and Cautions:

Remove or cut ventilation

holes in plastic shipping wrap if

window is not installed

immediately or product damage

may occur.

Do not store windows flat or in

the sun or product damage may

occur.

Use masonry screw when

fastening directly into masonry or

through a buck into masonry.

Do not cover weep holes.

Property damage may result.

The use of movable

insulating materials such as

window coverings, shutters, and

other shading devices may

damage glass and/or vinyl.

Follow instructions of foam,

sealant and flashing

manufacturer regarding material

application and compatibility

with this product.

Do not apply any type of film

to glass. Thermal stress

conditions resulting in glass

damage could occur.

Weep holes must face the

exterior and must be located at

the bottom of the window or

product and/or property damage

may occur.

When insulating between

unit frame and rough opening or

between units when joining, DO

NOT over-pack batt insulation or

overfill with foam.

Bowed jambs will result

affecting product performance

and/or proper operation of unit.

Buildings constructed prior to 1978

may contain lead paint which could

be disturbed during replacement.

For more information on proper

management of lead paint, visit

www.epa.gov/lead

Important safety information.

Leave this information for the

building occupant.

tmhsdcvhf

o5

Finishing, Cleaning and Maintenance Instructions:

Do not stain or paint weatherstrip,

vinyl, glass or hardware. Product

damage may occur.

▶ Read and follow finishing product

instructions and warnings on finish

material.

Acid solutions used for cleaning

masonry or concrete will damage

glass, fasteners, hardware, vinyl and

metal flashing.

Protect unit and follow cleaning

product instructions carefully. If acid

contacts unit, wash all surfaces with

water immediately.

Abrasive cleaners will damage

glass and vinyl surfaces.

▶ Clean glass us

ing liquid glass

cleaner.

▶ Clean exterior frame, sash, and

insect screens using mild

detergent and water with a soft

cloth or brush.

▶ For hard to clean areas use a

nonabrasive cleaner, alcohol-

and-water or ammonia-and-

water.

▶ Do not apply any type of film to

insulating glass. Thermal stress

and glass damage can result.

Shading devices (insulated

coverings, shutters, etc.) may

also cause thermal stress

damage.

▶ For continued weather resistance

of sealant joints, follow the

sealant manufacturer’s

recommendations for periodic

maintenance.

Metal fasteners and components may corrode when exposed to

preservative-treated and/or fire-retardant treated lumber. Use approved

fasteners and components to fasten unit. Failure to do so may cause a

failure resulting in injury, property or product damage.

Fasteners:

tmhsdcvhf

oU5

M

MM

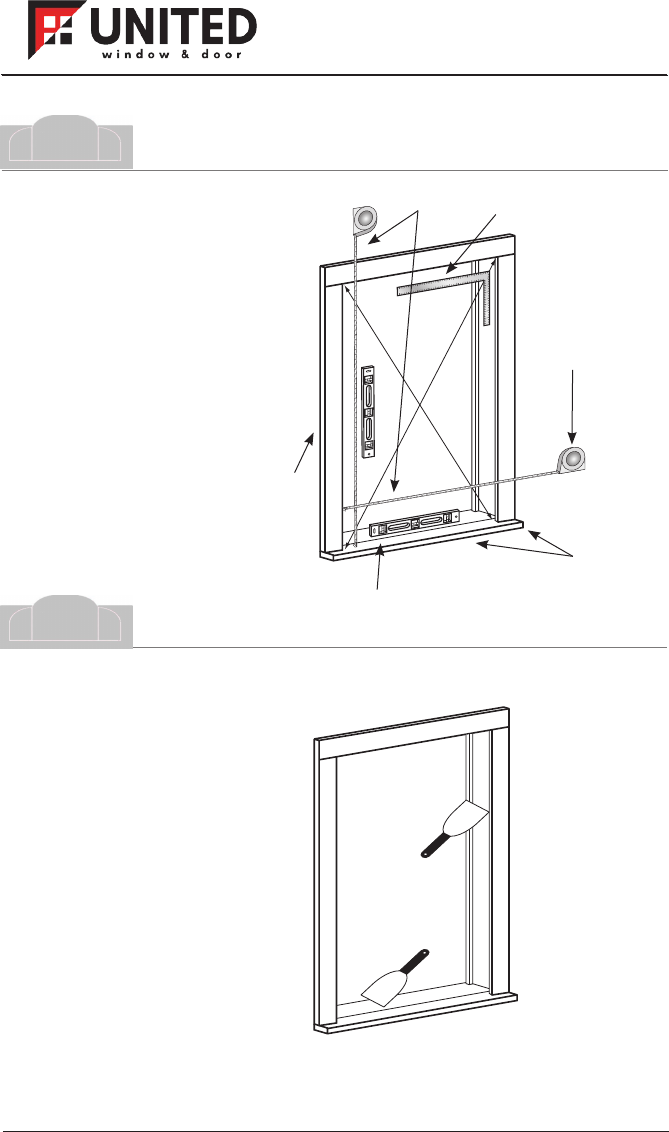

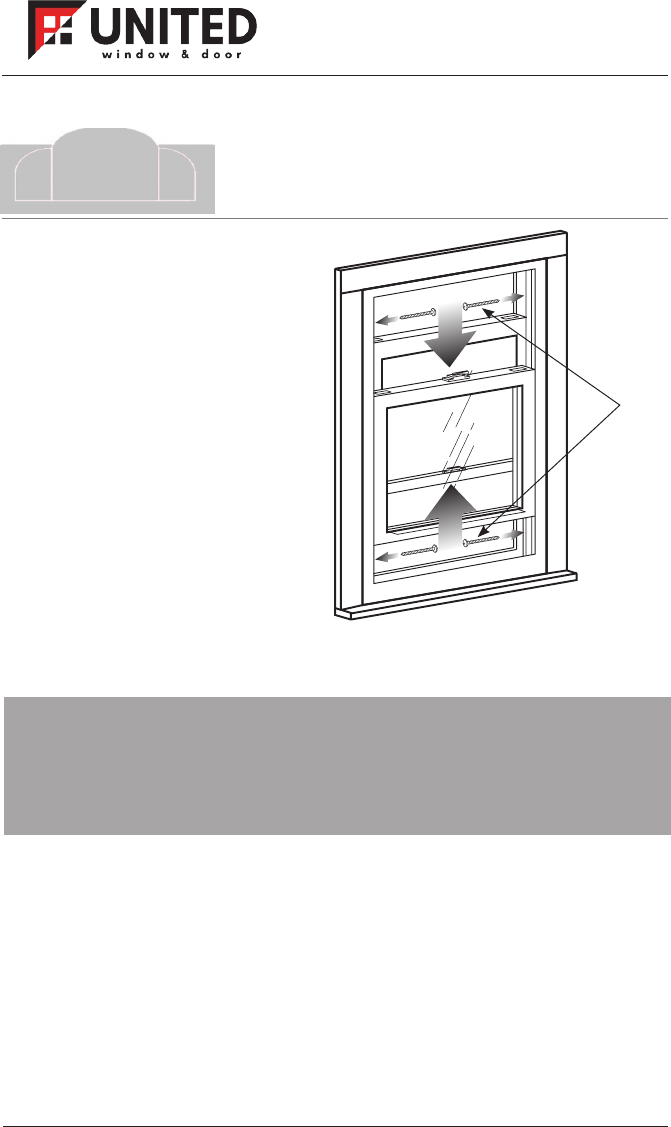

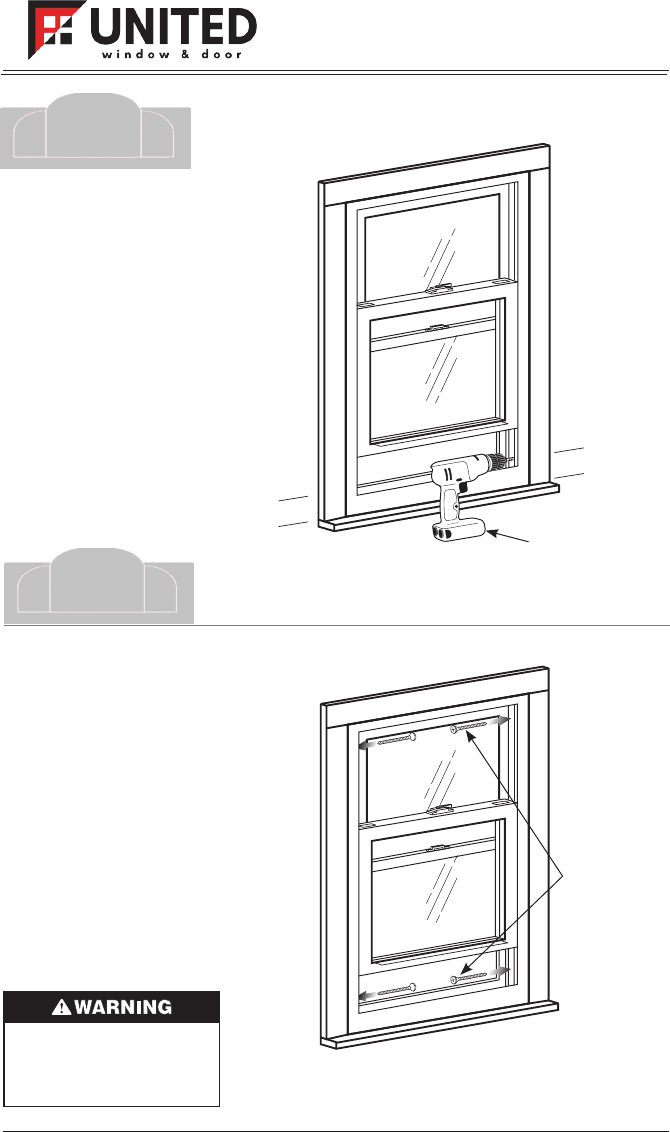

Step 1

One hardware bag containing:

Quantity Item

4 #8 x 2" Pan Head Screws

Hardware Included:

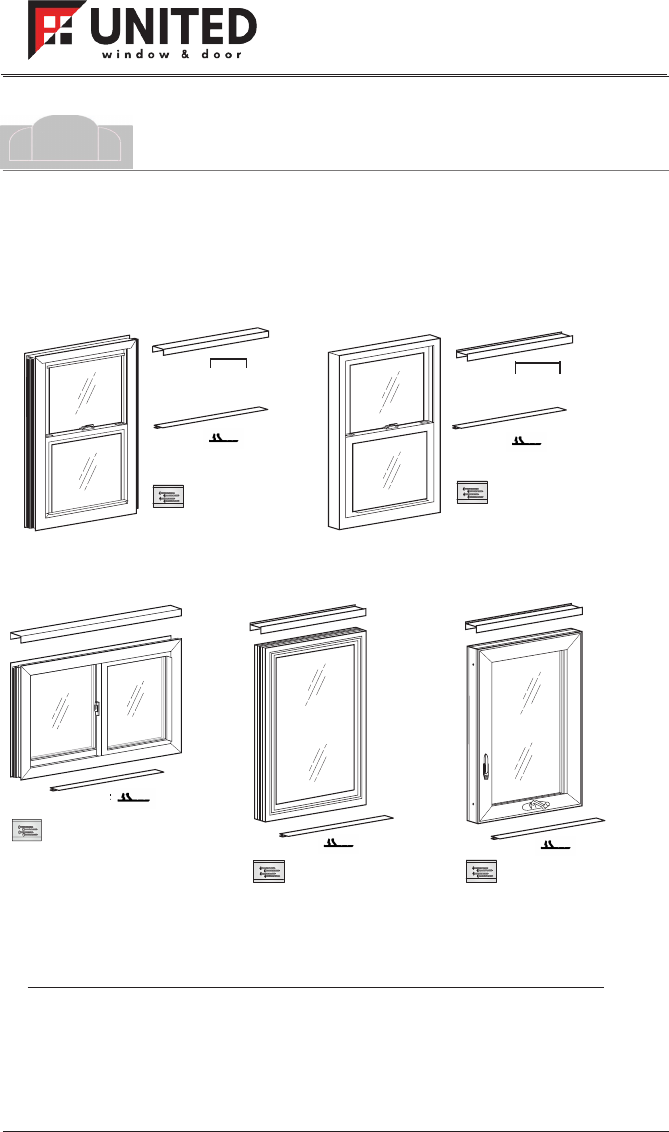

Single-Hung WindowDouble-Hung Window

Inspect new window and verify opening.

Inspect for proper size and condition and verify that all parts are included. Inspect

existing wall and rough opening for structural decay. Repair as needed.

Replacement Windows

Head expander

Sill angle

(appropriate part included)

Screw bag

Screw bag

Screw bag Screw bag

Head expander

Screw bag

Sill angle

(appropriate part included)

Sill angle

Head expander

Sliding Window

Picture Window

Sill angle

Head expander

Casement/Awning Window

Sill angle

Head expander

Interior

Interior

Interior Interior

Interior

thsdcvhf

o75

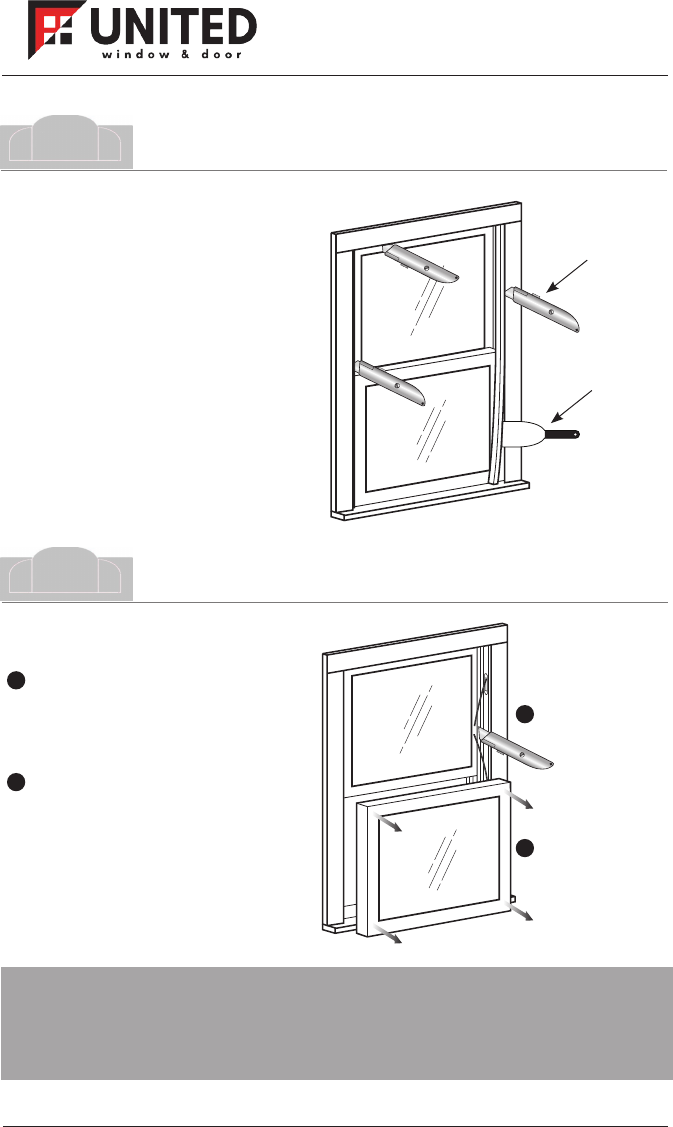

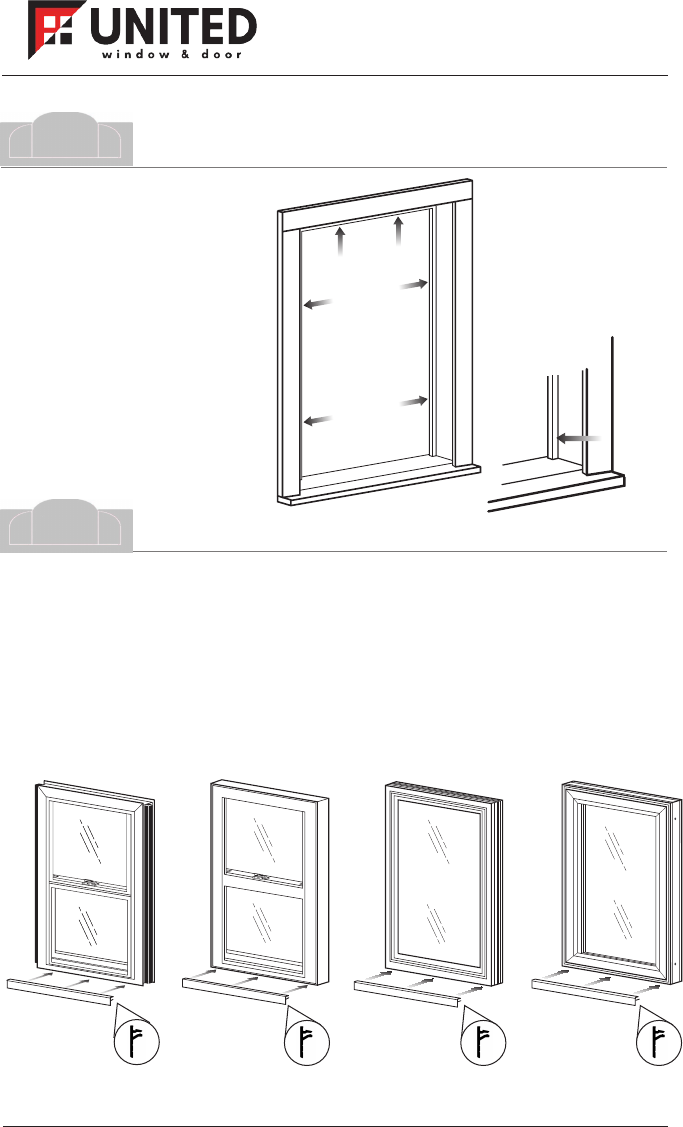

Step 2

Remove interior stops.

Carefully remove interior

stops and save for later use.

Utility knife

Cut

Remove

Putty knife

NOTE: If old window opening has wood top and side

parting stops, proceed to Step 4 Wood Stops. If opening has

metal tracks on the sides, proceed to Step 6 Metal Tracks.

Step 3

Remove bottom sash.

Cut bottom sash balance

cords, if present. Balance

systems may vary.

Remove bottom sash and

dispose of properly.

1

1

2

2

Interior

Interior

tmhsdcvhf

o85

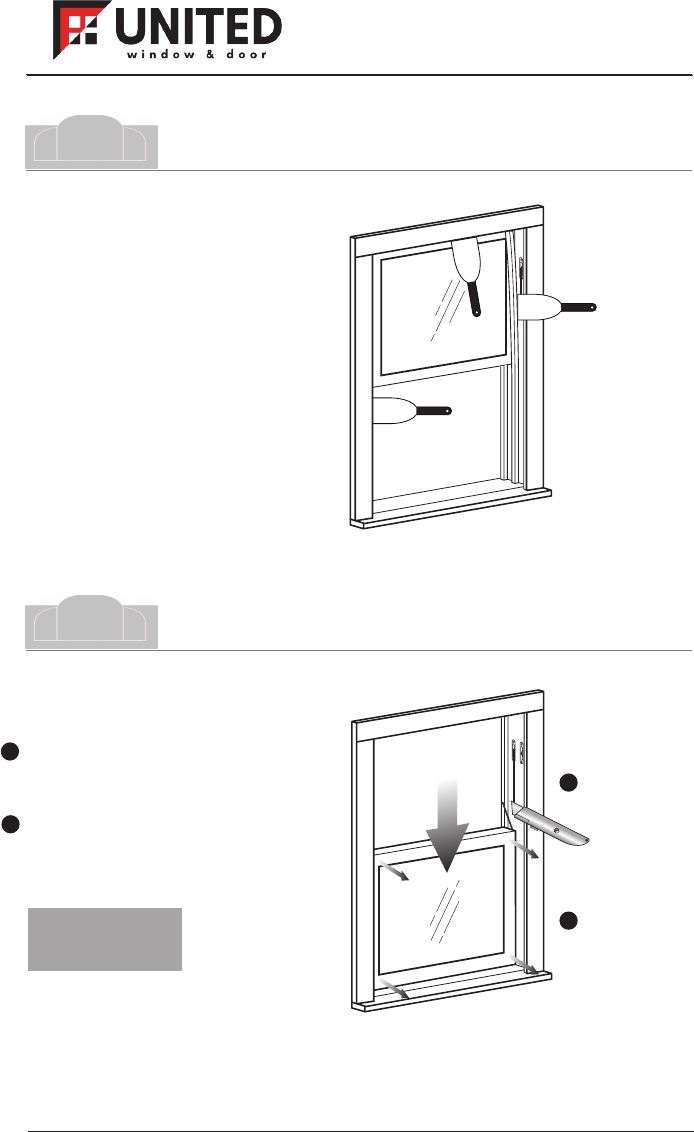

Step 4

Remove top and side

parting stops.

Remove top and side

wood parting stops and

dispose of properly.

Step 5

Wood Stops

Remove top sash.

Lower top sash to sill.

Cut top sash balance

cords, if present. Balance

systems may vary.

Remove top sash and

dispose of properly.

Interior

Interior

tmsdvf

o95

Wood Stops

NOTE: Proceed to

Step 7.

Cut

1

Remove

2

1

2

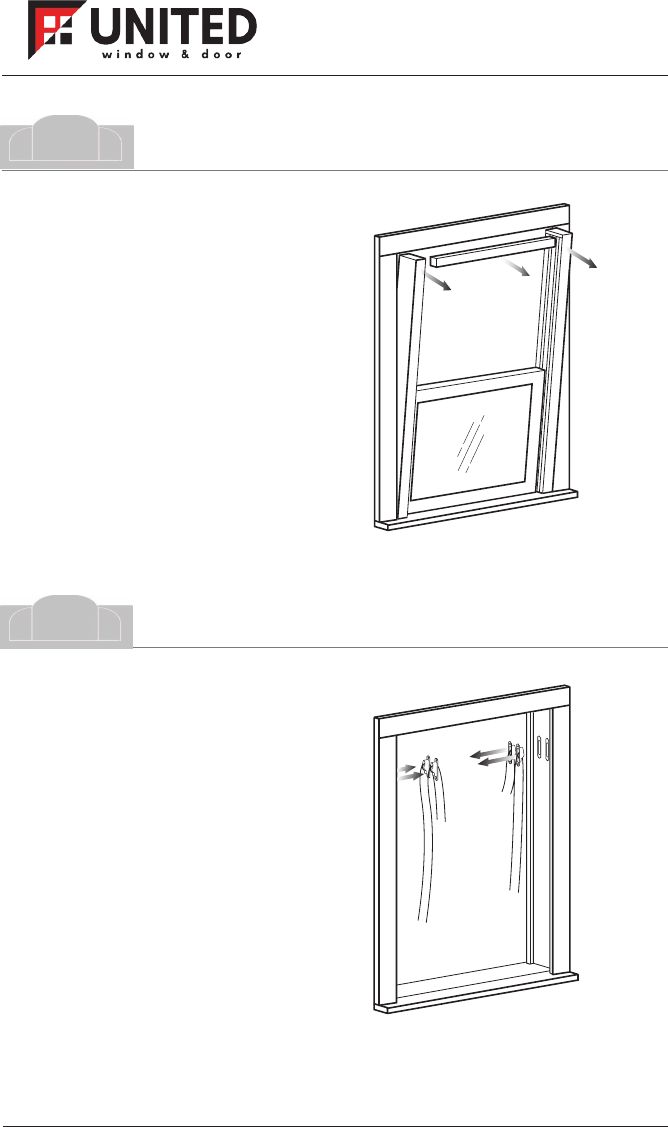

Remove old balance

system.

Remove old balance

system including any

pulleys and dispose of

properly.

Remove tracks

and top sash.

Lower top sash to sill.

Remove top wood parting

stop.

Remove fasteners that

attach metal tracks/jamb

liners to the sides.

Remove metal tracks and

top sash together and

dispose of properly.

Be careful when removing

metal tracks/jamb liners

as springs may be under

tension.

Interior

Interior

tmhsdcvhf

o05

Step 6

Metal Tracks

Step 7

Interior

Inspect opening.

Make sure opening is

structurally sound.

Measure the opening at

the smallest width and

height, vertically and

horizontally to verify size.

Remember to check to

make sure the opening is

square by measuring

diagonally.

Measurements must be

within 1/8".

Framer's square

Tape

measure

Plumb

Level

Correct size

Inspect to

make sure no

visible water

leakage.

Prepare opening.

Clean opening of all

debris.

Remove any protruding

fasteners.

Insulate any large areas as

needed.

Cover or fill all holes as

needed.

Interior

tmhsdcvqhf

o15

M

MM

Step 9

Step 8

Verify blind stop.

Leave existing blind stop

intact.

If any portion of the

blind stop is damaged,

the entire stop will need

to be replaced.

Install sill angle if needed.

I

f sill of existing window opening is slanted, install supplied sill angle in

the groove on the bottom of the window. Determine appropriate sill

angle placement for either double-hung or single-hung as shown.

Exterior

Double-Hung

and Sliding

Sill angle

Blind

stop

Sill

Single-Hung

Sill angle Sill angle Sill angle

Interior

Picture

Casement

and Awning

tmhsdcvhf

o25

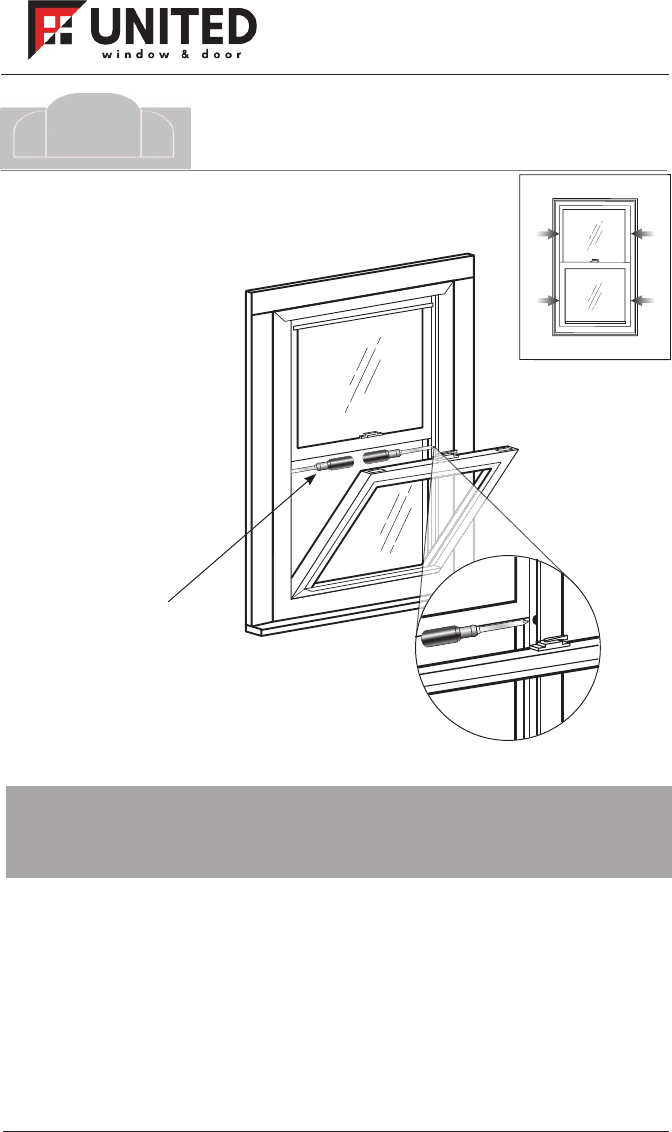

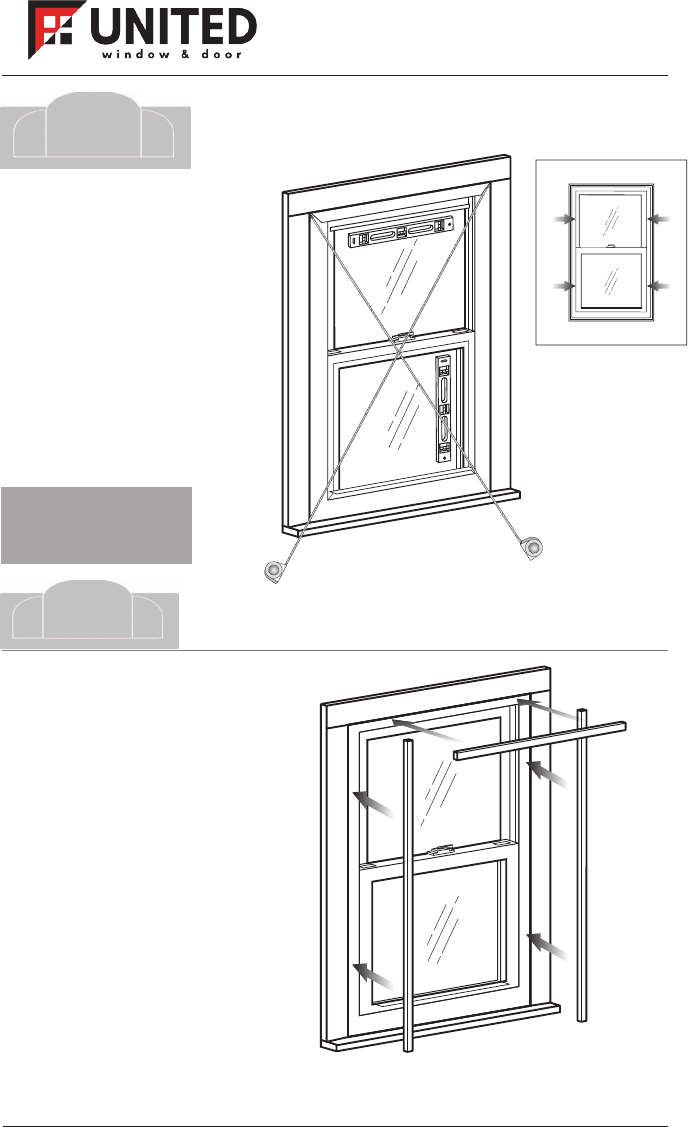

Step 10

Step 11

Check fit of window.

Temporarily place window

into opening tilting in from

bottom and check for fit.

Then remove window.

Adjust and trim sill angle as

needed.

NOTE: Shown with optional

head expander.

Exterior

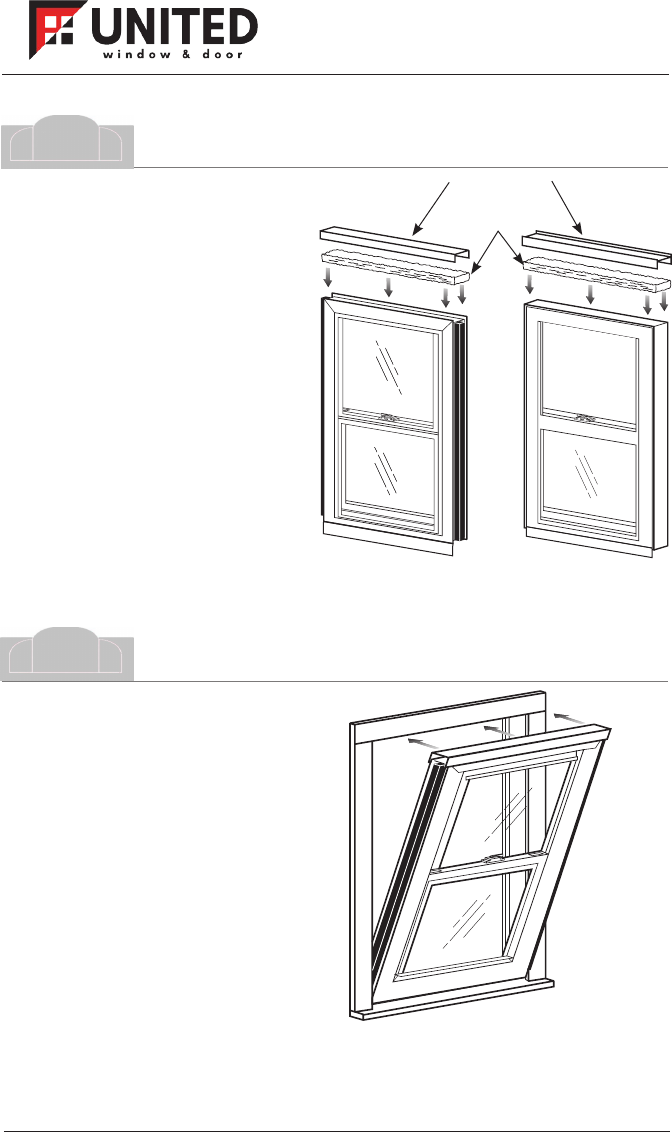

Install head expander

if needed.

If the height of the window

opening is higher than

what will be covered with

interior stops, then place

the supplied head

expander on top of the

window as shown.

It is recommended to add

fiberglass insulation

between head expander

and window.

NOTE: Procedure is

identical for double-hung,

single-hung, sliding,

picture, casement or

awning windows.

Double-Hung Single-Hung

Head expander

Insulation

Interior

tmhsdcvhf

oP35

OOSSTTO

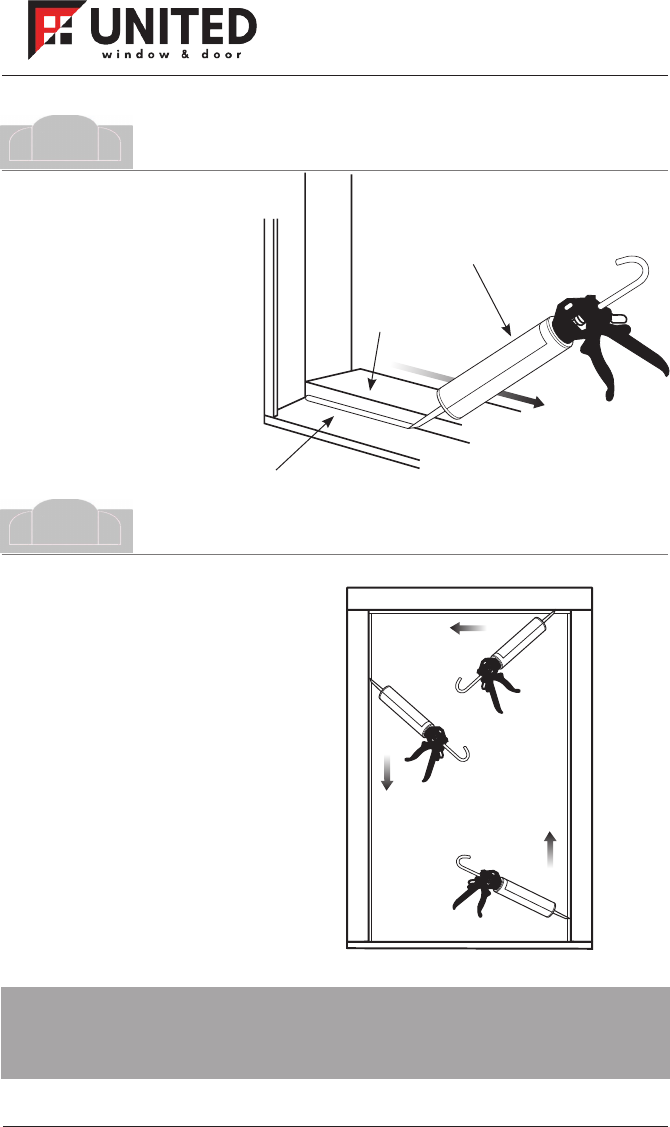

Step 12

Step 13

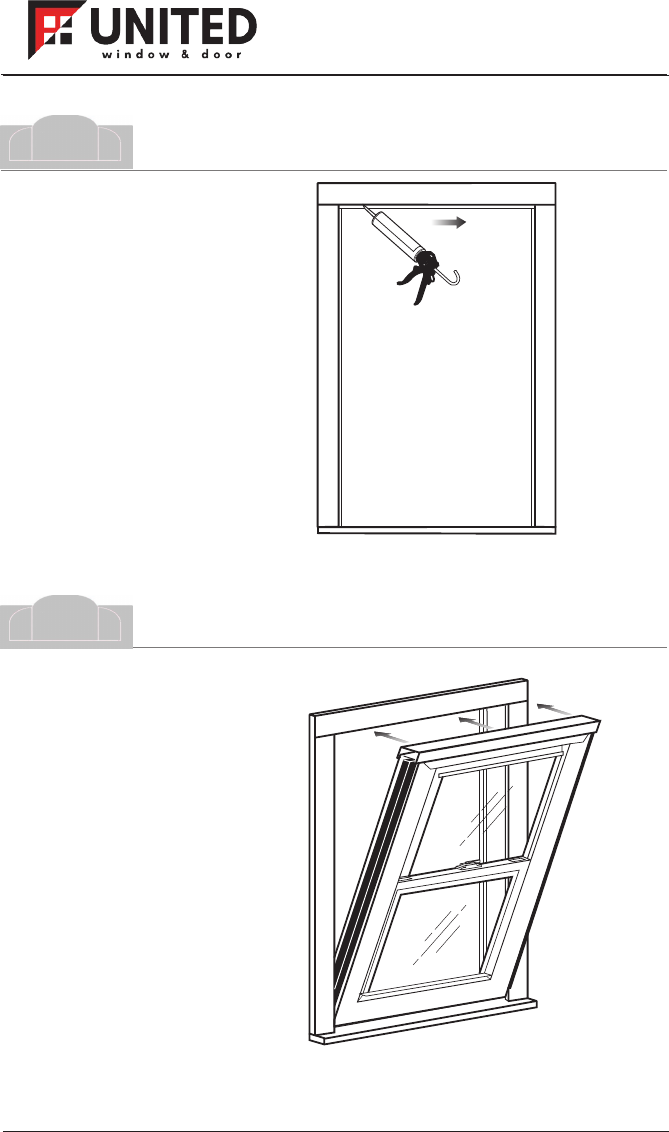

Apply sealant to blind

stop.

Apply 3/8" bead of

sealant to inside edge of

blind stop at top and

both sides.

Apply sealant to sill.

Apply 3/8" bead of

sealant where the

existing stool meets the

window sill.

Caulking gun

and sealant

Stool

Window

sill

Interior

Exterior

If using optional head expander, continue with Step 16. If

not using optional head expander, proceed to Step 17.

thsdhf

o4 5

Step 14

Step 15

Apply sealant to head

of window for optional

head expander.

Apply 3/8" bead of

sealant to top of window

frame in middle across

the entire width of the

opening if using head

expander.

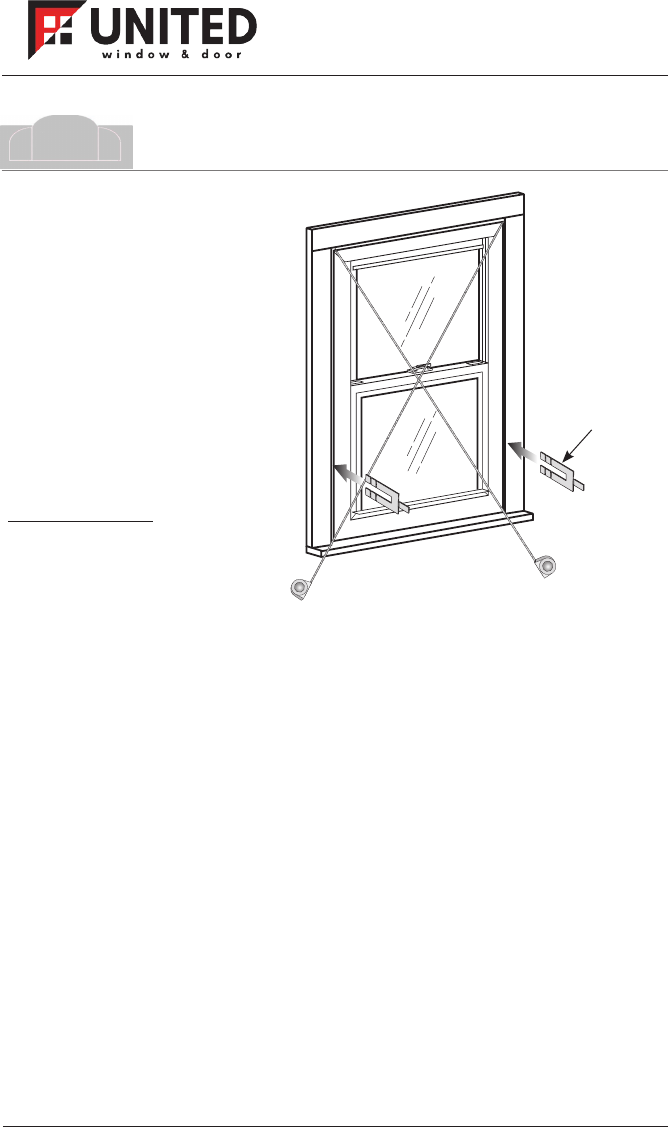

Place window into

opening.

Place window into

opening, tilting in from

bottom.

Make sure sill angle and

head expander remain in

place if present.

The bottom interior edge

of the window should sit

tight against the stool.

If present, the head

expander should be

pushed up to meet the

top of the opening.

NOTE: Shown with

optional head expander.

Interior

Interior

tmhsdchf

o55

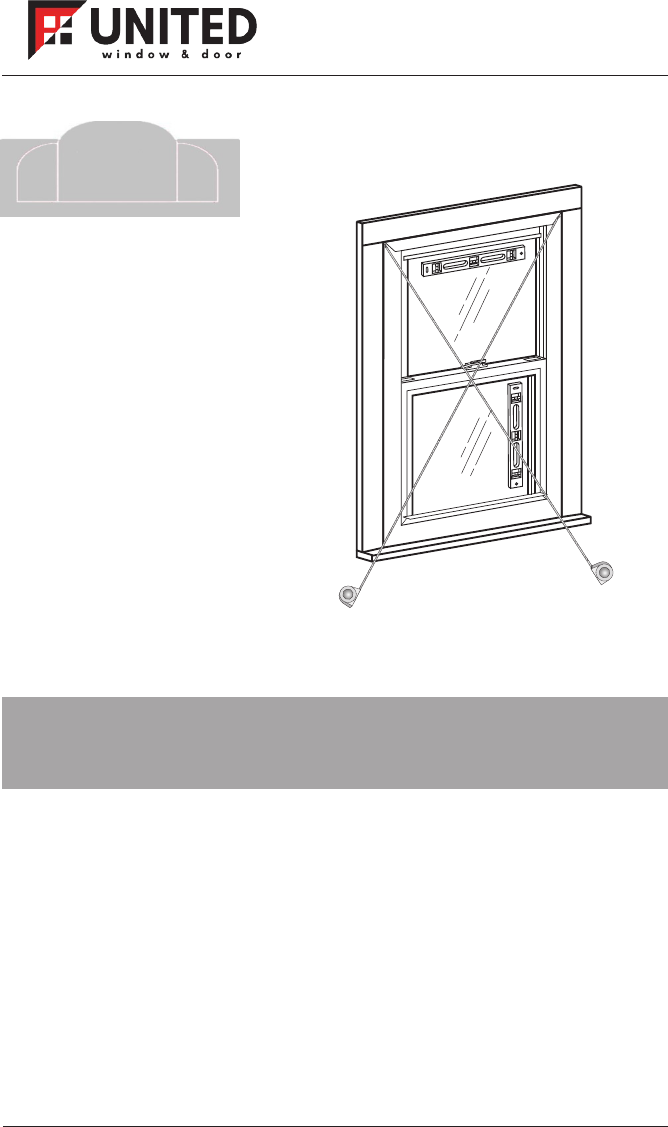

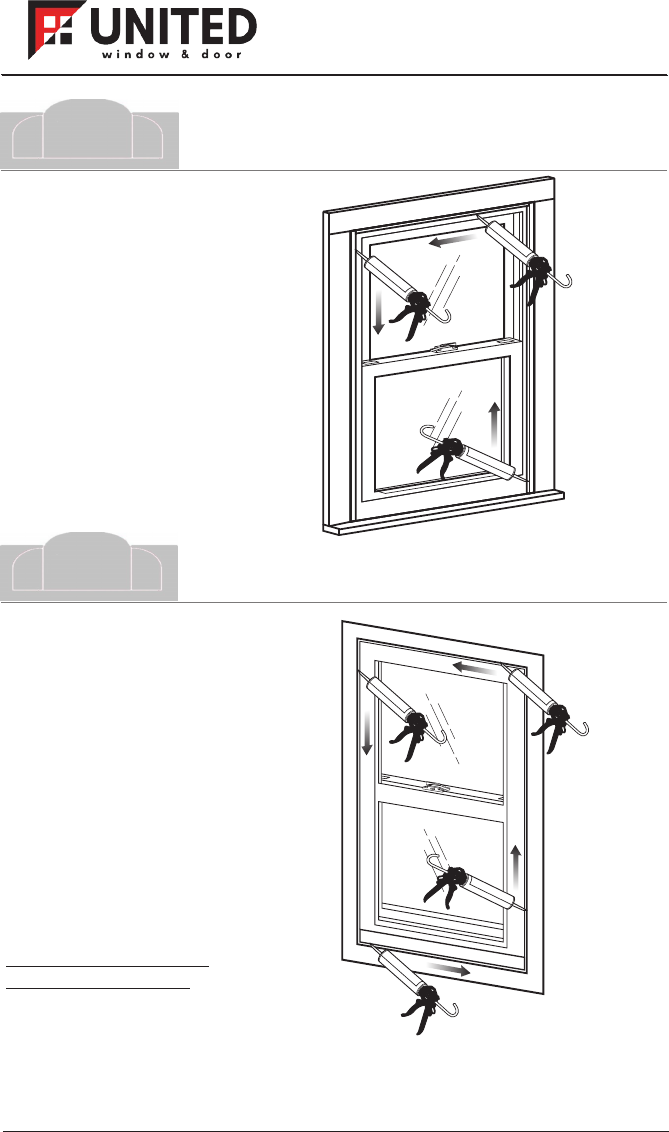

Step 16

Step 17

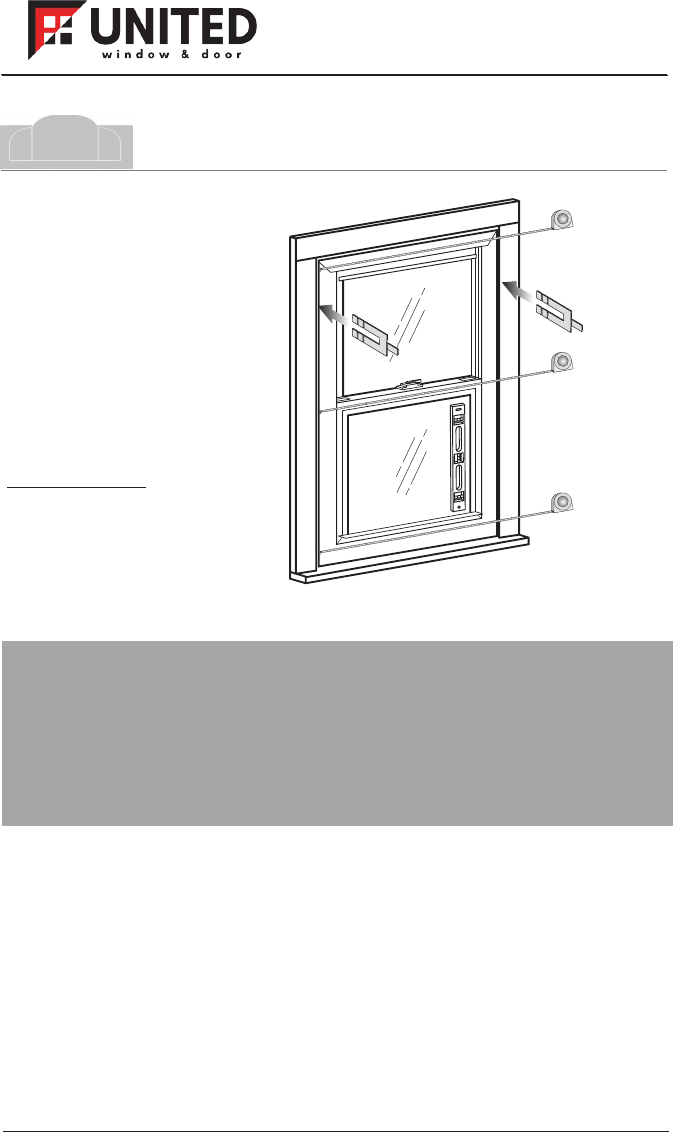

Check for square.

Close and lock window.

Measure diagonally

across unit, upper left to

lower right and upper

right to lower left corner.

If measurements are

within 1/8", unit is square.

If unit is not square, adjust

by inserting shims as

needed.

Do not over shim.

Shim

Interior

tmhsdcvqhf

o6 5

M

MM

Step 18

Check for plumb.

Measure across head,

center and sill of unit.

Center dimensions should

match head and sill

dimensions within 1/8".

Check for plumb.

Shim to straighten side

jambs as needed.

Do not over shim

Interior

tmhsdcvhf

oP75

M

OOMSMSTTO

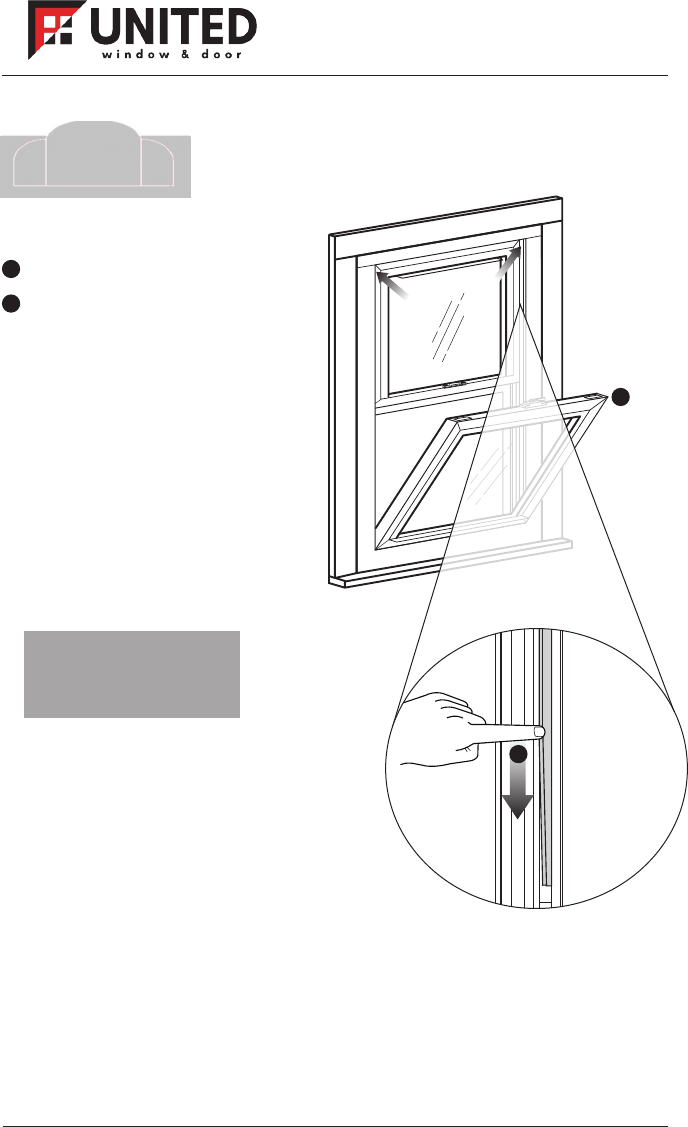

Step 19

NOTE: If installing a double-hung window proceed to step

20 Double Hung. If installing a sliding, picture, casement or

awning window, proceed to Step 21 Double-Hung, Sliding,

Picture, Casement or Awning. If installing a single-hung

window, proceed to Step 27 Single-Hung.

Balance

cover

1

2

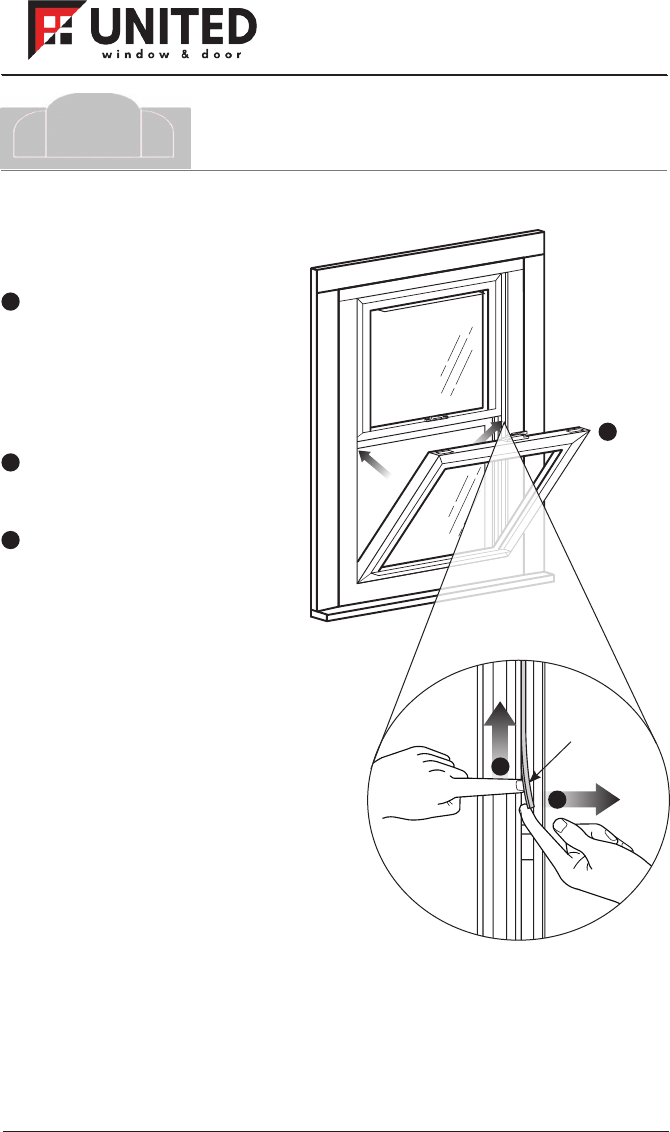

Remove balance

covers to access

screw holes.

To access the balance

covers, unlock and

partially raise the

bottom sash. Slide tilt

latches and tilt the

bottom sash in. Rest

sash on sill.

Place your index finger

at the bottom edge of

the balance cover.

Pull the balance cover

out of the jamb

channel.

Repeat to remove the

other balance cover.

Then tilt the bottom sash

back into place.

Save both balance covers

to re-install later.

1

2

3

3

Interior

Step 20

Double Hung

Balance Covers

tmhsdcvhf

o185

SSTT

21

#8 x 2"

Pan head

screws

Step 21

Double-Hung, Sliding,

Picture, Casement

or Awning

Fasten window.

Unlock window and open

sash to access screw

holes.

Install supplied #8 x 2"

pan head screws into the

2 screw holes in each

jamb.

Do not over tighten as

this may distort the

frame.

Interior

NOTE: If installing a double-hung window, proceed to Step

22 Double-Hung. If installing a sliding, picture, casement or

awning window, proceed to Step 24 Double-Hung, Sliding,

Picture, Casement or Awning.

tmhsdcvhf

o195

NOTE: Proceed to Step 23 Double-Hung, Sliding, Picture,

Casement or Awning.

Phillips

screwdriver

Adjust sides.

To access the jamb

adjusting screws, unlock

and partially raise the

bottom sash.

Slide tilt latches and tilt

the bottom sash in.

Tighten the jamb

adjusting screws located

in the middle of the sides

until the sight lines

between the frame and

sash are equal and

uniform.

Then tilt the bottom sash

back into place.

Step 22

Double-Hung

Interior

tmhsdcqhf

o05

OOSSTTO

Interior

Step 23

Double-Hung,

Sliding, Picture,

Casement or Awning

Check window

placement.

Close and lock window.

Check window for plumb,

level and square.

Diagonal measurements

must be within 1/8".

Check sight lines.

Check sash operation.

Adjust screws and shims

as needed

tmhsdcvqhf

o15

NOTE: If installing a double-hung window, proceed to Step 24

Double-Hung. Otherwise proceed to Step 28.

Step 24

Double-Hung

Balance Covers

Install balance covers.

Tilt the bottom sash in.

Position the balance cover

into the jamb, and make

sure it is tight against the

head of the unit.

Insert the top portion of the

balance cover into the jamb.

Once attached, slide your

finger along the balance

cover down toward the sill,

compressing the balance

cover into the side jamb.

Repeat to install the other

balance cover.

1

1

2

2

Interior

NOTE: Proceed to

Step 28.

tmhsdcvhf

o25

OOTTO

Step 25

Single-Hung

Drill installation

holes.

Open bottom sash.

Drill one 3/32"

installation hole in each

side approximately 2" up

from the bottom to

penetrate structural

supports at least 1".

Power

driver

2"

2"

Interior

#8 x 2"

Flat head

screws

Step 26

Single-Hung

Fasten window.

Install #8 x 2" flat head

screws (not supplied) into

the 2 screw holes in each

jamb.

Do not over tighten as this

may distort the window.

Do not damage balance

cords.

Make sure screw heads

are flush with surface of

window to prevent

interference with sash

operation.

Use caution to avoid

damage to balance cords.

Product failure may result.

Interior

tmhsdcvhf

o35

M

OOMMO

Step 27

Single-Hung

Interior

Step 28

Apply interior stops.

Replace or add, if needed,

interior stops against the

window.

Be careful to not damage

the window.

Interior

tmhsdcvqhf

o45

Check window

placement.

Close and lock window.

Check window for plumb,

level and square.

Diagonal measurements

must be within 1/8".

Check sight lines. Check

sash operation.

Adjust screws and shims

as needed.

NOTE: Proceed to

Step 30.

Step 30

Apply sealant to

exterior.

Apply exterior grade

sealant to the exterior of

window where window

meets framed opening

around entire perimeter.

Fill any old screw holes.

Take care to make sure

that all gaps and holes are

sealed between the

window and the wood

frame.

Do not cover weep holes

on bottom of window.

Exterior

Step 29

Apply sealant to

interior.

Apply interior grade

sealant to the interior of

the window where the

interior stops meet the

window and where the

head expander, if present,

meets the window to seal

any gaps.

Interior

tmhsdcvhf

o55

TT